Battery bracket for new energy vehicle

A technology for battery brackets and new energy vehicles, applied in the field of auto parts, can solve problems such as increasing the probability of vibration problems, low strength and structural performance, stress concentration, etc. The effect of improving fatigue durability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

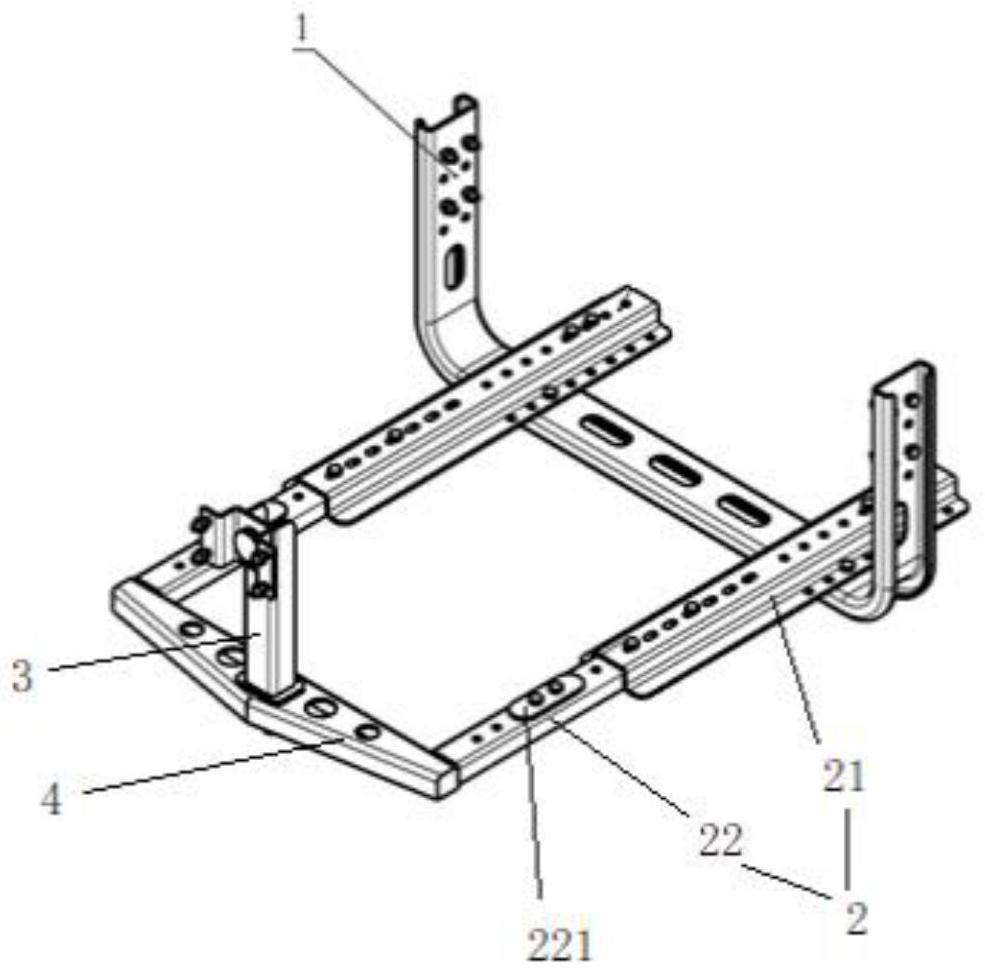

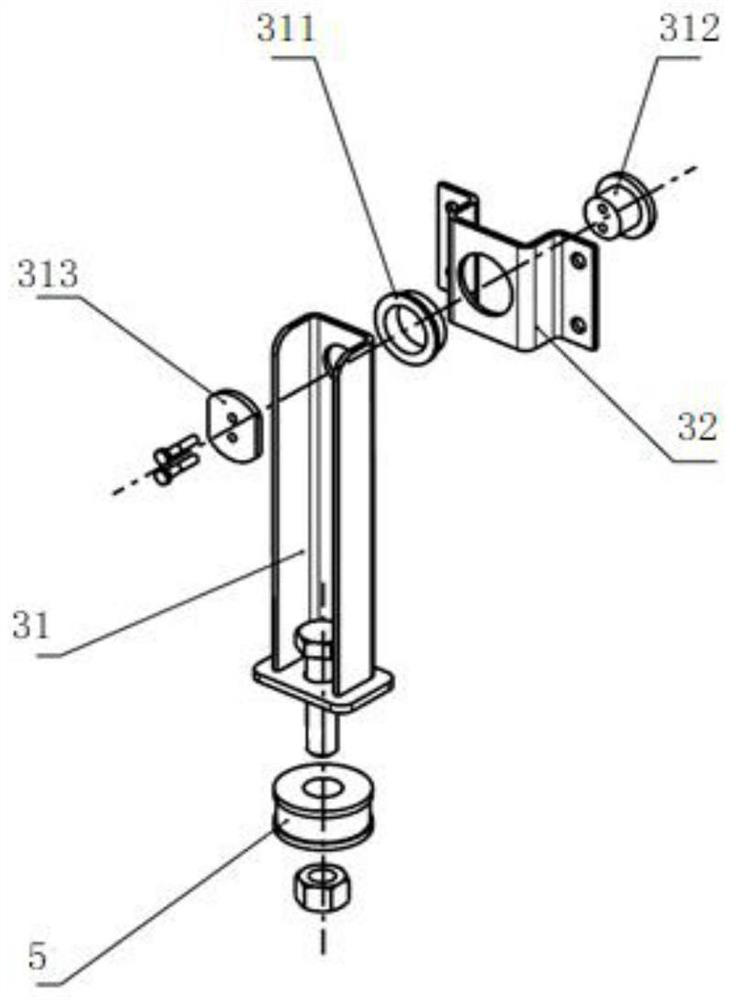

[0043] Such as Figure 1 to Figure 5 As shown, a battery bracket for new energy vehicles, including:

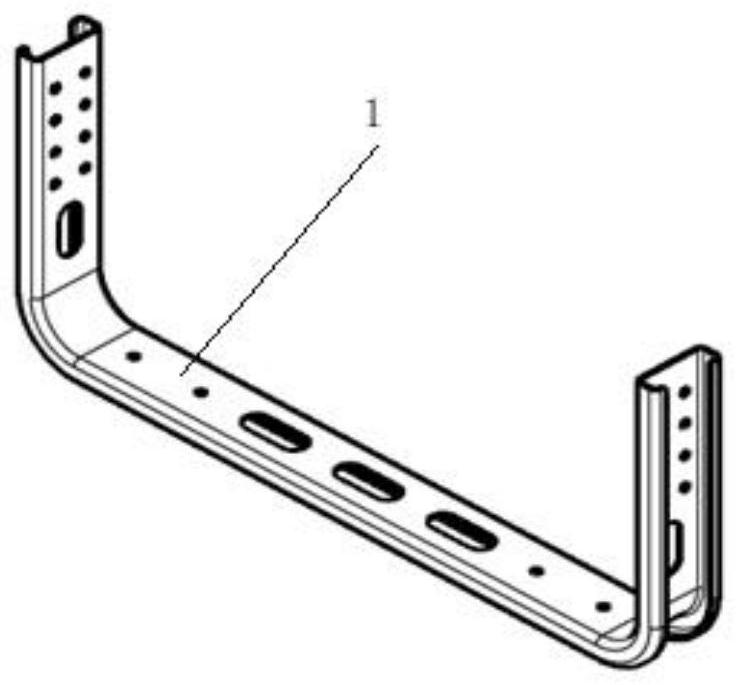

[0044] Two-point bracket 1, the two-point bracket 1 is set in a groove shape, and its two ends are fixedly connected with the vehicle frame; specifically, the cross-section of the two-point bracket 1 is C-shaped, with higher specific stiffness, and its two vertical There are multiple sets of bolt holes arranged on the side belly along the vertical side. The multiple sets of bolt holes are used to adjust the installation height of the battery pack when matched with the frame longitudinal beam. The beam web of the two-point bracket 1 is arranged along the axis of the beam web. Multiple notches are used to reduce weight while adjusting the structural stiffness of the beam web.

[0045]Telescopic beam 2, at least one telescopic connecting beam 22 is provided, and the telescopic beam 2 is fixedly connected with the two-point bracket 1; the telescopic beam 2 includes a telescopic ...

Embodiment 2

[0050] refer to Figure 6 to Figure 8 In this embodiment, except that "the single-point hanger 3 includes two second hanger vertical beams 33 and a second pin shaft 34 that runs through the two second vertical beams, the second pin shaft 34 is connected to a The second cover plate 35 and the two second hanger vertical beams 33 are fixedly connected with the two bracket beams 4 or the two telescopic beams 2 respectively; The limiting blocks 341 are engaged with the two second vertical beams 33 of the hanger respectively." The rest are identical to the first embodiment. Specifically, the two second hanger vertical beams 33 have the same structure, four limit blocks 341 are arranged and divided into two groups, each set of limit blocks 341 is located at the two ends of the second pin shaft 34, and two Two limit blocks 341 are arranged oppositely.

[0051] The specific working principle of this embodiment is: when two battery brackets are used together, the single-point hanger 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com