Pressure vessel manufacturing method and auxiliary manufacturing equipment thereof

A pressure vessel and auxiliary manufacturing technology, applied in chemical instruments and methods, manufacturing tools, metal processing equipment, etc., can solve the problems of reduced grinding efficiency, insufficient grinding transition grinding, and inability to control the degree of grinding, so as to improve grinding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

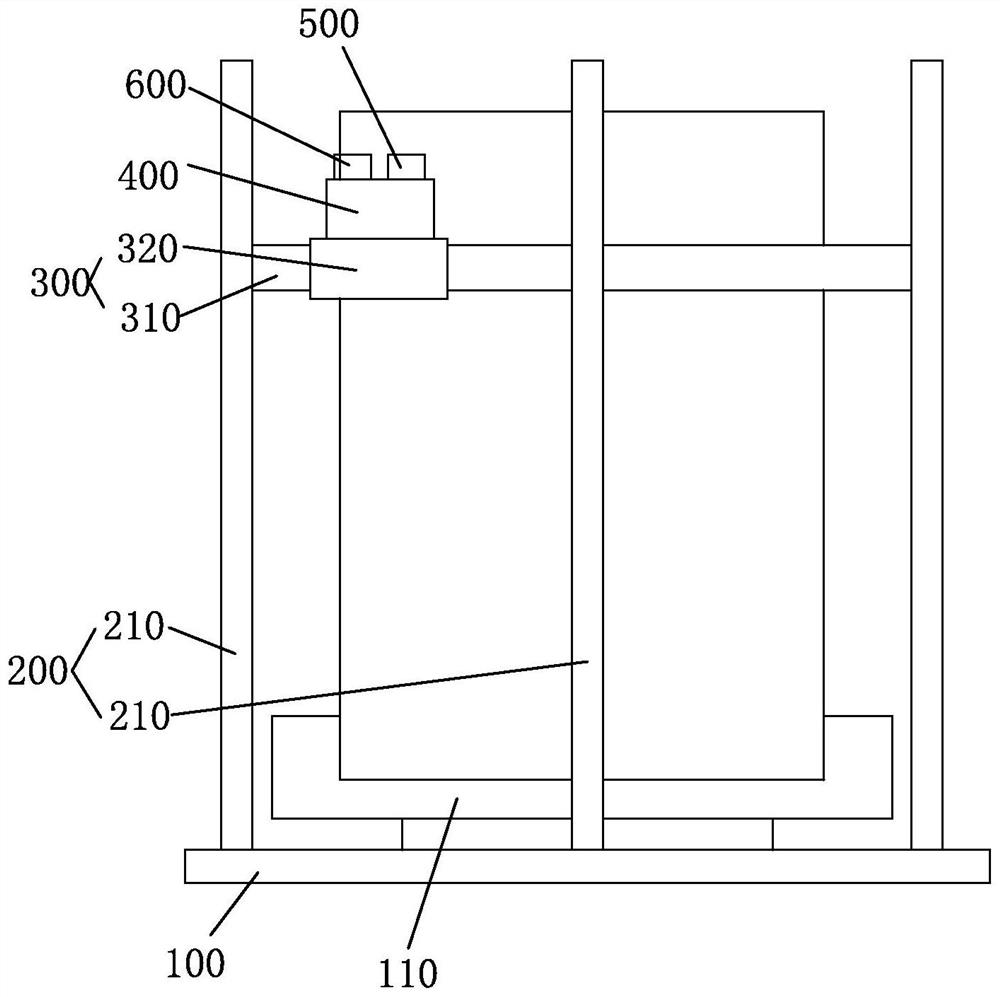

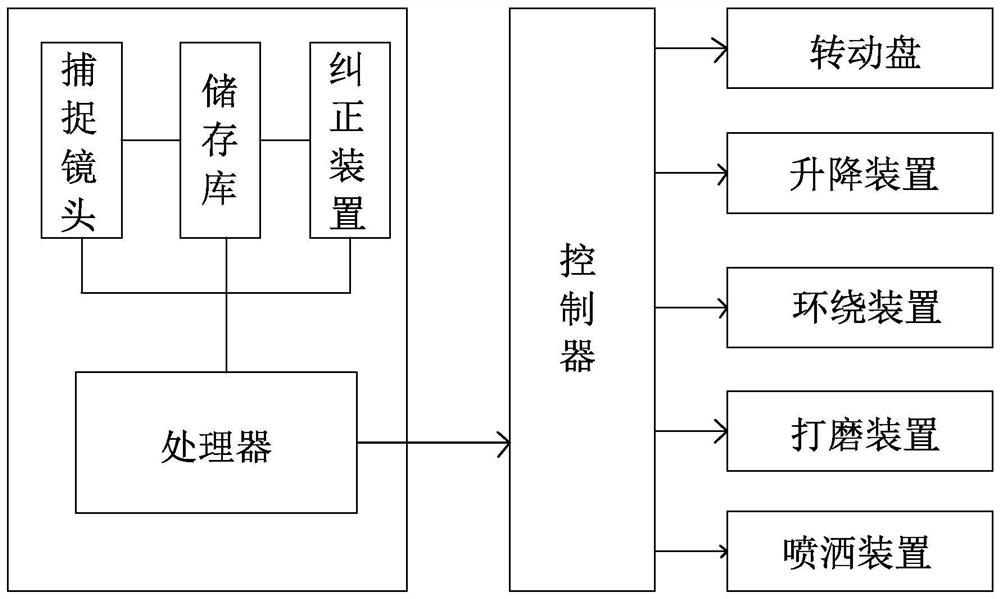

[0039] Such as figure 1 As shown, the embodiment of the present application provides an auxiliary manufacturing equipment for pressure vessels. The auxiliary manufacturing equipment includes: a base 100 for placing a pressure vessel, and a rotating disk 110 is provided on the base 100, and the pressure vessel is placed on the rotating disk 110. The rotating disk 110 drives the pressure vessel to rotate; the lifting device 200 is arranged on the base 100, and the lifting device 200 includes a plurality of vertically arranged lifting rods 210 surrounding the periphery of the pressure vessel; the surrounding device 300 is arranged on the lifting rod 210, and the surrounding device 300 includes a fixed ring 310 and a sliding block 320 arranged on the fixed ring 310. The sliding block 320 moves circularly around the pressure vessel along the fixed ring 310. The fixed ring 310 moves up and down along the pressure vessel through the lifting device 200; the grinding device 400 is set ...

Embodiment 2

[0042] The embodiment of the present application provides a pressure vessel manufacturing method and its auxiliary manufacturing equipment. In addition to the above technical features, the pressure vessel manufacturing method and its auxiliary manufacturing equipment in the embodiment of the present application also include the following technical features.

