Machining method for improving ultrasonic flaw detection qualification rate of titanium alloy super-long seamless pipe

A technology for seamless pipes and processing methods, which is applied in the field of processing to improve the pass rate of titanium alloy ultra-long seamless pipes for ultrasonic flaw detection, can solve the problems of waste of raw materials, unqualified pipes, high production costs and material costs, etc., and achieve The effect of reducing labor intensity, processing difficulty and cost, and high pass rate of ultrasonic flaw detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

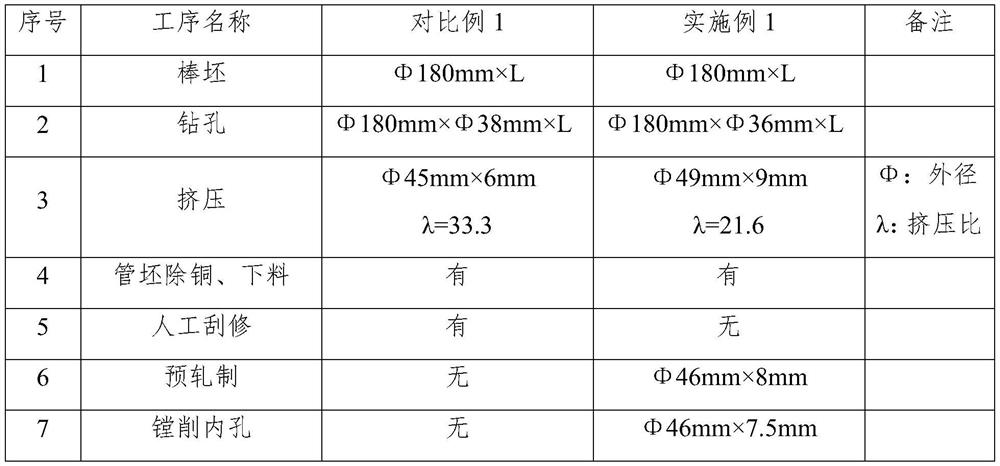

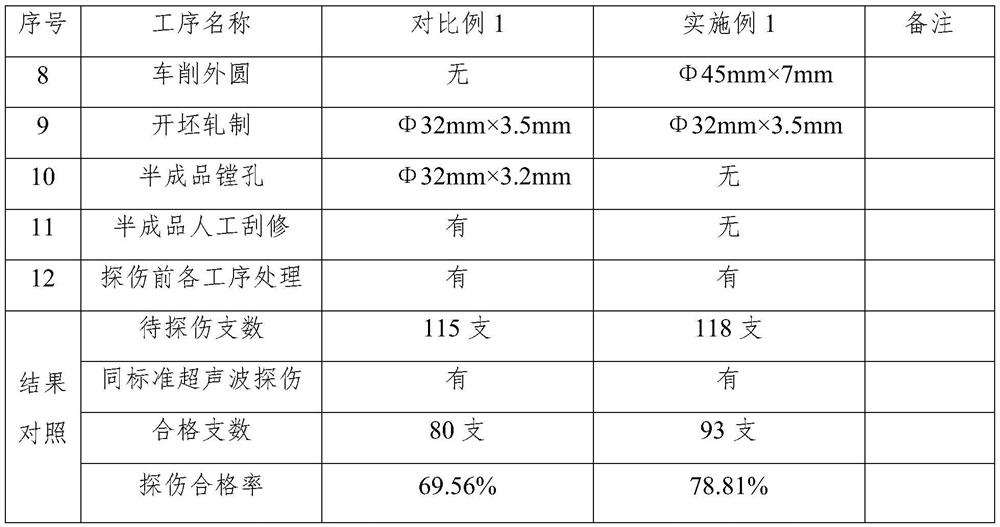

[0028] Example 1 The tube blank pre-preparation process includes tube blank pre-rolling, inner surface boring and outer surface turning, wherein the billet rolling is carried out by a two-roller tube mill, and the deformation is 62.50%, and the tube blank pre-rolling is carried out by three It is carried out in a roll tube mill, the rolling pass is one pass, and the deformation is 15.56%, and the outer surface turning is carried out by a centerless lathe.

[0029]At the same time, for the titanium alloy ultra-long seamless pipe of the same specification, in embodiment 1, the weight loss of titanium alloy produced by pre-rolling, inner surface boring and outer surface turning process is included in the billet weight in the process design. When designing the specifications of the extruded tube blank, the wall thickness removal amount of the inner surface boring and outer surface turning is included in the outer diameter, inner diameter and wall thickness of the extruded tube blan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com