Flexible Bi2O2Se-based electrode material and preparation method and application thereof

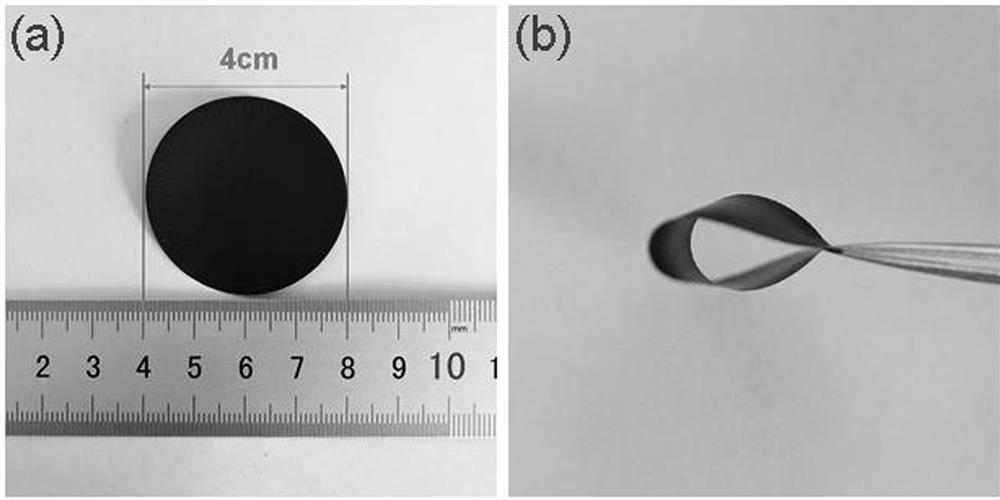

A base electrode and flexible technology, applied in the field of flexible Bi2O2Se-based electrode materials and their preparation, to achieve the effects of high yield, excellent flexibility, and stable cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

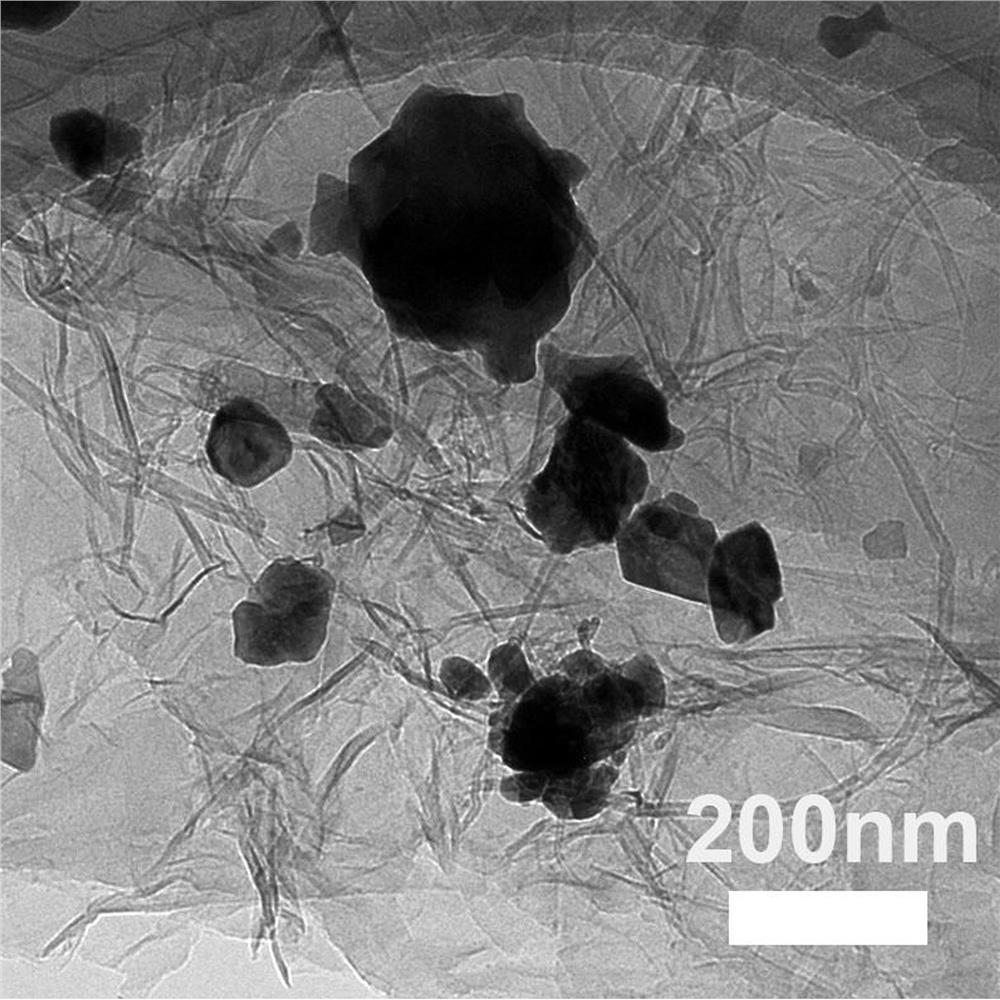

[0028] Embodiment 1: a kind of flexible Bi 2 o 2 Se-based electrode material, the flexible Bi 2 o 2 The Se-based electrode material is carbon nanotubes, bismuth salt and selenium source are mixed and dissolved, heated and reacted in a liquid phase oil bath, and then dried to obtain a powder. Bi 2 o 2 Se-based electrode material.

[0029] Specific steps are as follows:

[0030]Step 1: Mixing raw materials: Take 0.1g of polyvinylpyrrolidone and 1g of carbon nanotubes, add them to 100mL of ethylene glycol, then add 1g of bismuth source, stir for 1h (solution A); take 0.2g of selenium powder and sodium borohydride 0.2g was added to 10mL deionized water, stirred for 1h (solution B), and the two solutions were ultrasonically oscillated at an ultrasonic frequency of 60kHz for 1h;

[0031] Step 2: The solution in step (1) was treated with argon gas, and then reacted in an oil bath at a temperature of 150°C for 30 minutes. After the reaction, Bi was obtained by centrifugation, w...

Embodiment 2

[0037] Embodiment 2: a kind of flexible Bi 2 o 2 Se-based electrode material, the specific preparation method is: the surfactant is cetyltrimethylammonium bromide, cetyltrimethylammonium bromide and carbon nanotubes are mixed according to the mass ratio of 0.1g and 10g, The source of bismuth is bismuth sulfate, SeO 2 Mix with the mass ratio of lithium aluminum hydride 1g and 0.1g, all the other methods are with embodiment 1.

Embodiment 3

[0038] Embodiment 3: a kind of flexible Bi 2 o 2 Se-based electrode material, the specific preparation method is: the surfactant is polyacrylonitrile, polyacrylonitrile and carbon nanotubes are mixed according to the mass ratio of 0.1g and 0.1g, the bismuth source is bismuth chloride, NaSeO 3 Mix with ascorbic acid 1g and 0.5g in mass ratio, and react in an oil bath at a temperature of 220°C for 300min to obtain Bi 2 Se 3 - Black powder of CNTs. All the other methods are described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com