An annular pressure filtering device without filter material

A filtration device and annular pressure technology, which is applied to fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problems of large area of the filter, time-consuming filter material filtration, and small flow space. To achieve the effect of high filtration efficiency, energy saving and high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, which should not be construed as a limitation of the present invention;

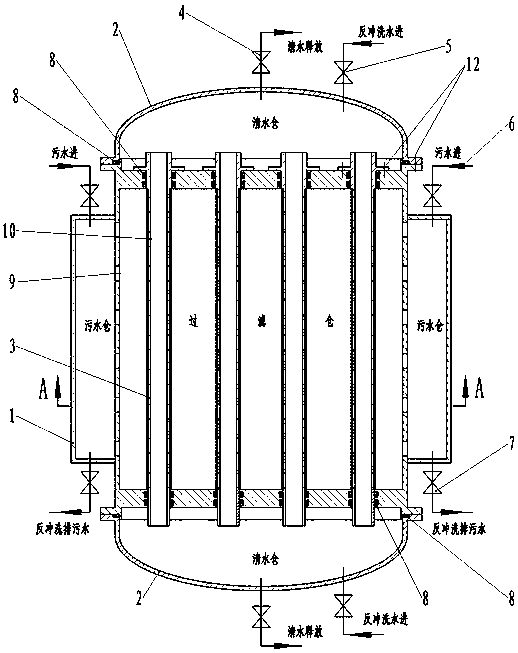

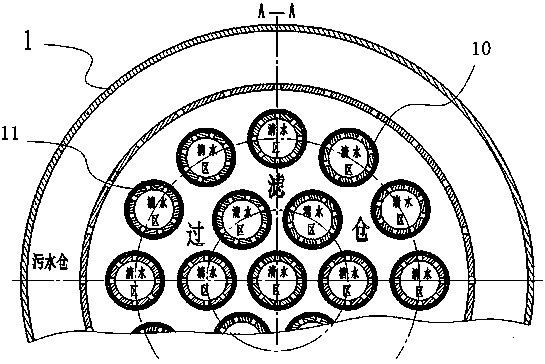

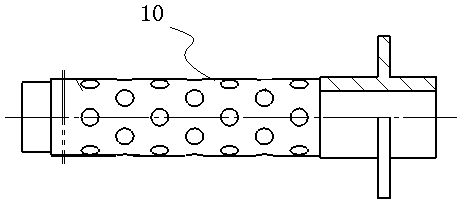

[0020] according to figure 1 and figure 2 As shown, the ring pressure filter device without filter material is composed of the filter body 1, the end cover 2, N filter pipes 3, the clean water release valve 4, the backwash water inlet valve 5, the sewage water inlet valve 6, the backwash sewage Outlet valve 7 and sealing ring 8 are composed. The peripheral area of the filter body 1 is a sewage bin, and the middle area is a filter bin. The filter body 1 and the end cover 2 form a clean water bin. The filter body 1 is equipped with There is a support pipe 10, the filter network pipe 3 is covered on the periphery of the support pipe 10, the clean water release valve 4 and the backwash water inlet valve 5 are arranged on the end cover 2, the sewage water inlet valve 6 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com