Preparation method of composite contact

A composite contact and contact technology, which is applied in the direction of contacts, electrical components, electric switches, etc., can solve the problems of non-corrosion and anti-ablation performance, easy burning and loss of contacts, and decreased conductivity of contacts, etc., to achieve Meet the needs of industrialization, realize the effect of mass production and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] In one or more embodiments of the present invention, a method for preparing a composite contact includes the following steps:

[0023] Using the powder metallurgy process, the contact material is pre-pressed to obtain a contact pre-pressed block, the contact pre-pressed block is placed in the contact assembly mold, and the base material is filled in the contact assembly mold, after pre-pressing The contact pre-compaction block is obtained, the contact pre-compaction block is pressed and sintered in powder metallurgy equipment, the contact material of the contact pre-compact block is sintered into a contact, the base material is sintered into a base material, and the The contact assembly of the contact and the base material is assembled to form a composite contact; the contact material includes copper-chromium alloy powder and strengthening particles, and the strengthening particles are Cr 2 Nb、Al 2 o 3 As a kind of WCu powder, copper-chromium-zirconium alloy powder is...

Embodiment 1

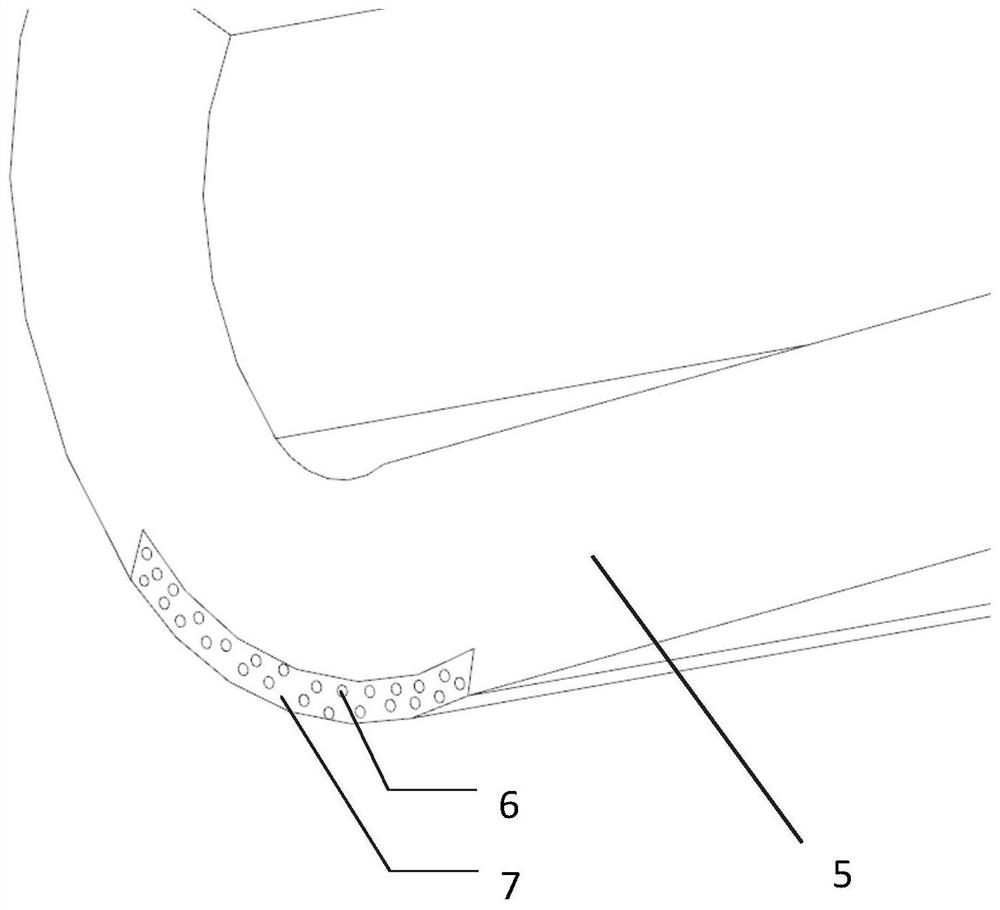

[0043] The structure of the composite contact made in this embodiment is as follows Figure 1~4 shown. Specific steps are as follows:

[0044] 1) Copper-chromium alloy powder with a particle size of 3 μm and 0.2 μm Cr 2 Nb powder mixed with Cr 2 The mass percent content of Nb powder is 3%. The mixed powder is placed in a ball mill for ball milling and mixing, and then pre-pressed at 500 MPa to obtain a contact pre-pressed block;

[0045] 2) Place the above-mentioned pre-pressed contact pre-pressed block in a contact assembly mold with a pressing function, fill it with copper-chromium-zirconium alloy powder and press it, and place the contact assembly mold in a powder metallurgy vacuum furnace. Sintering at 5MPa and 900°C for 30min, the contact material is sintered into contact 1, the base material is sintered into base material, the moving contact assembly 21 and the static contact assembly 31 are prepared, and assembled to form a composite contact . The contact 1 includ...

Embodiment 2

[0050] The preparation method of this embodiment and embodiment 1 is basically the same, the difference is: Cr 2 The mass percent content of Nb powder is 9%. Specific steps are as follows:

[0051] 1) Copper-chromium alloy powder with a particle size of 15 μm and 10 μm Cr 2 Nb powder mixed with Cr 2 The mass percent content of Nb powder is 9%. The mixed powder is placed in a ball mill for ball milling and mixed, and then pre-pressed at 350MPa to obtain a contact pre-pressed block;

[0052] 2) Place the above-mentioned pre-pressed contact pre-pressed block in a contact assembly mold with a pressing function, fill it with copper-chromium-zirconium alloy powder and press it, and place the contact assembly mold in a powder metallurgy vacuum furnace. Sintering at 3.5MPa and 900°C for 30min, the contact material is sintered into contact 1, the base material is sintered into base material, the moving contact assembly 21 and the static contact assembly 31 are prepared, and assembl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com