End ring turning process

A turning and end ring technology, applied in the field of generator rotor end ring processing, can solve the problems of influence, traditional technology can not meet technical requirements, endanger normal operation, etc. effect of brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A copper end ring turning process, comprising the following process steps:

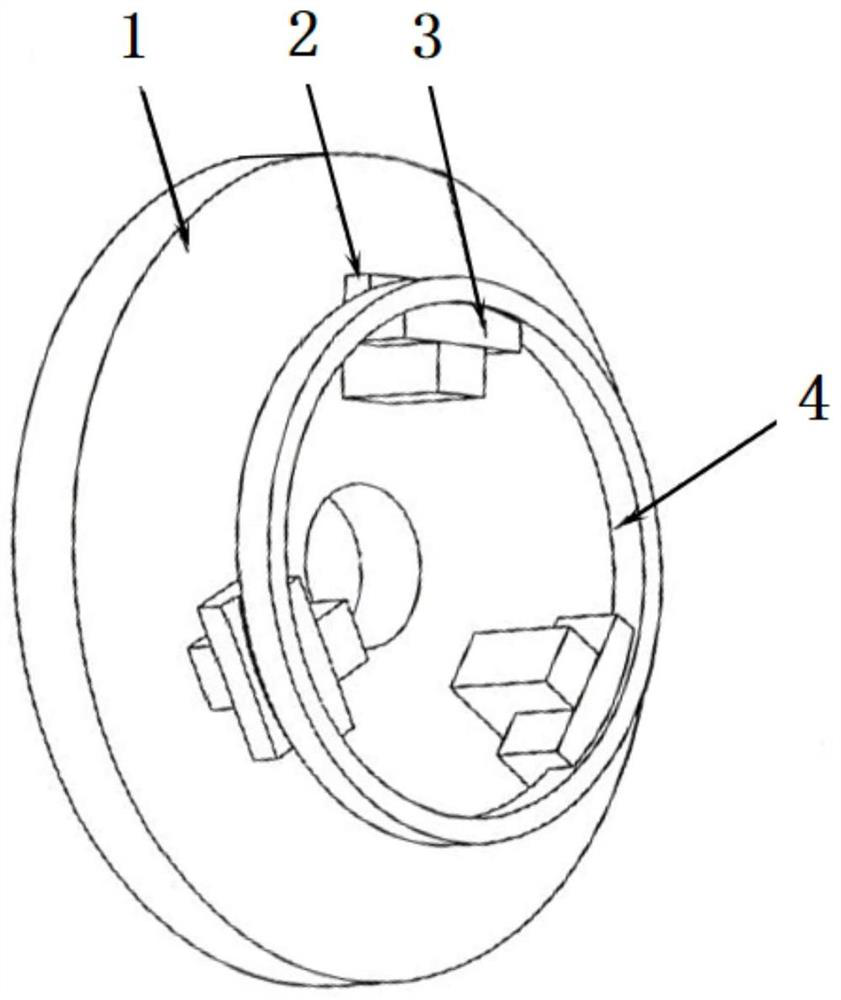

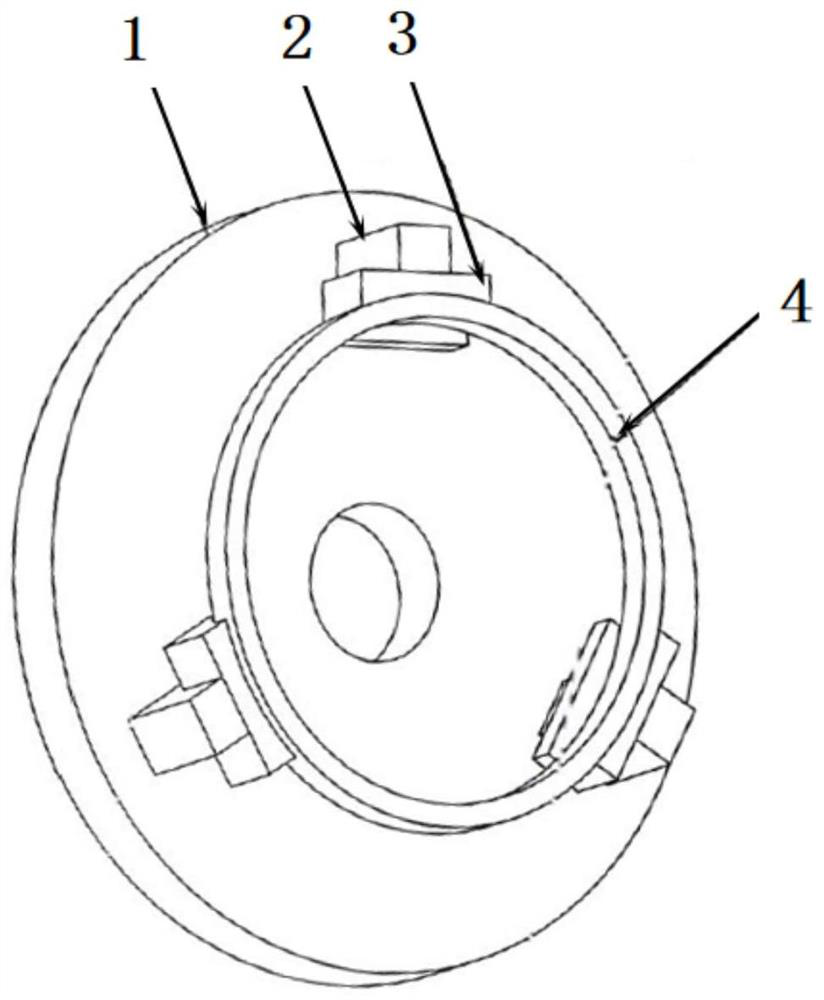

[0036] S1 rough turning first sequence: use the chuck to support the original end ring 4 blanks, use chuck 1 to support the inner hole for preliminary rough turning processing, rough turn the end face, rough turn the outer circle, and the unilateral allowance is 0.75mm, and get the rough turn first sequence rear end ring;

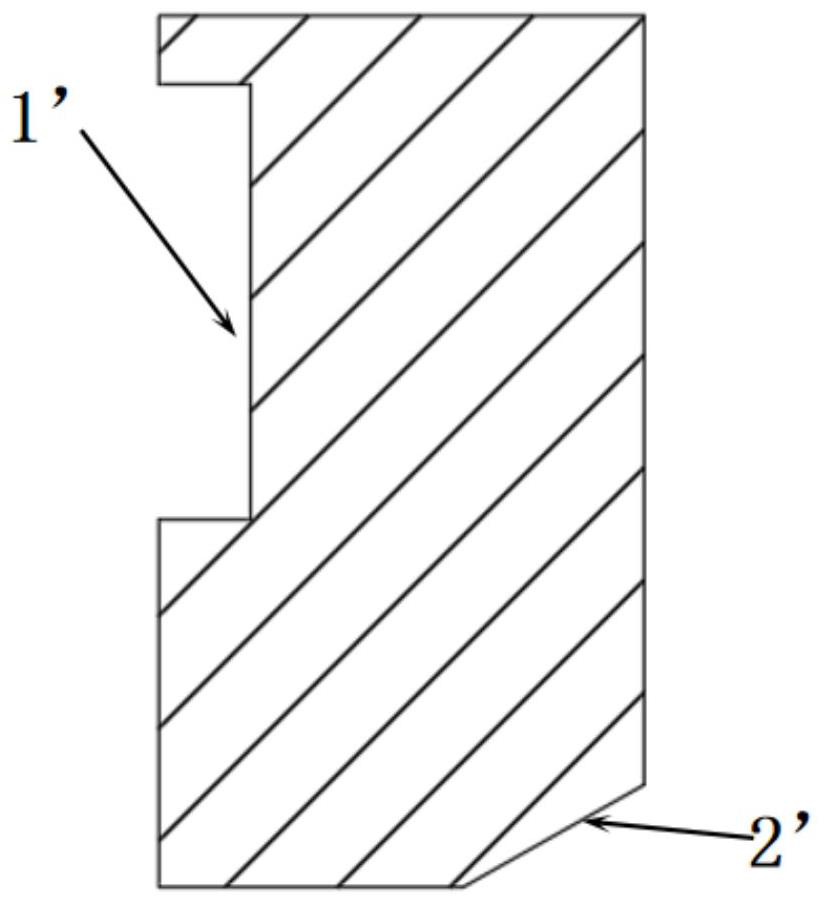

[0037] S2 rough turning second sequence: face adjustment, use chuck 1 to clamp the outer circle of the rear end ring of rough turning, rough turning end face, rough turning inner hole, unilateral allowance is 0.70mm; then start the end face groove 1', groove The inner diameter, outer diameter and the unilateral margin of the groove bottom are 0.55mm, and the thick second-order rear end ring is obtained;

[0038] S3 finish turning first step: face adjustment, use chuck 1 to support the inner hole of the rear end ring of the second step, finish turning the end face and outer ...

Embodiment 2

[0042] A process for turning a chrome-zirconium copper end ring, comprising the following process steps:

[0043] S1 rough turning first sequence: use the chuck to support the original end ring 4 blanks, use the chuck 1 support inner hole to perform preliminary rough turning processing, rough turn the end face, rough turn the outer circle, and the unilateral allowance is 0.65mm, and get the rough turn first sequence rear end ring;

[0044] S2 rough turning second sequence: face adjustment, use chuck 1 to clamp the outer circle of the rear end ring of rough turning, rough turning end face, rough turning inner hole, unilateral allowance is 0.70mm; then start the end face groove 1', groove The inner diameter, outer diameter and the unilateral margin of the groove bottom are 0.60mm, and the thick second-order rear end ring is obtained;

[0045] S3 finish turning first step: face adjustment, use chuck 1 to support the inner hole of the rear end ring of the second step, finish turn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com