Circulating electroplating equipment for machining and use method of circulating electroplating equipment

A kind of electroplating equipment and machining technology, applied in the direction of plating tank, electrolysis process, electrolysis components, etc., can solve the problems of increasing the cost of electroplating and large power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

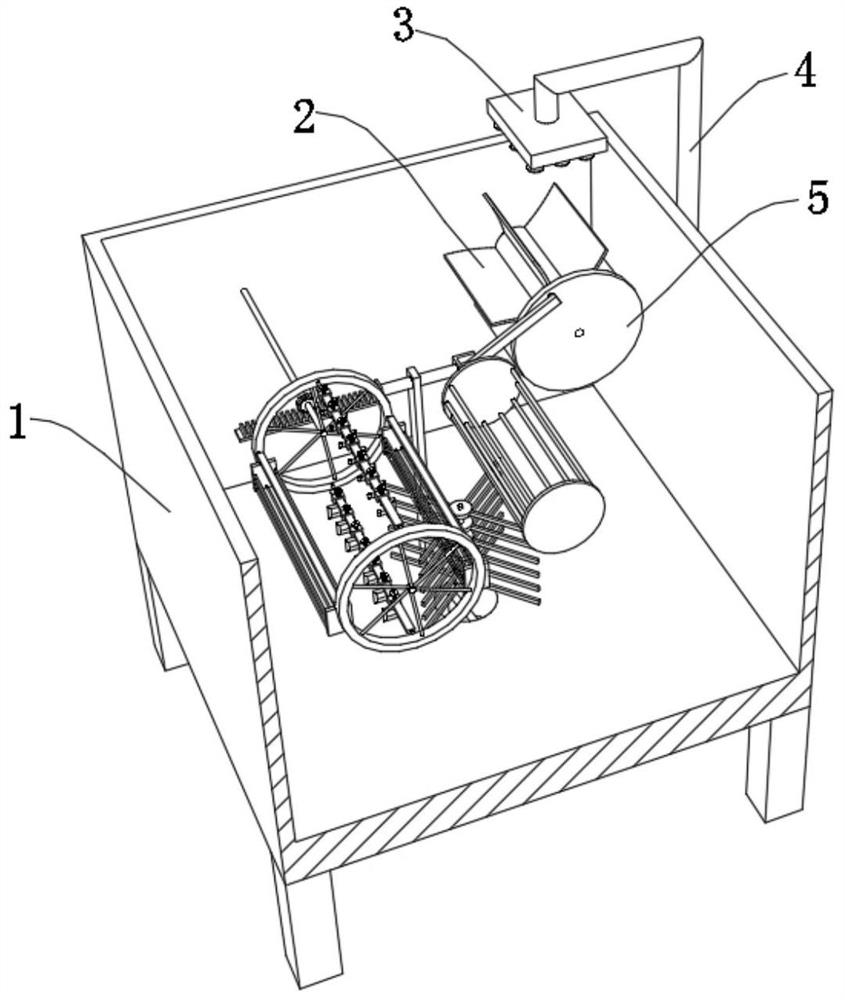

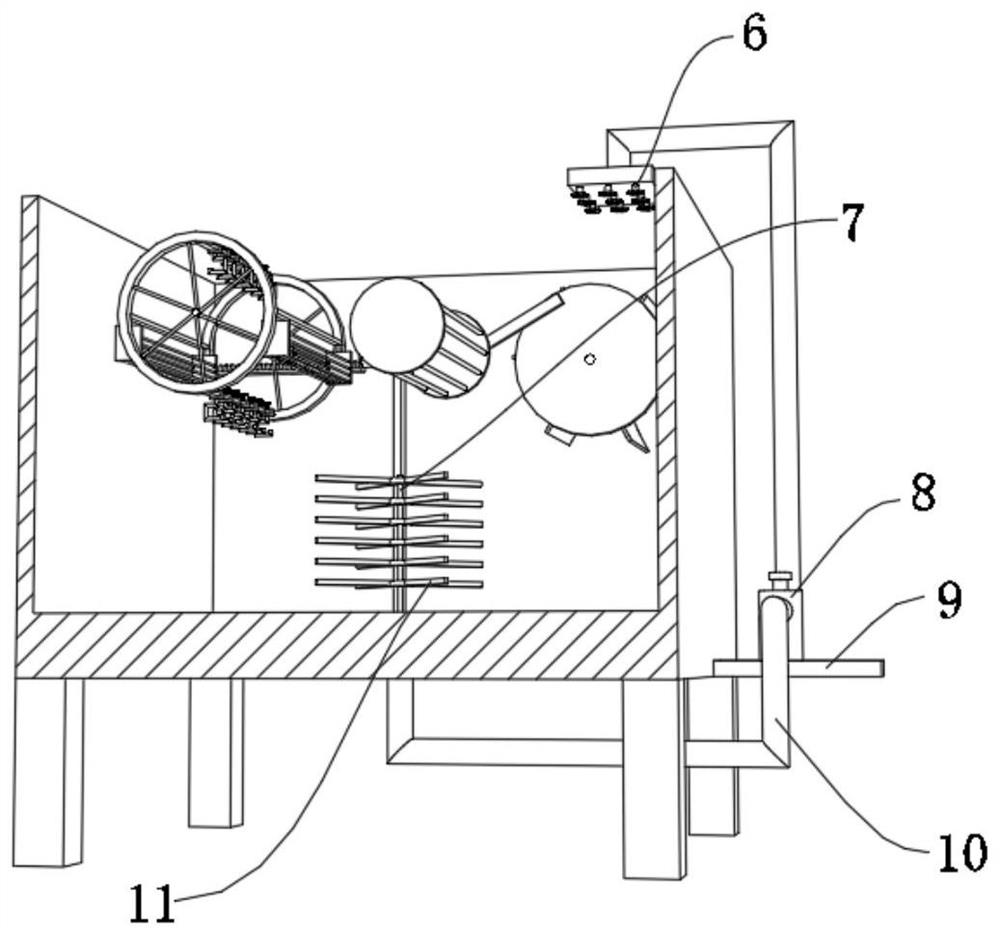

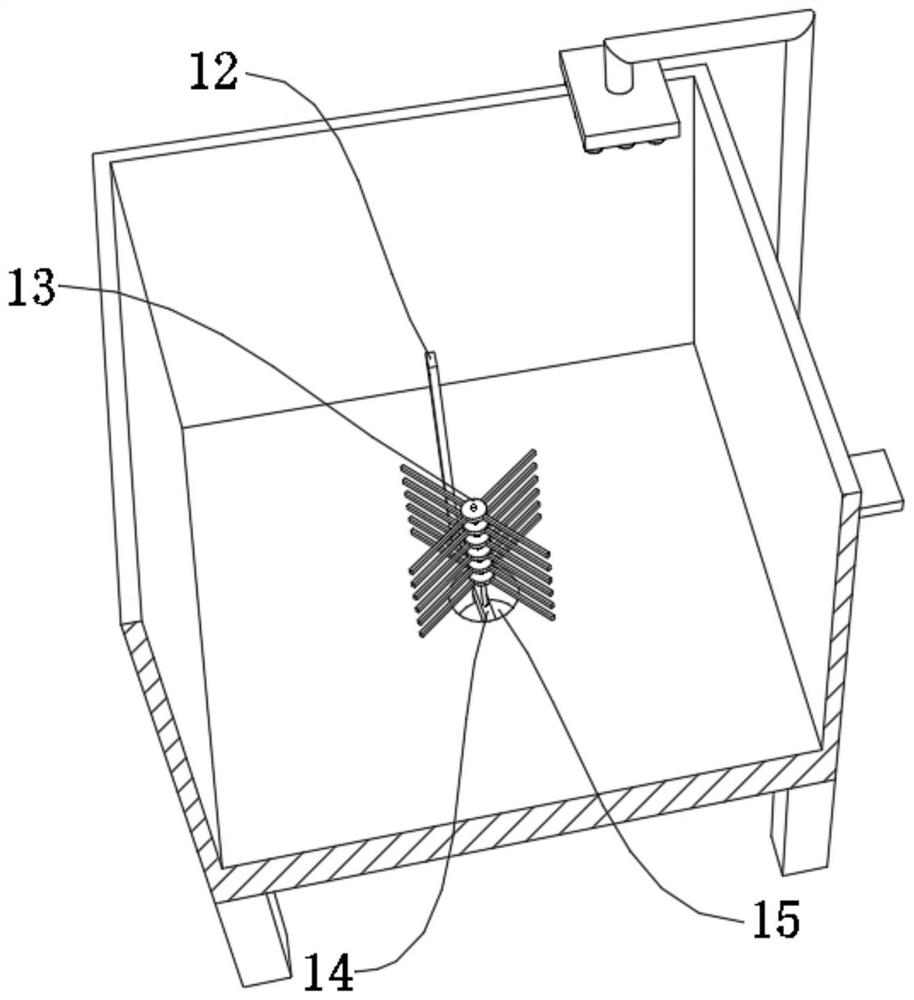

[0039] A kind of cycle electroplating equipment for mechanical processing, such as Figure 1-4As shown, it includes an electroplating box 1 and a return mechanism. The inner wall of one side of the electroplating box 1 is rotatably connected with a guide column 20, and the outer wall of the guide column 20 is fixed with more than two arc-shaped toggle plates 2 by bolts. The outer wall of one side of the guide column 20 is fixed with a rotating disk 5 by bolts, the outer wall of one side of the rotating disk 5 is rotatably connected with a rocker 21, and the outer wall of the rocker 21 is rotatably connected with a bracket 19, and the outer wall of one side of the bracket 19 is rotatably connected with a bracket 19. The sliding column 22 is fixed by bolts, the outer wall of one side of the sliding column 22 is fixed with a rack 17 by bolts, the inner wall of the bottom of the electroplating box 1 is fixed by bolts to limit the limit plate 12, and the outer wall of the sliding co...

Embodiment 2

