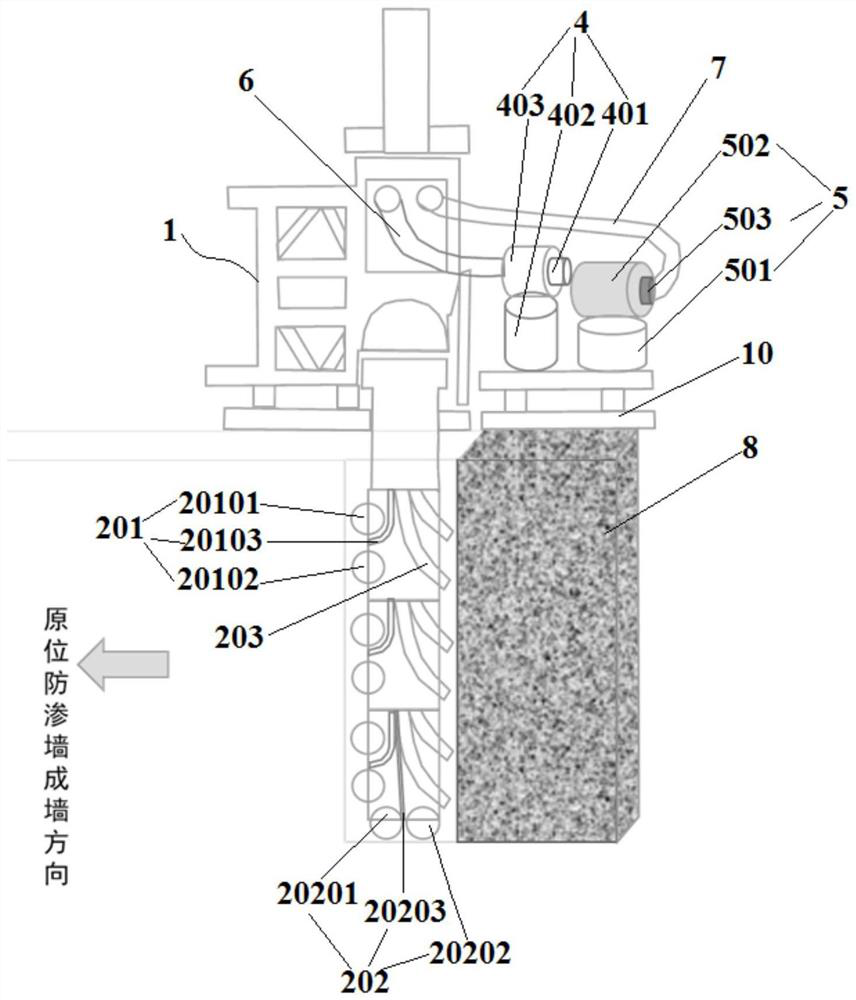

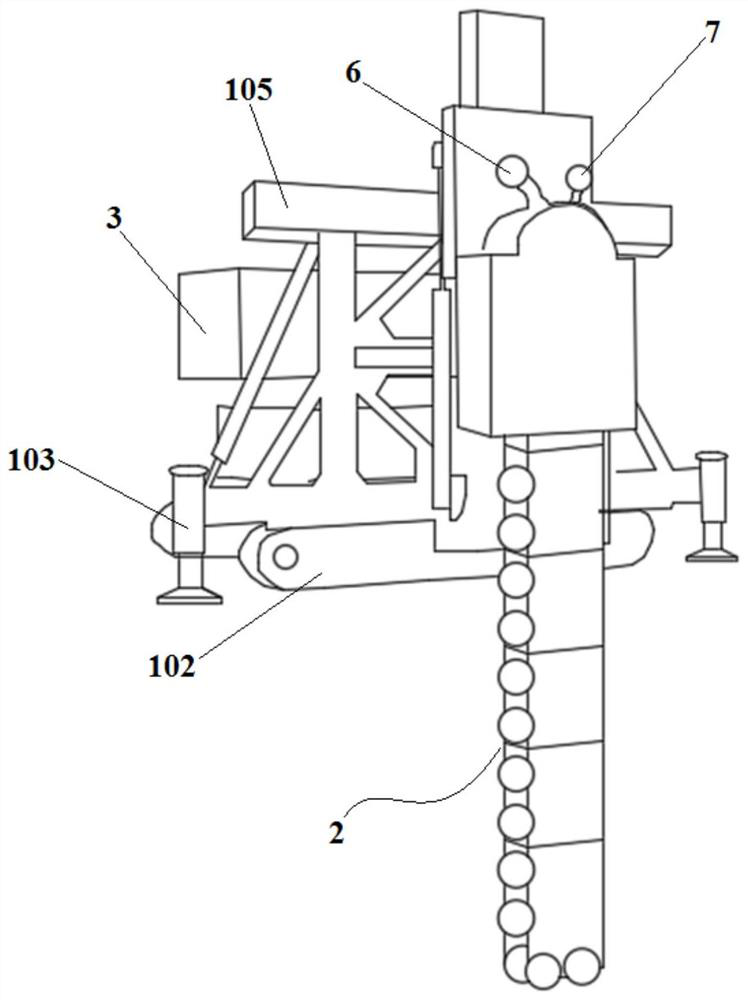

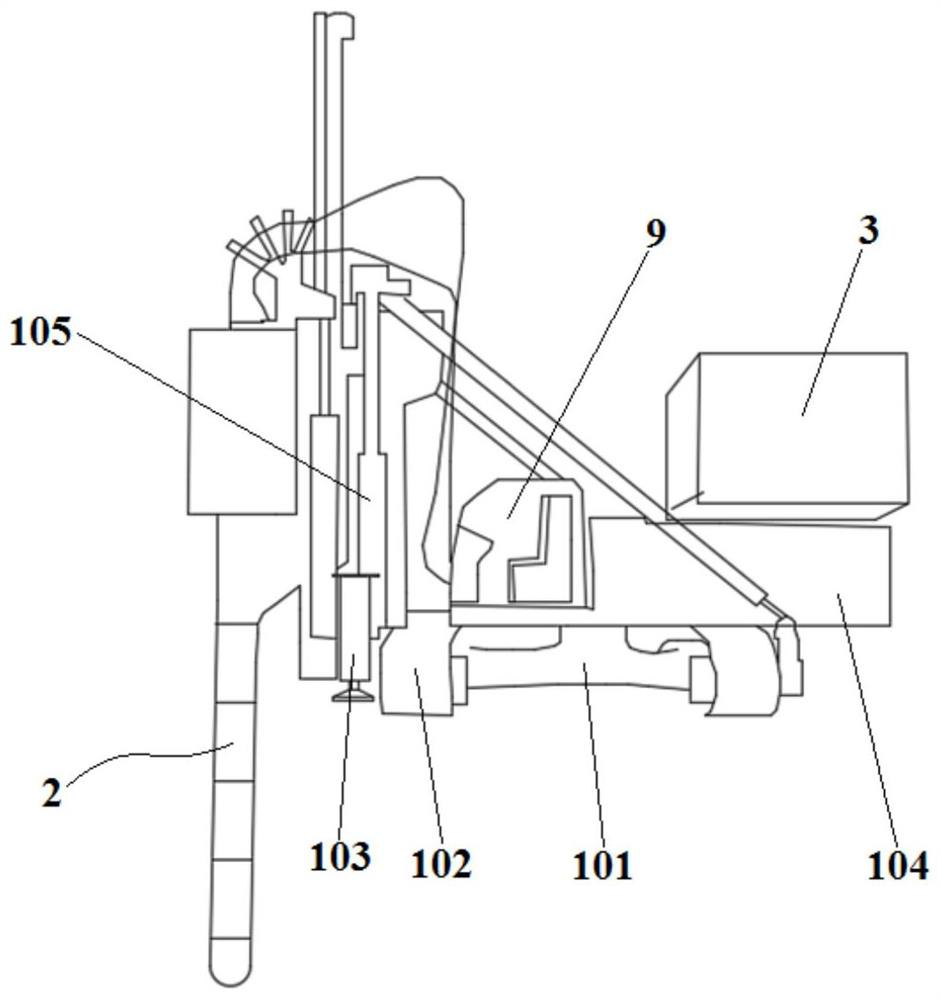

Joint-free continuous in-situ diaphragm wall construction device and curtain construction method

A jointless, anti-seepage wall technology, used in construction, sheet pile wall, infrastructure engineering, etc., can solve the problems of poor water interception efficiency, large number of water interception curtain joints, insufficient strength of curtain wall, etc., to reduce mechanical occupation. land, realize harmless utilization, and reduce the effect of leakage points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] An open-pit coal mine is covered with a sandy pebble layer on the water-rich aquifer layer. The pebble particle size is 5-150mm, the aquifer thickness is 30-50m, the permeability coefficient is 10-100m / d, and the drainage volume of the pit is tens of thousands of m 3 / d, the groundwater level drops by 40-80m. In order to protect the ecological groundwater level and groundwater resources of open-pit coal mines, cut-off curtains are used to construct water-cutting curtains to trap open-pit coal mine pits and isolate the hydraulic connections between the pits and the external strata.

[0097] Step 1: According to the engineering geology and hydrogeological characteristics of the open-pit coal mine, determine the starting point, design direction and end position of the water-cutting curtain, the thickness of the water-cutting curtain is 0.8m, and the depth of the water-cutting curtain is 50m. In the layer of mudstone, the open pit is trapped in the water cut-off curtain;

...

Embodiment 2

