Auxiliary transportation robot positioning method and system in dynamic complex mine environment

A robot positioning and auxiliary transportation technology, which is applied in the direction of instruments, earthwork drilling, wellbore/well components, etc., can solve the problems of measurement loss, high cost, and affecting positioning accuracy, so as to reduce positioning error and low positioning cost , The effect of high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

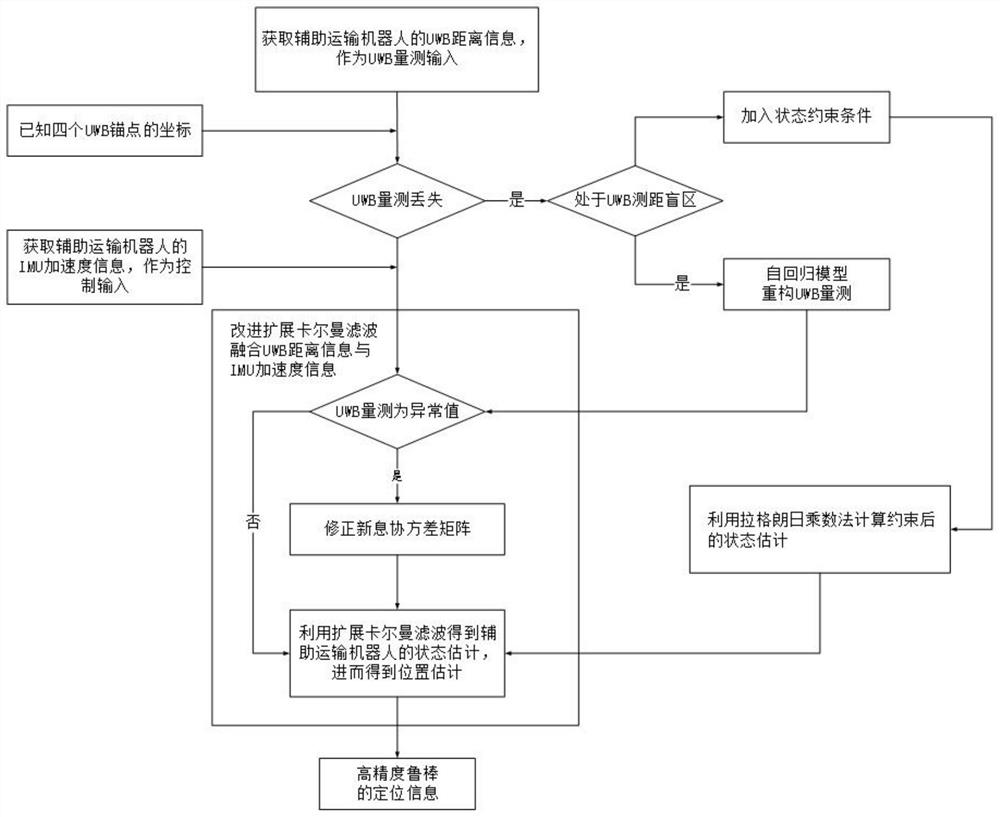

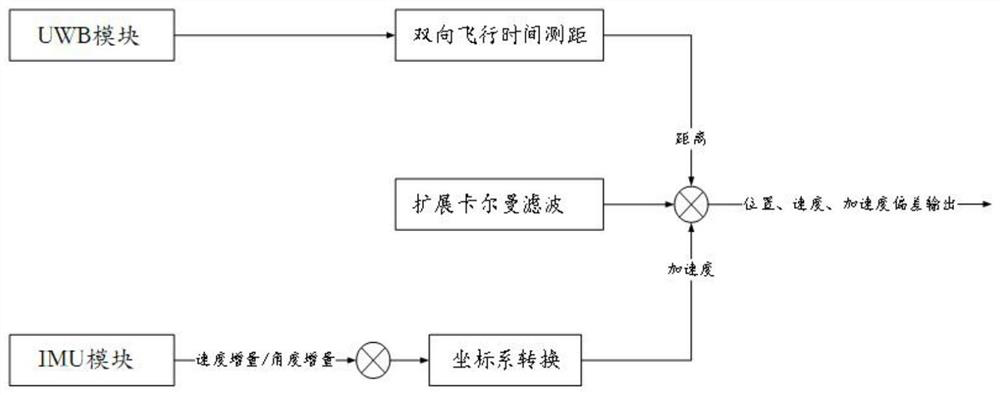

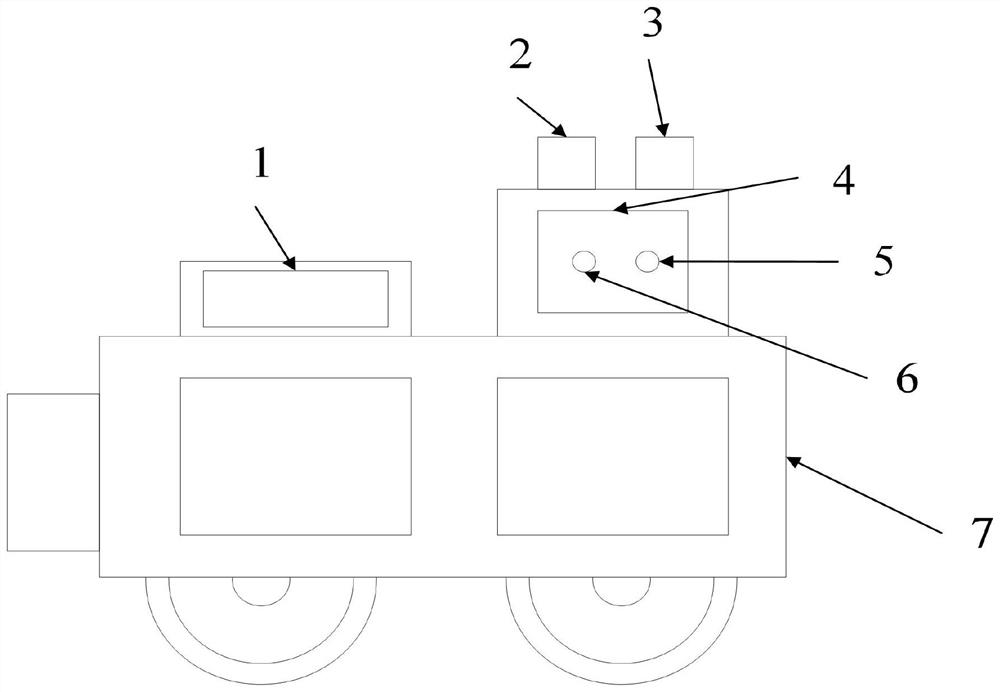

[0033] Such as figure 1 and figure 2 As shown in the present invention, a high-precision robust positioning method for an auxiliary transport robot in a strong interference mine environment, first measures the distance from the auxiliary transport robot 7 to the UWB anchor point (the coordinates of the UWB anchor point are known), and then compares the distance value with The IMU acceleration information provided by the IMU is fused using the extended Kalman filter principle to obtain high-precision and robust auxiliary transport robot 7 position information, including the following steps:

[0034] 1) Obtain the UWB distance information between the auxiliary transportation robot 7 and the UWB anchor point with known coordinates, and the IMU acceleration information of the auxiliary transportation robot 7; use the UWB distance information as the UWB measurement input, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com