Circumferential pressure filter material-free filtering device

A filtration device and annular pressure technology, which is applied in fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problems of large filter area, time-consuming filter material filtration, and large filter material particle size. , to achieve the effect of high filtration efficiency, energy saving and good filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, which should not be construed as a limitation of the present invention;

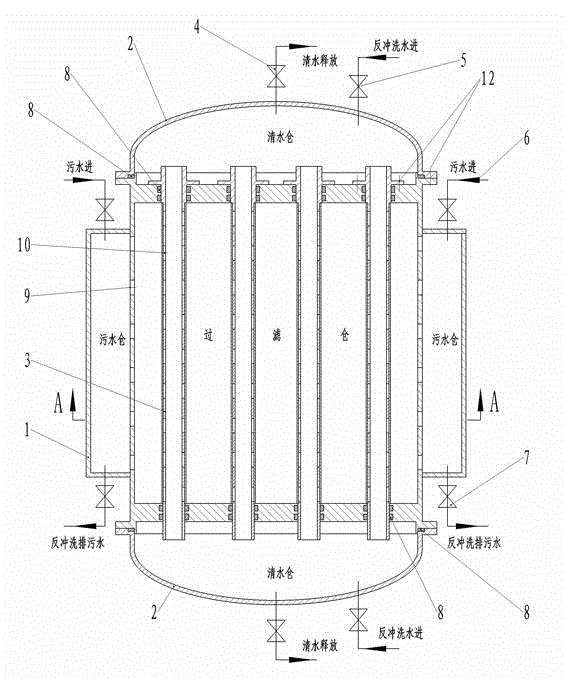

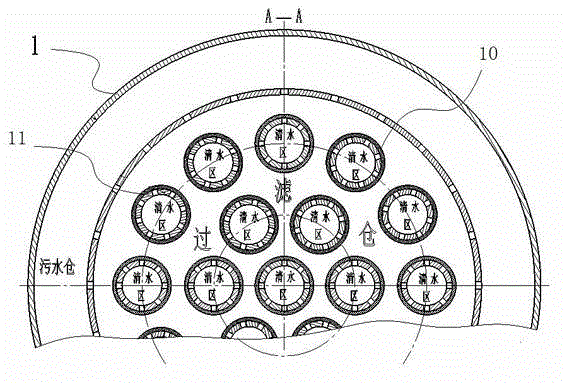

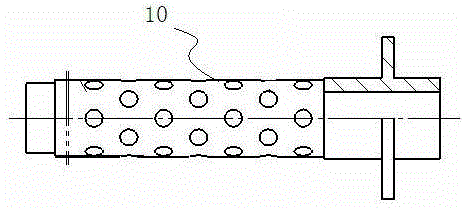

[0020] according to figure 1 with figure 2 As shown, the ring pressure filter device without filter material is composed of the filter body 1, the end cover 2, N filter pipes 3, the clean water release valve 4, the backwash water inlet valve 5, the sewage water inlet valve 6, the backwash sewage Outlet valve 7 and sealing ring 8 are composed. The peripheral area of the filter body 1 is a sewage bin, and the middle area is a filter bin. The filter body 1 and the end cover 2 form a clean water bin. The filter body 1 is equipped with There is a support pipe 10, the filter network pipe 3 is covered on the periphery of the support pipe 10, the clean water release valve 4 and the backwash water inlet valve 5 are arranged on the end cover 2, the sewage water inlet valve 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com