Absorbent for removing sulfur dioxide in flue gas and application thereof

A technology of sulfur dioxide and absorbent, which is used in the absorbent for removing sulfur dioxide gas in flue gas, energy saving and environmental protection industry, and achieves the effect of reducing equipment material requirements, strong absorption performance and realizing resource reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

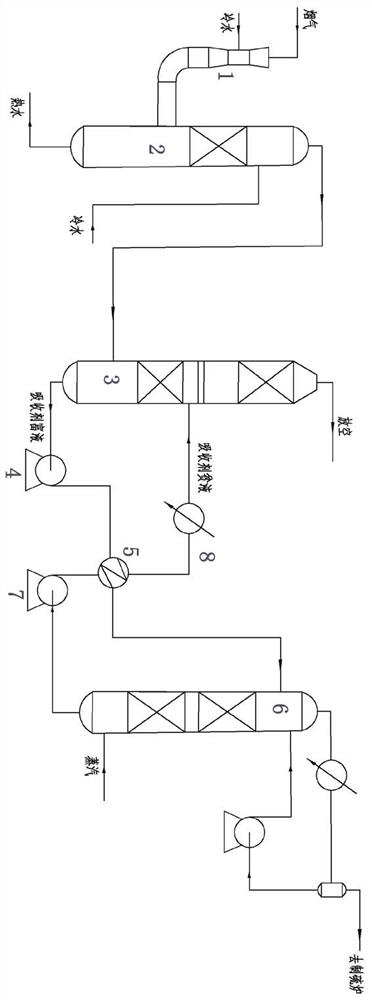

Method used

Image

Examples

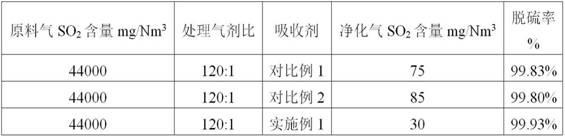

Embodiment 1

[0035] An absorbent for removing sulfur dioxide in flue gas, containing 12.5% of 4,4'-(1,2-ethylidene)bimorpholine and 12.5% of 4,4'-(oxybis (Methylene)) Dimorpholine as the main absorption component, also contains 0.05% of 4-butylamino-2,2,6,6-tetramethylpiperidine as heat stable salt inhibitor, the balance is water, The absorbent has a pH of 10.5.

Embodiment 2

[0037] An absorbent for removing sulfur dioxide in flue gas, containing 12.5% of 4,4'-(1,2-ethylidene)bimorpholine and 12.5% of 4,4'-(oxybis (Methylene)) dimorpholine as the main absorption component, also contains 0.01% of 4-butylamino-2,2,6,6-tetramethylpiperidine as heat stable salt inhibitor, the balance is water, The absorbent has a pH of 10.2.

Embodiment 3

[0039] An absorbent for removing sulfur dioxide in flue gas, containing 15% of 4,4'-(1,2-ethylidene)bimorpholine and 15% of 4,4'-(oxybis (Methylene)) Dimorpholine as the main absorption component, also contains 0.05% of 4-butylamino-2,2,6,6-tetramethylpiperidine as heat stable salt inhibitor, the balance is water, The absorbent has a pH of 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com