Automatic pump production line

An automated production line and workbench technology, applied in the field of automation, can solve problems such as the lack of a limit structure for water pumps, difficult cleaning of polishing equipment, and affecting processing effects, etc., to achieve the effects of preventing displacement, improving cleaning effects, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

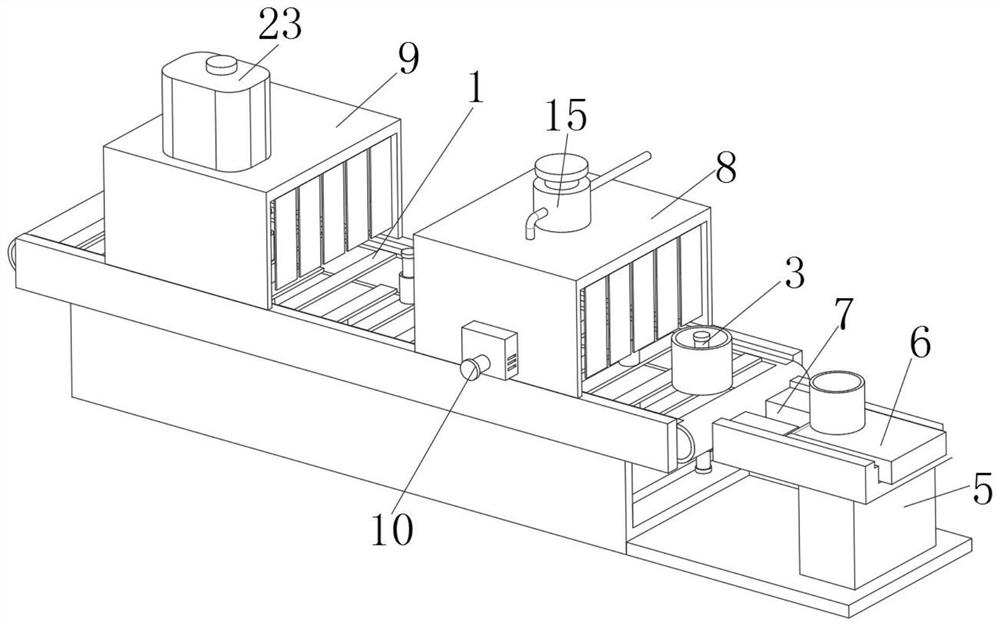

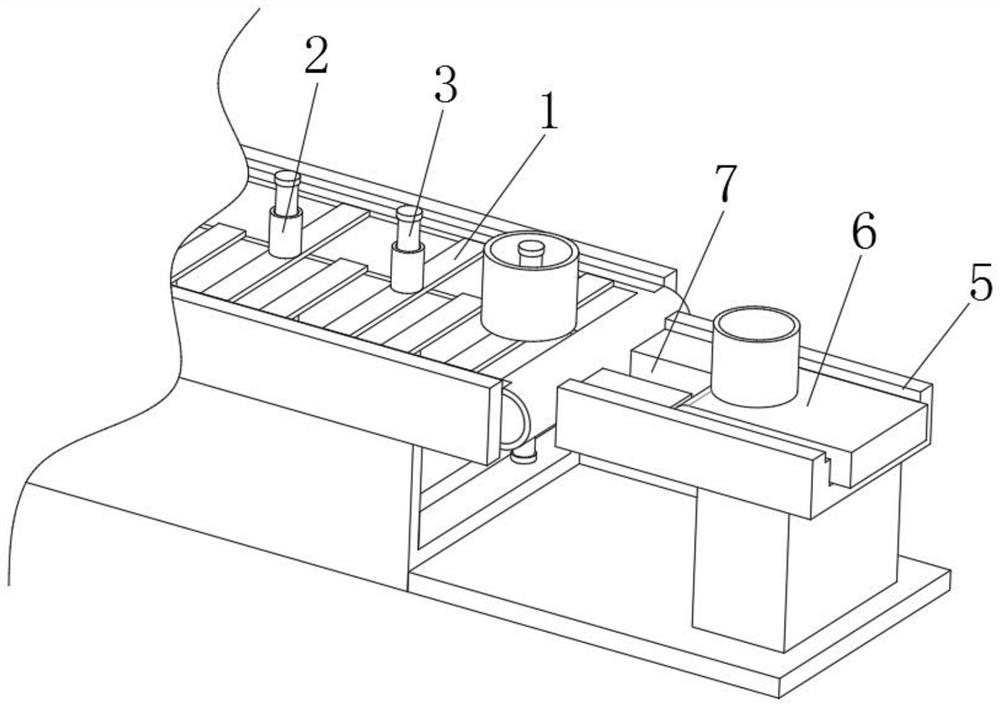

[0025] refer to Figure 1-2 , an automatic pump production line, including a workbench, the upper surface of the workbench is provided with a conveying assembly, the conveying assembly is composed of several conveying plates 1 and a conveying belt, and several conveying plates 1 form a hollowed-out conveying belt, conveying The upper surface of the board 1 is fixedly connected with the sleeve 2, the inner wall of the sleeve 2 is threadedly connected with the feeding column 3, the upper surface of the workbench is fixedly connected with the feeding table 5, and the upper surface of the feeding table 5 is provided with a feeding conveyor belt 6 , and the left side of the loading platform 5 is provided with a feeding port 7, the position of the feeding port 7 corresponds to the sleeve 2, and the feeding port 7 matches the sleeve 2.

