Selenium-rich microbial agent and preparation method thereof

A technology of selenium-enriched microorganisms and compound microbial agents, which is applied in fertilizer mixtures, organic fertilizers, layered/coated fertilizers, etc., can solve problems such as poor absorption efficiency of inorganic selenium, improve initial reproductive performance, and improve binding effects , Improve the effect of the rhizosphere ecosystem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

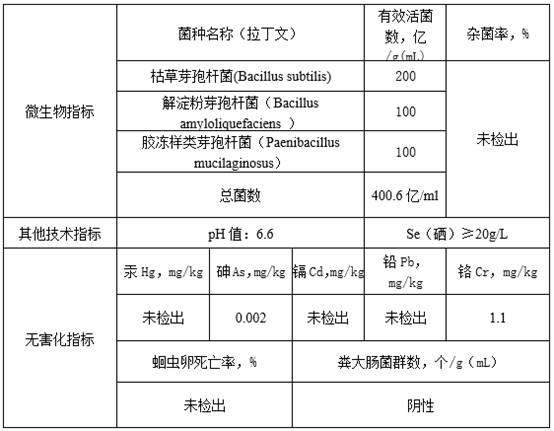

Image

Examples

preparation example 1

[0051] A MOF-based hydrogel matrix:

[0052] (1) Add 1.5kg of cellulose hydrogel and 50kg of 0.1mol / L sodium selenite solution to 100kg of cetyltrimethylammonium bromide, stir and mix and ultrasonically disperse at 200W to collect the dispersion , and then add 10 kg of ascorbic acid aqueous solution to the dispersion liquid, heat up to 55 ° C, add 3 kg of 0.1 mol / L sodium hydroxide solution, stir and mix, wash with deionized water until the washing liquid is neutral, and prepare a gel liquid ;

[0053] (2) Add 1kg of gel solution and 12kg of absolute ethanol to 20kg of N,N-dimethylformamide, stir and mix and ultrasonically disperse at 200W, collect the dispersion mixture and add 0.5kg of zinc nitrate and 0.2kg of Phthalic acid, after heating and reacting at 120°C, let it stand and cool to room temperature, wash it with deionized water, and dry it until the mass fraction of sodium selenite is 1%, then the MOF-based hydrogel matrix 1 can be prepared .

preparation example 2

[0055] A MOF-based hydrogel matrix:

[0056] (1) Add 1.5kg of cellulose hydrogel and 50kg of 0.1mol / L sodium selenite solution to 100kg of cetyltrimethylammonium bromide, stir and mix and ultrasonically disperse at 200W to collect the dispersion , and then add 10 kg of ascorbic acid aqueous solution to the dispersion liquid, heat up to 55 ° C, add 3 kg of 0.1 mol / L sodium hydroxide solution, stir and mix, wash with deionized water until the washing liquid is neutral, and prepare a gel liquid ;

[0057] (2) Add 1kg of gel solution and 12kg of absolute ethanol to 20kg of N,N-dimethylformamide, stir and mix and ultrasonically disperse at 200W, collect the dispersion mixture and add 0.5kg of zinc nitrate and 0.2kg of Phthalic acid, after heating and reacting at 120°C, let it stand and cool to room temperature, wash it with deionized water, and then dry it until the mass fraction of sodium selenite is 10%, then the MOF-based hydrogel matrix 1 can be prepared .

preparation example 3

[0059] A MOF-based hydrogel matrix:

[0060] (1) Add 1.5kg of cellulose hydrogel and 50kg of 0.1mol / L sodium selenite solution to 100kg of cetyltrimethylammonium bromide, stir and mix and ultrasonically disperse at 200W to collect the dispersion , and then add 10 kg of ascorbic acid aqueous solution to the dispersion liquid, heat up to 55 ° C, add 3 kg of 0.1 mol / L sodium hydroxide solution, stir and mix, wash with deionized water until the washing liquid is neutral, and prepare a gel liquid ;

[0061] (2) Add 1kg of gel solution and 12kg of absolute ethanol to 20kg of N,N-dimethylformamide, stir and mix and ultrasonically disperse at 200W, collect the dispersion mixture and add 0.5kg of zinc nitrate and 0.2kg of Phthalic acid, after heating and reacting at 120°C, let it stand and cool to room temperature, wash it with deionized water, and then dry it until the mass fraction of sodium selenite is 20%, then the MOF-based hydrogel matrix 1 can be prepared .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com