Blade composite surface strengthening method

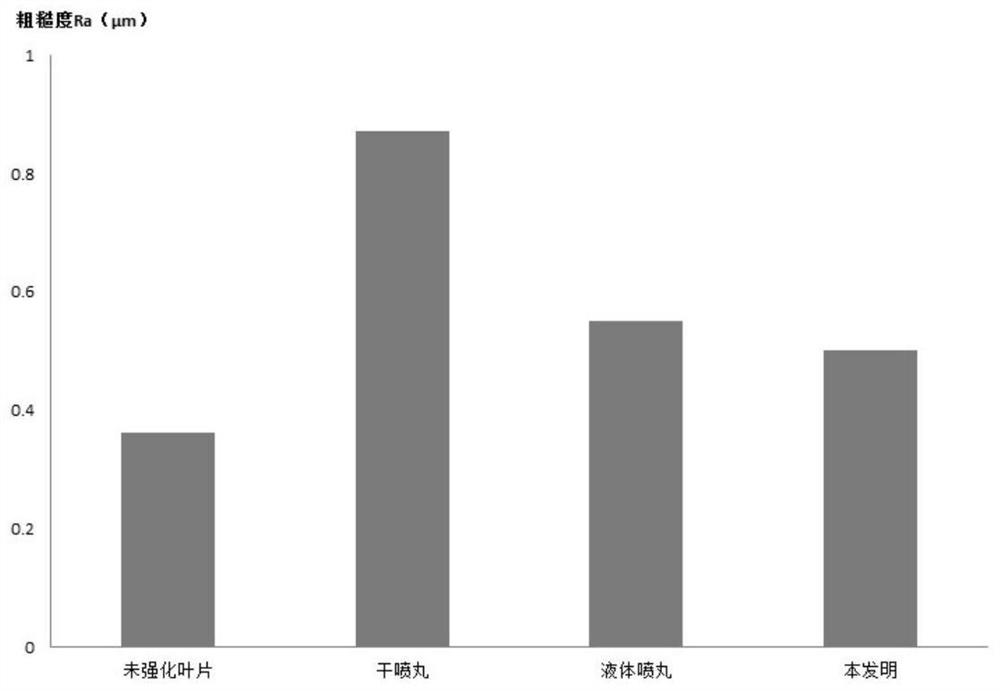

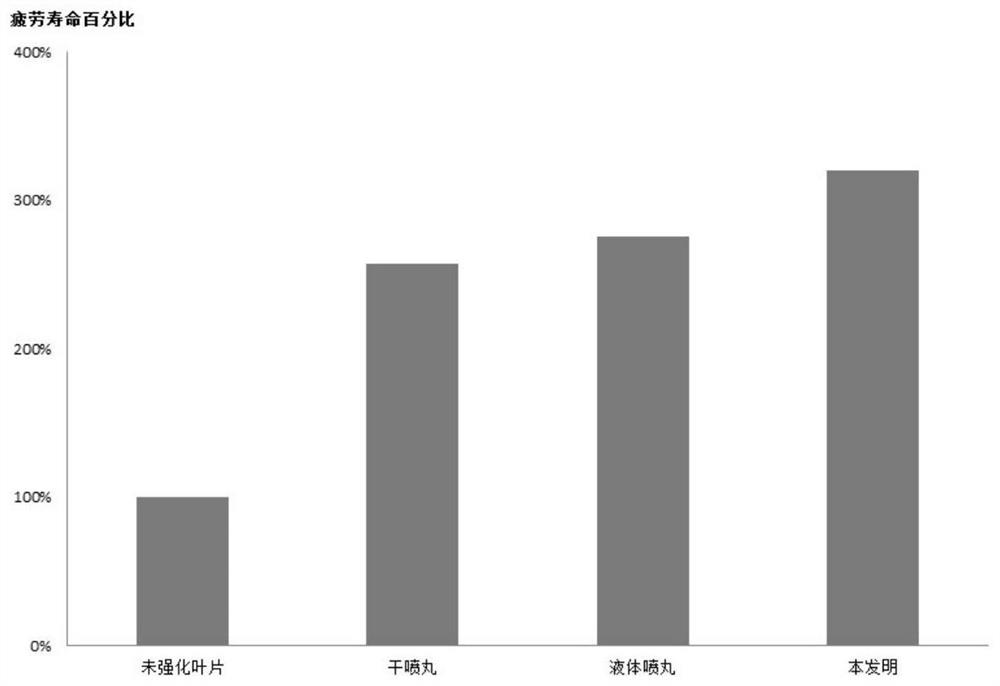

A composite surface and surface strengthening technology, applied in the field of surface strengthening, can solve problems such as insufficient surface roughness, large dispersion of blade surface residual stress, and insufficient blade fatigue life, etc., to achieve good surface residual compressive stress and roughness, Improved quality stability and high blade fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A blade composite surface strengthening method, comprising the following steps:

[0032] Step 1: Pre-treatment of surface strengthening on all surfaces of blades by means of vibratory finishing;

[0033] Step 2: Clamp the blade for the first time, put the blade into the liquid shot blasting equipment, expose the blade body, transition fillet and edge plate, use the mixed grinding liquid of projectile and oil to hit the blade surface, and complete the blade body liquid Dismantle tooling after shot peening;

[0034] Step 3: Clean the blade to remove the oil stain attached to the surface of the blade after processing;

[0035] Step 4: Carry out the second clamping of the blade, put the blade into the dry shot blasting equipment, expose the tenon of the blade, and use the projectile to hit the surface of the blade;

[0036] Step 5: Carry out the third clamping of the blade, put the blade into the dry shot peening equipment, expose the blade body, transition fillet and edg...

Embodiment 2

[0040] Further, in the step 1, after the surface strengthening pre-treatment is carried out on all surfaces of the blades by means of vibratory finishing, the surface roughness of the blades is checked, and the surface of the blades vibrating and brightening is not allowed to have residual machining traces and abrasive scratches. The surface roughness of the blade after vibrating polishing should satisfy Ra≤0.4μm.

Embodiment 3

[0042] Further, in the step 1 and step 6, alumina particles of different specifications are selected as the vibrating polishing abrasive, and the particle shapes include cylindrical, triangular prism, spherical, and ellipsoidal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com