[0110] The lateral recharge aquifer in an underground coal mine is mainly a thick sand layer, the aquifer thickness is 80-100m, the sandstone compressive strength is 20MPa, the permeability coefficient is 3m / d, and the mine water inflow is tens of thousands of m 3 / d. In order to protect the ecological groundwater level and groundwater resources of the underground coal mine, the cut-off curtain is constructed by using the anti-seepage wall to isolate the hydraulic connection between the working face of the underground coal mine and the outer sandstone aquifer.

[0111] Step 1: According to the engineering geology and hydrogeological characteristics of underground coal mines, determine the starting position, design forward direction and end position of the water-cutting curtain, the thickness of the water-cutting curtain is 1.0m, and the depth of the water-cutting curtain is 100m. In the mudstone of the water layer, the top of the cut-off wall is located in the red clay of the ...

Embodiment 3

[0124] The strata in the area where a certain tailings reservoir is located are mainly silt, sand, and clay. The thickness of the silt and sand layers is 50-60m, and the permeability coefficient is 0.15m / d. In order to solve the problem of groundwater pollution by the seepage of the tailings reservoir and protect the surrounding ecological groundwater level and groundwater resources, the water-cutting curtain is constructed with an anti-seepage wall to isolate the hydraulic connection between the tailings reservoir and the outer silt and sand layers.

[0125] Step 1: According to the engineering geology and hydrogeological characteristics of the tailings mine site, determine the start position, design direction and end position of the water interception curtain, the thickness of the water interception curtain is 0.6m, the depth of the water interception curtain is 60m, and the bottom of the cutoff wall is located at In the mudstone of the water-resisting layer, the top of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com