Carbon-doped graphite-phase carbon nitride loaded iron-manganese denitration catalyst as well as preparation method and application thereof

A graphite-phase carbon nitride and denitrification catalyst technology, applied in the field of denitrification catalyst materials, can solve the problems of ammonia leakage, poor environmental friendliness, secondary pollution, etc., and achieve the effects of easy adsorption, improved charge transfer ability, and improved denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

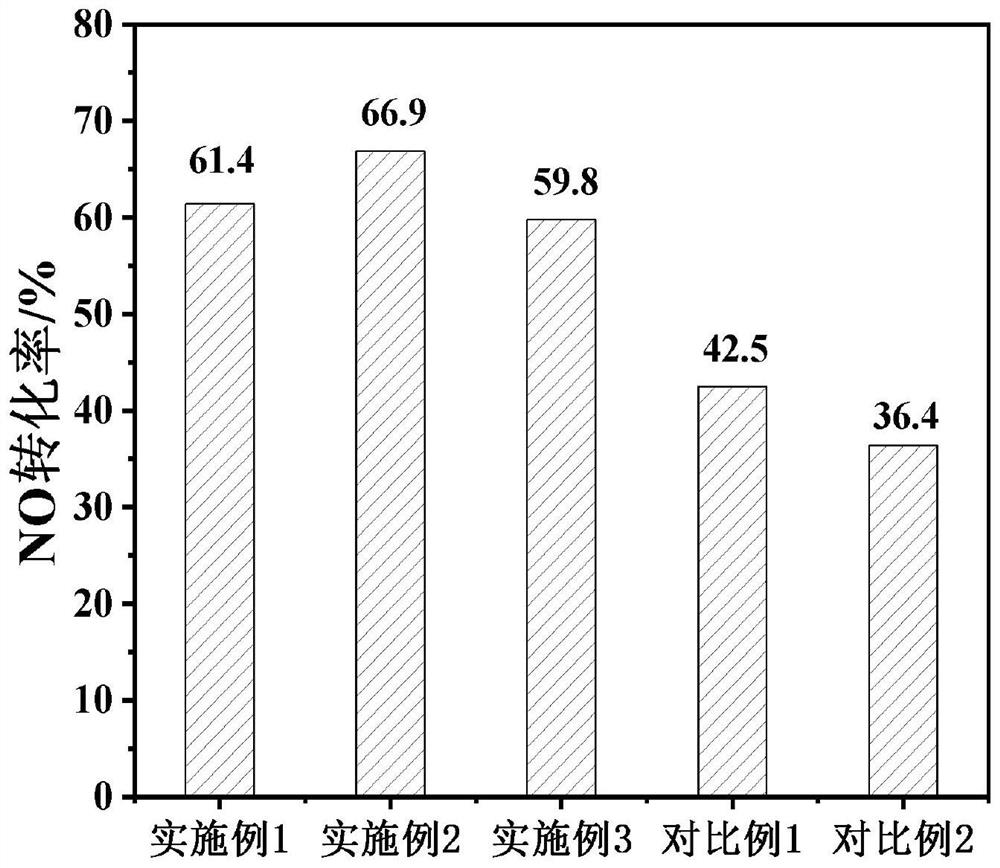

Embodiment 1

[0024] Example 1: Carbon-doped graphite phase carbon nitride-supported iron-manganese catalyst (CCN-FM)

[0025] (1) 0.075g of tannic acid is added to 15mL of deionized water to form a tannic acid solution;

[0026] (2) Put 20g of urea in a covered crucible, then add tannic acid solution and stir evenly, then heat to 400°C for 2h under air atmosphere, then heat to 500°C for 2h, you can get carbon-doped Graphite phase carbon nitride;

[0027] (3) 12g manganese acetate tetrahydrate is dissolved in 50mL deionized water, after its dissolution is completed, 10g ferric nitrate nonahydrate is added, and the graphite phase carbon nitride of 6g carbon doping is added in the mixed solution of manganese acetate and ferric nitrate, carry out Stir magnetically for 2 hours, dry at 105°C after stirring, and finally calcinate in a muffle furnace at 500°C for 2 hours (heating rate 5°C / min) to obtain a carbon-doped graphite phase carbon nitride-supported iron-manganese denitrification catalyst...

Embodiment 2

[0028] Example 2: Carbon-doped graphite phase carbon nitride-supported iron-manganese catalyst (CCN-FM)

[0029] (1) 0.15 g of tannic acid is added to 15 mL of deionized water to form a tannic acid solution;

[0030] (2) Put 20g of urea in a covered crucible, then add tannic acid solution and stir evenly, then heat to 400°C for 2h under air atmosphere, then heat to 500°C for 2h, you can get carbon-doped Graphite phase carbon nitride;

[0031] (3) 12g manganese acetate tetrahydrate is dissolved in 50mL deionized water, after its dissolution is completed, 10g ferric nitrate nonahydrate is added, and the graphite phase carbon nitride of 6g carbon doping is added in the mixed solution of manganese acetate and ferric nitrate, carry out Stir magnetically for 2 hours, dry at 105°C after stirring, and finally calcinate in a muffle furnace at 500°C for 2 hours (heating rate 5°C / min) to obtain a carbon-doped graphite phase carbon nitride-supported iron-manganese denitrification catalys...

Embodiment 3

[0032] Example 3: Carbon-doped graphite phase carbon nitride-supported iron-manganese catalyst (CCN-FM)

[0033] (1) 0.3 g of tannic acid is added to 15 mL of deionized water to form a tannic acid solution;

[0034] (2) Put 20g of urea in a covered crucible, then add tannic acid solution and stir evenly, then heat to 400°C for 2h under air atmosphere, then heat to 500°C for 2h, you can get carbon-doped Graphite phase carbon nitride;

[0035] (3) 12g manganese acetate tetrahydrate is dissolved in 50mL deionized water, after its dissolution is completed, 10g ferric nitrate nonahydrate is added, and the graphite phase carbon nitride of 6g carbon doping is added in the mixed solution of manganese acetate and ferric nitrate, carry out Stir magnetically for 2 hours, dry at 105°C after stirring, and finally calcinate in a muffle furnace at 500°C for 2 hours (heating rate 5°C / min) to obtain a carbon-doped graphite phase carbon nitride-supported iron-manganese denitrification catalyst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com