[0026] In this embodiment, by setting the conveying plate 1, the sleeve 2 and the feeding column 3, and then cooperating with the feeding port 7 on ...

Embodiment 2

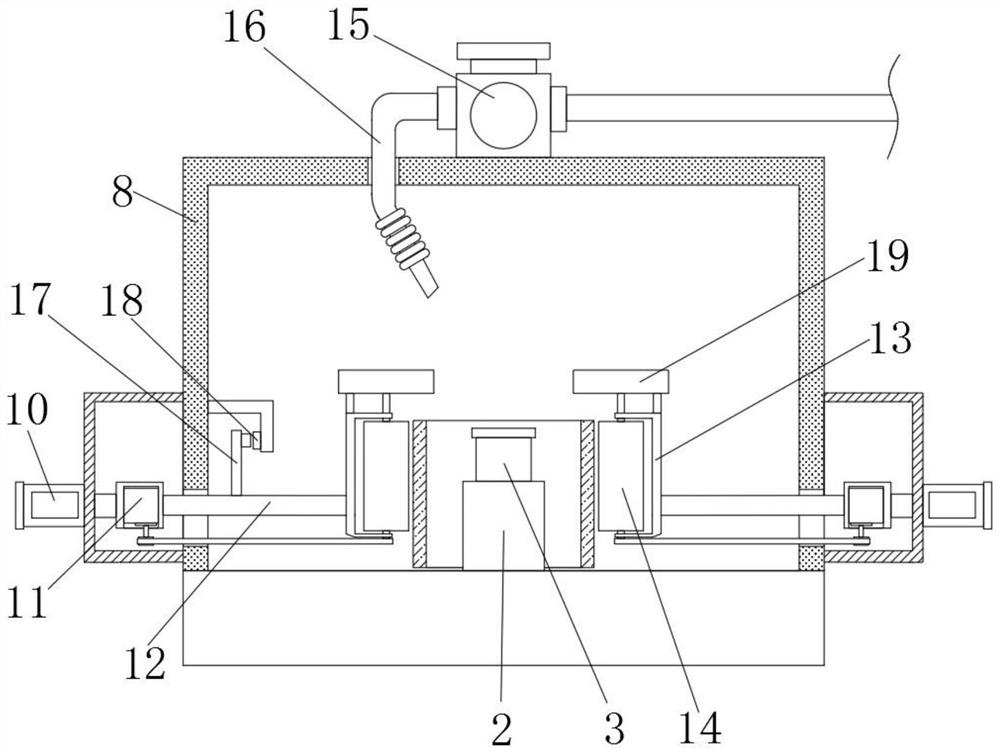

[0028] refer to Figure 3-4 , different from Example 1, the upper surface of the workbench is respectively provided with a polishing box 8 and a cleaning box 9, the conveying assembly passes through the polishing box 8 and the cleaning box 9 successively, and the front and rear surfaces of the polishing box 8 are provided with electric push rods 10. The telescoping end of the electric push rod 10 is fixedly connected with a driving motor 11, and the surface of the driving motor 11 is fixedly connected with an extension rod 12, and the end of the extension rod 12 extends to the inside of the polishing box 8, and is fixedly connected with a U-shaped plate 13 , the inner wall of the U-shaped plate 13 is rotatably connected with a polishing cylinder 14 through a rotating shaft.

[0029] The upper surface of polishing box 8 is provided with delivery pump 15, and the output end of delivery pump 15 is provided with shower nozzle 16, and the bottom end of shower nozzle 16 extends to t...

Embodiment 3

[0034] refer to Figure 5 , different from Embodiment 1, the upper surface of the cleaning box 9 is respectively provided with a cleaning agent box 23, and the upper surface of the cleaning box 9 is embedded with a water pipe, and the inner top wall of the cleaning box 9 is provided with a cleaning pump 24, and the cleaning pump The output end of 24 is provided with spray pipe 4, and the input end of cleaning pump 24 communicates with cleaning agent box 23 and water pipe respectively through three-way pipe.

[0035] In this embodiment, two mutually symmetrical cleaning rollers 22 are arranged in the cleaning box 9, and the compression spring 21 is used to drive the cleaning rollers 22 to be close to the shell surface of the water pump, not only applicable to water pump casings of different sizes, but also The cleaning effect is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com