Magnetic fluid filled MNF and FBG cascaded stress and magnetic field sensing device

A sensing device and ferrofluid technology, which is applied to the use of magneto-optical equipment for magnetic field measurement, measurement device, magnetic field size/direction and other directions, which can solve the problem of simple structure, insignificant interference effect, poor sensor performance, and small measurement range. and other problems, to achieve the effect of real-time monitoring and measurement, simple structure fabrication method, and small cross-influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following embodiments will describe the specific implementation of the stress and magnetic field sensing device in cascade connection of magnetic fluid filled MNF and FBG proposed by the present invention with reference to the accompanying drawings.

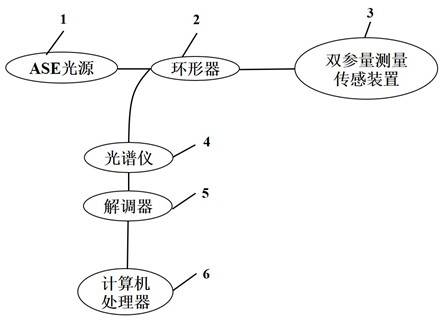

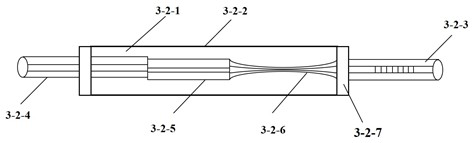

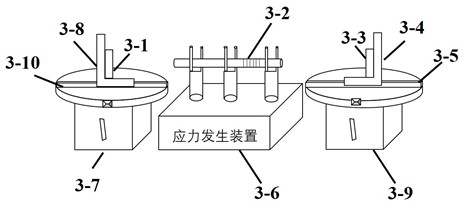

[0029] Such as figure 1 As shown, the present invention provides a structural diagram of a stress and magnetic field sensing device cascaded with magnetic fluid filled MNF and FBG, the ASE light source (1) emits a light beam that is transmitted to the circulator (2), and the output beam of the circulator (2) is transmitted to On the side of the single-mode optical fiber (3-2-4) of the sensing unit (3-2) of the dual-parameter measurement sensing device (3), the beam passes through the Mach-Zehnder interference part and is reflected at the FBG (3-2-3) , the reflected light is output to the spectrometer (4) through the circulator (2), when the displacement of the right displacement platform (3-5) in the dual-parameter mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com