Polyethylene fiber reinforced ductile plastering mortar and preparation method thereof, and method for preventing assembly type internal partition wall from cracking

A polyethylene fiber, plastering mortar technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of long time, many processes, unsatisfactory anti-cracking effect, etc., and achieve the effect of inhibiting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The present invention also provides a preparation method of the polyethylene fiber reinforced ductile plastering mortar described in the above technical solution, comprising the following steps:

[0053] a) Portland cement, superfine sand, fly ash, water reducing agent and water are mixed to obtain the basic mortar;

[0054] b) mixing the basic mortar with polyethylene fibers to obtain polyethylene fiber reinforced ductile plastering mortar.

[0055] Wherein, the types and dosages of Portland cement, ultrafine sand, fly ash, water reducing agent, water and polyethylene fiber are consistent with those described in the above technical solution, and will not be repeated here.

[0056] Regarding step a): The mixing is preferably carried out in a mixer. Specifically, it is preferable to pour water into the mixer first, and then add Portland cement, ultrafine sand, fly ash, and water reducer. In the present invention, the stirring time of the mixing is not particularly limi...

Embodiment 1

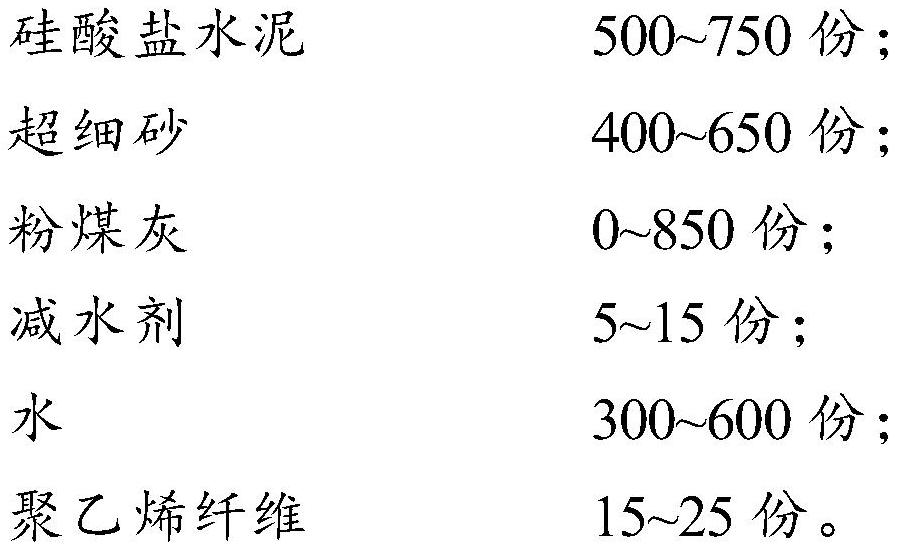

[0091] 1. Raw materials:

[0092]

[0093]

[0094] 2. Preparation:

[0095] S1. Pour water into the mixer, then add Portland cement, superfine sand, fly ash and water reducer, and stir in reverse for 3 minutes to obtain the basic mortar.

[0096] S2. Add polyethylene fibers into the mixer, and stir in the forward direction for 3 minutes to obtain plastering mortar.

Embodiment 2

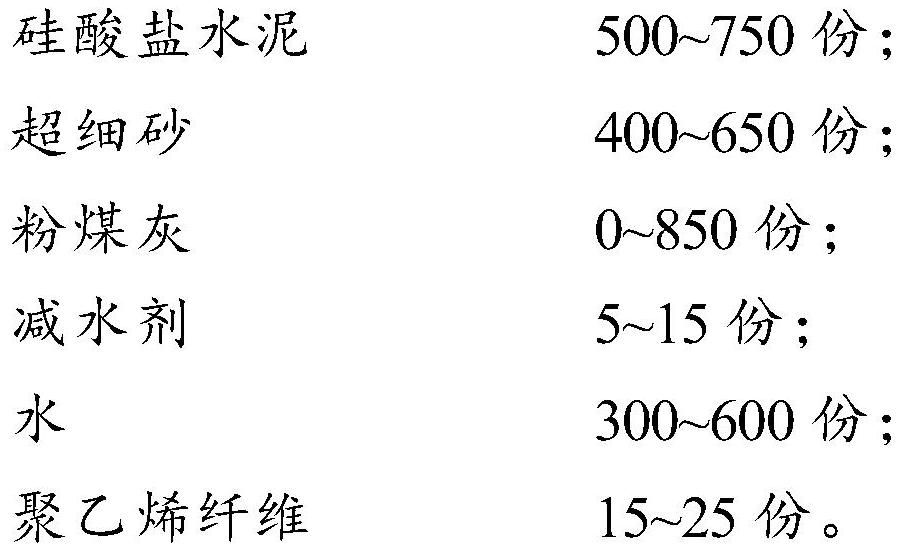

[0098] 1. Raw materials:

[0099]

[0100] 2, preparation: with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com