Preparation method and application of Ni-doped MIL-88A-CoMo8 composite material

A technology of composite materials and mixed solutions, applied in chemical instruments and methods, cobalt compounds, electrolytic components, etc., can solve the problems of limited reserves, limited large-scale application, high price, etc., to maintain stability, enhance charge transfer ability, The effect of reducing the resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work fall within the protection scope of the present invention.

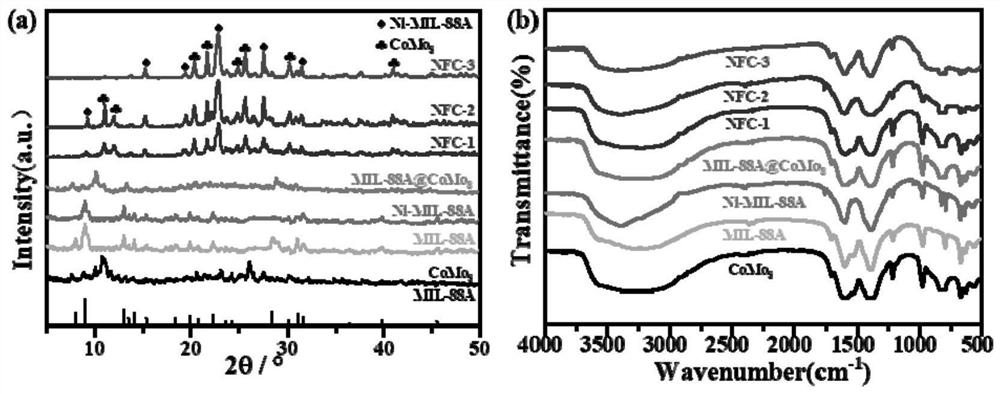

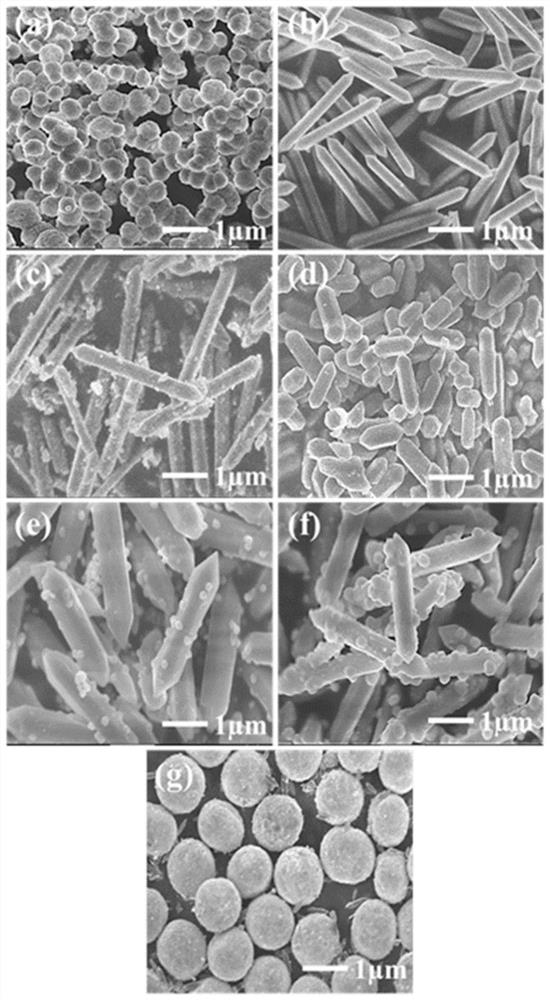

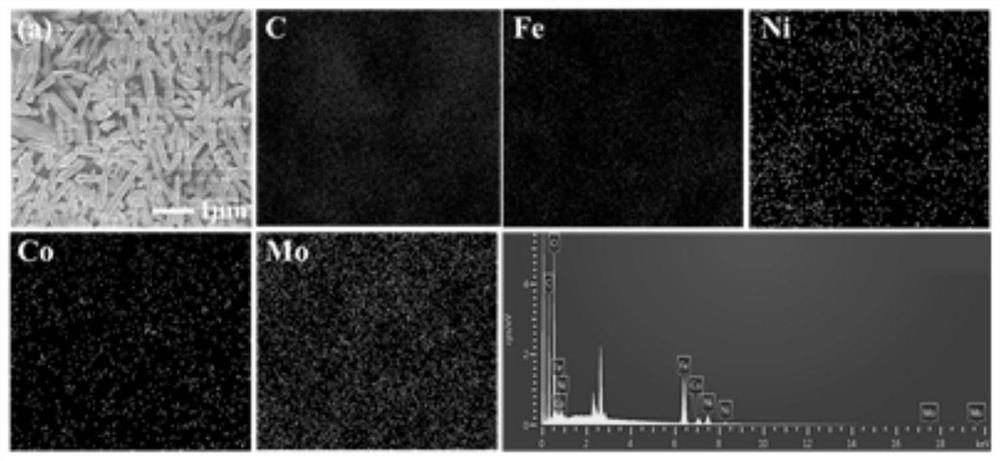

[0020] Ni-doped MIL-88A@CoMo provided by the present invention 8 The preparation method of composite material comprises the following steps:

[0021] (1) 1.2 mmol of fumaric acid was dissolved in 25 ml of deionized (DI) water, and stirred at 4000 rpm for 10 min at 70° C. to obtain solution A.

[0022] (2) 1.3mmol FeCl 3 ·9H 2 0 and 3.9 mmol Ni (NO 3 ) 2 ·6H 2 O, 0.1 or 0.2 or 0.3 mmolCoMo 8 Dissolve in 5 ml of deionized water, and stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com