Metal-organic framework material mil-125 and its preparation method and application

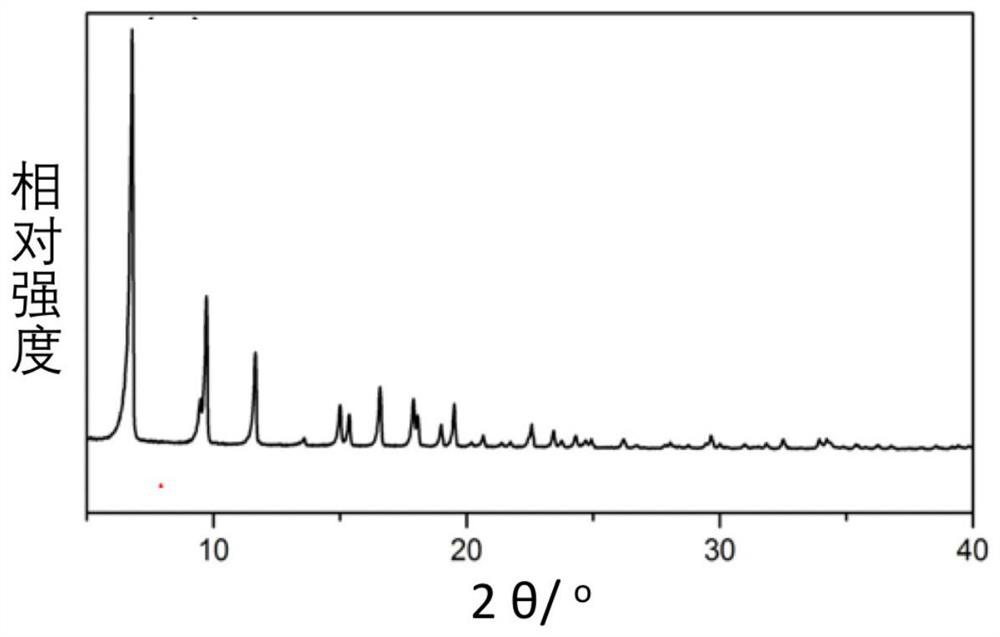

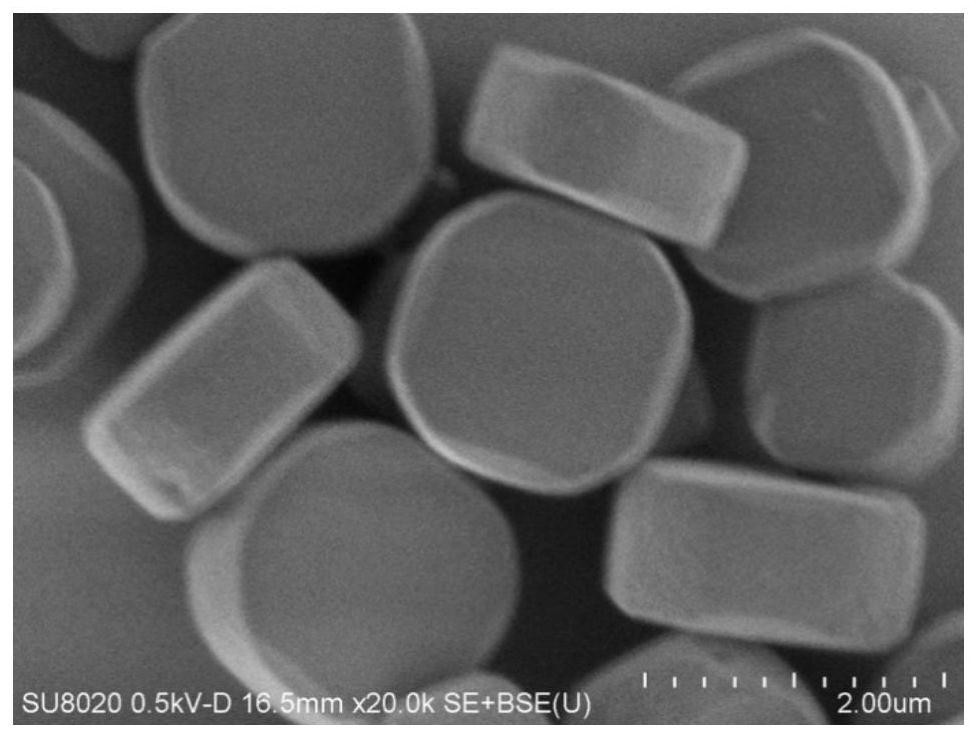

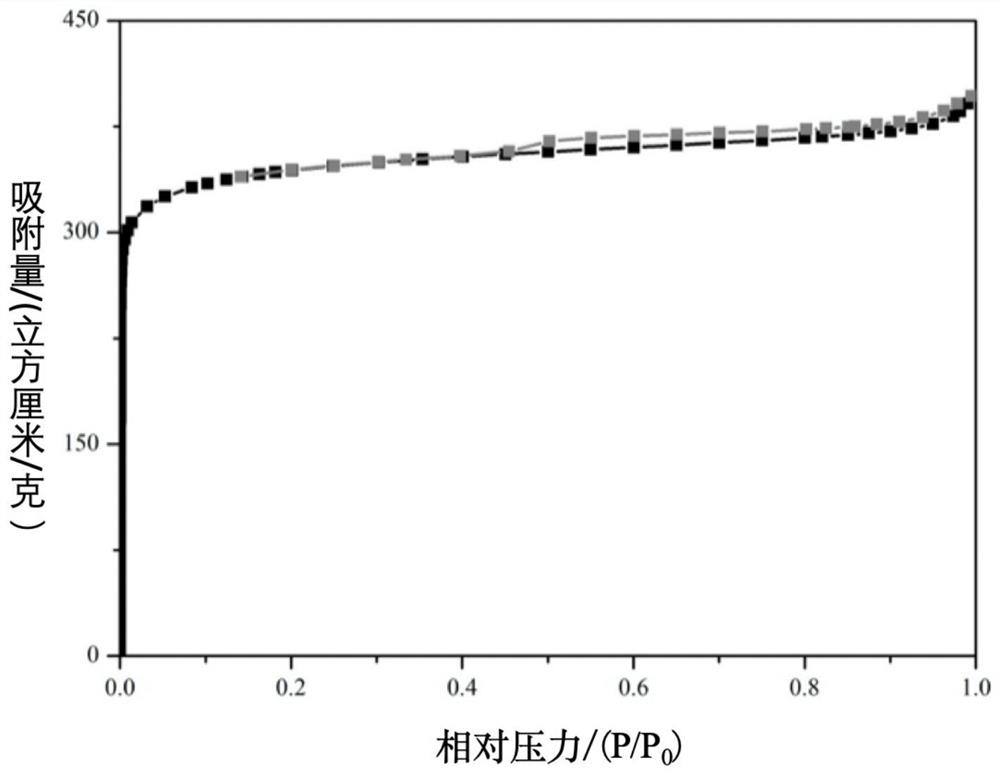

A MIL-125, metal-organic framework technology, applied in the direction of organic chemistry, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of affecting the industrial scale-up process of the application of metal-organic framework materials MIL-125 , It is difficult to control the hydrolysis rate and other issues, to achieve uniform size, prevent precipitation, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0136] The specific batching process is as follows: add 5g of tetraethyl titanate and 10g of polyethylene glycol 200 into a three-necked flask and mix evenly, carry out a transesterification reaction under stirring, connect a distillation device, pass nitrogen protection, heat up to 175 ° C, and react Time 5 hours, the conversion rate of the transesterification reaction is 75%, connect the water pump to carry out vacuum distillation to make the transesterification reaction more complete, control the vacuum degree of the system at 3KPa, the reaction temperature is 200 ℃, the reaction time is 1 hour, the transesterification reaction The conversion rate was 92%, and the titanium polyethylene glycol ester polymer was obtained. 5 g of the obtained titanium polyethylene glycol ester polymer, 5 g of terephthalic acid, 18 ml of dimethylformamide, and 2 ml of methanol were stirred at room temperature for 2 hours, and then transferred to a stainless steel autoclave. The autoclave was se...

Embodiment 2