[0044] A kind of cycle electroplating equipment for mechanical processing, such as Figure 1-3 , Figure 6 As shown, in order to electroplate the larger electroplated parts; this embodiment makes the following additions on the basis of embodiment 1: the outer wall of one side of the bracket 19 is fixed with a hollow cylinder 32 by bolts, and the inner wall of the circumference of the hollow cylinder 32 A rotating rod 33 is connected in rotation, and the outer wall of the circumference of the rotating rod 33 is welded with a universal ball 31, and the spherical outer wall of the universal ball 31 is welded with a connecting column 34, and the outer wall of one side of the connecting column 34 is fixed with a hollow frame 35 Larger electroplating parts can be placed by being provided with hollow frame 35, and hollow frame 35 can move synchronously with the horizontal movement of support 19 simultaneously, thereby can guarantee that electroplating solution can evenly act on the l...

Embodiment 3

[0048] A method for using the cycle electroplating equipment for mechanical processing described in embodiment 1, comprising the following steps:

[0049] S1: Place the electroplated parts according to the different types;

[0050] S2: Start the booster pump 8 to make the electroplating solution flow back;

[0051] S3: Use the sliding column 22 to drive the first mounting frame 16 and the second mounting frame 26 to rotate, so that the electroplating parts and the electroplating solution are fully contacted;

[0052] S4: After the electroplating is completed, the electroplating part is removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com