[0043] As shown in the figure, the grinding device 400 includes: a grinding base 100, which is installed on the sliding block 320; a driver 420, which is arranged on the grinding base 100, and the end of the driver 420 is provided with a grinding head 421, and the driver 420 drives the grinding head 421 to rotate, The grinding head 421 is used for grinding the pressure vessel; the protective cover 430 is arranged on the outside of the grinding head 421 to prevent the dust from splashing during grinding, and one end of the protective cover 430 is connected to the grinding base 100; the collecting device 440 is arranged on th...

Embodiment 3

[0046] The embodiment of the present application provides a pressure vessel manufacturing method and its auxiliary manufacturing equipment. In addition to the above technical features, the pressure vessel manufacturing method and its auxiliary manufacturing equipment in the embodiment of the present application also include the following technical features.

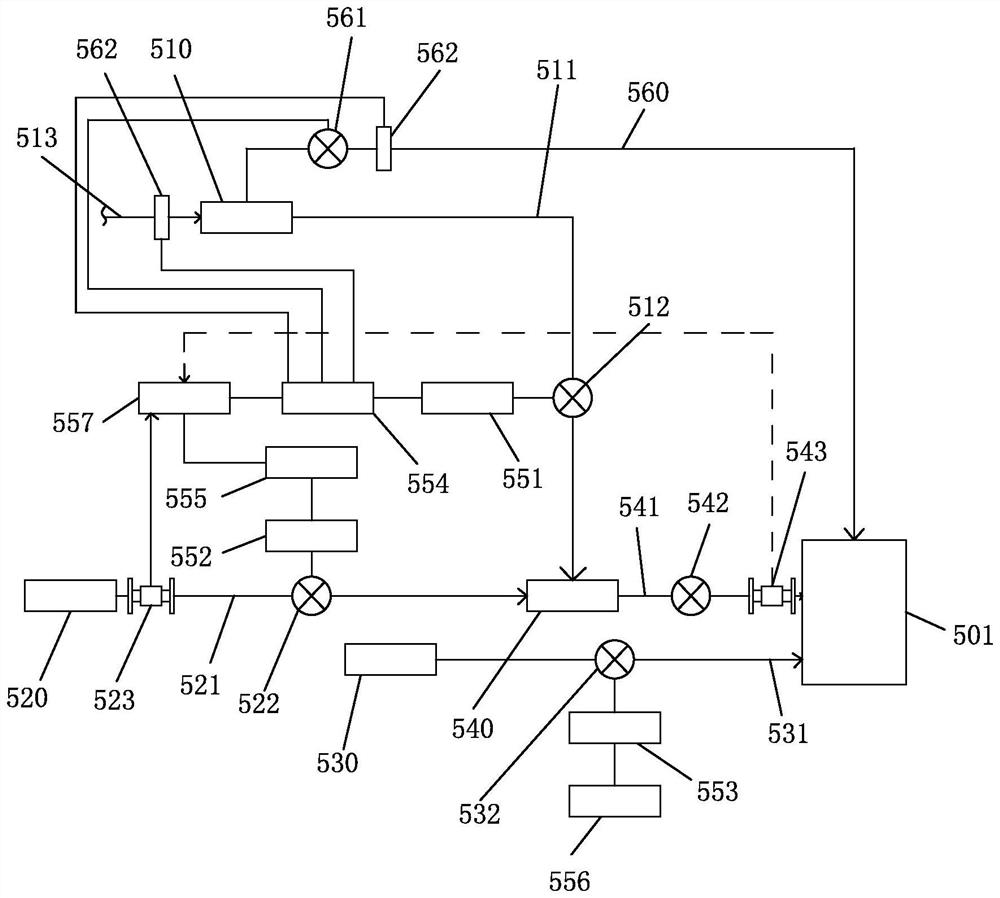

[0047] As shown in the figure, the spraying device 500 includes: a sprayer 501 disposed on the protective cover 430 for spraying liquid, one end of the sprayer 501 penetrates the protective cover 430 and extends into the protective cover 430; a first liquid storage tank 510, Placed on the ground for storing water, and the first liquid storage tank 510 is connected to the tap water pipe 513; the second liquid storage tank 520 is set on one side of the first liquid storage tank 510 for storing rust removal liquid; the third The liquid storage tank 530 is arranged on one side of the second liquid storage tank 520 for storing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com