[0138] The specific batching process is as follows: add 5g of tetraethyl titanate and 3.13g of ethylene glycol into the three-necked flask and mix evenly, carry out the transesterification reaction under stirring, connect the distillation device, pass nitrogen protection, heat up to 100 ℃, the reaction time After 5 hours, the conversion rate of the transesterification reaction was 70%. The water pump was connected to carry out vacuum distillation to make the transesterification reaction more complete. The vacuum degree of the control system was 3KPa, the reaction temperature was 170°C, and the reaction time was 1 hour. The ratio is 90%, and the titanium glycol ester polymer is obtained. 3 g of the obtained titanium glycol ester polymer, 2 g of terephthalic acid, 9 ml of dimethylformamide, and 1.2 ml of methanol were stirred at room temperature for 2 hours, and then transferred to a stainless steel autoclave. The autoclave was sealed and put into an oven that has been raised to...

Embodiment 3

[0140] The specific batching process is as follows: add 5g of tetrabutyl titanate and 11.35g of terephthalic alcohol into a three-necked flask and mix evenly, carry out a transesterification reaction under stirring, connect a distillation device, pass nitrogen protection, heat up to 160 ° C, and react Time 5 hours, the conversion rate of the transesterification reaction is 80%, connect the water pump to carry out vacuum distillation to make the transesterification reaction more complete, control the vacuum degree of the system at 3KPa, the reaction temperature is 230 ℃, the reaction time is 1 hour, the transesterification reaction The conversion rate was 95%, and the titanium terephthalate polymer was obtained. 4 g of the obtained titanium terephthalate polymer, 6.2 g of terephthalic acid, 20 ml of dimethylformamide, and 2.3 ml of methanol were stirred at room temperature for 2 hours, and then transferred to a stainless steel autoclave. The autoclave was sealed and put into an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com