Lightweight multidirectional buffer energy-absorbing structure of stainless steel ultra-thin strip and preparation method of lightweight multidirectional buffer energy-absorbing structure

An energy-absorbing structure, stainless steel belt technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of weak impact load capacity, insufficient mechanical properties of honeycomb core preparation materials, etc., and achieve mechanical properties and service temperature. The effect of improvement, low manufacturing cost, and strong designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific embodiment of the present invention will be described in further detail below in conjunction with accompanying drawing:

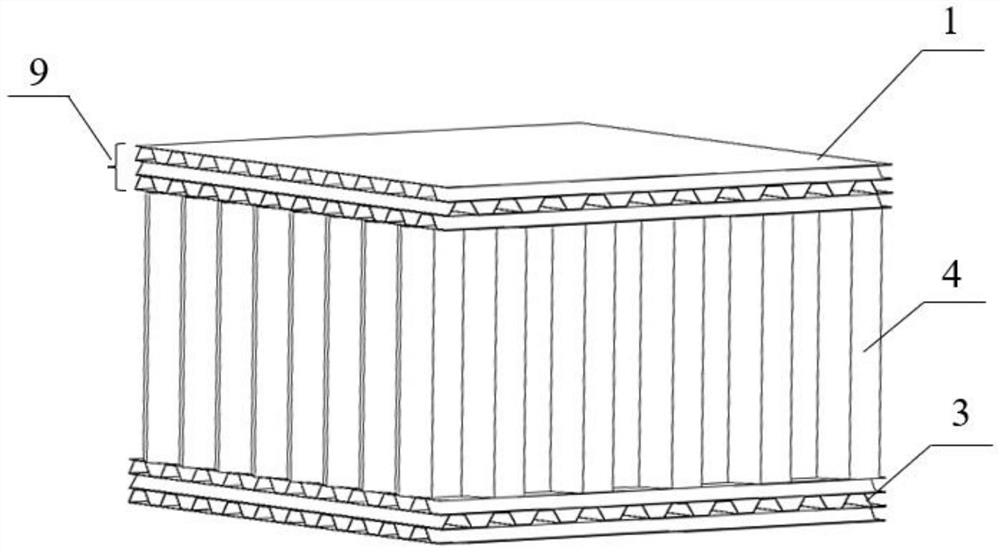

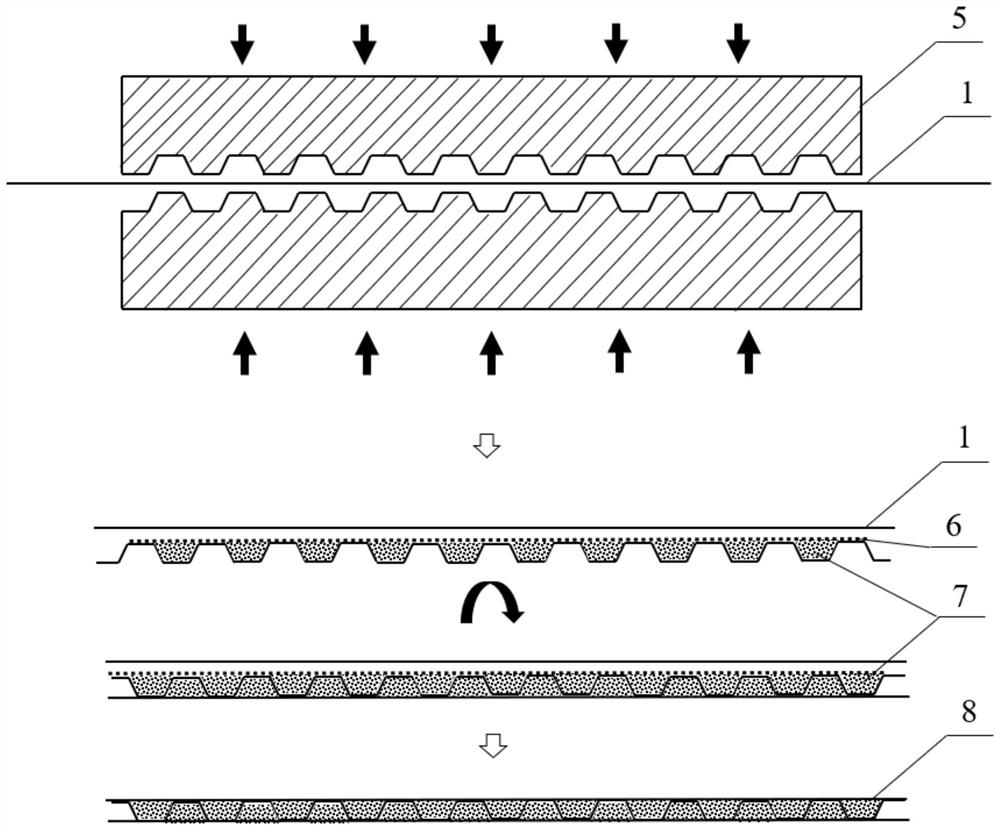

[0043] Such as Figure 1-Figure 4 As shown, a lightweight multi-directional buffer energy-absorbing structure of a stainless steel ultra-thin strip includes a honeycomb sandwich structure 4, and the upper surface and the lower surface of the honeycomb sandwich structure 4 are provided with a panel structure 9, and the panel structure 9 It includes a plurality of single-layer corrugated boards 8, and the arrangement directions of the corrugated groove layers 3 in the upper and lower two adjacent single-layer corrugated boards 8 are perpendicular to each other; wherein the single-layer corrugated boards 8 are from top to bottom It includes an upper surface layer, a corrugated groove layer 3 and a lower surface layer, the corrugated groove layer 3 is filled with fly ash floating beads 7; the cross-sectional shape of the corrugated groove la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com