Turning blade for machining small parts

A technology of small parts and inserts, which is applied in the field of turning inserts for small parts processing, can solve the problems that it is difficult to meet small diameter parts, reduce cutting resistance, difficult to meet the requirements of chip removal and chip breaking, and achieve enhanced chip space and enhanced The effect of chips, the effect of improving tool life and workpiece surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

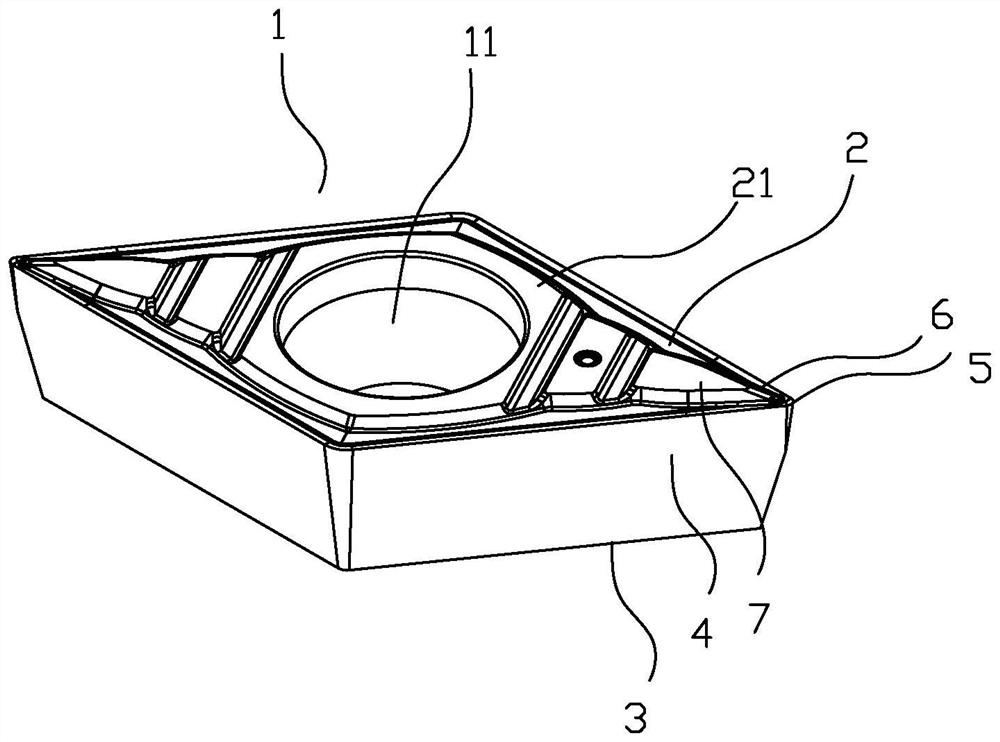

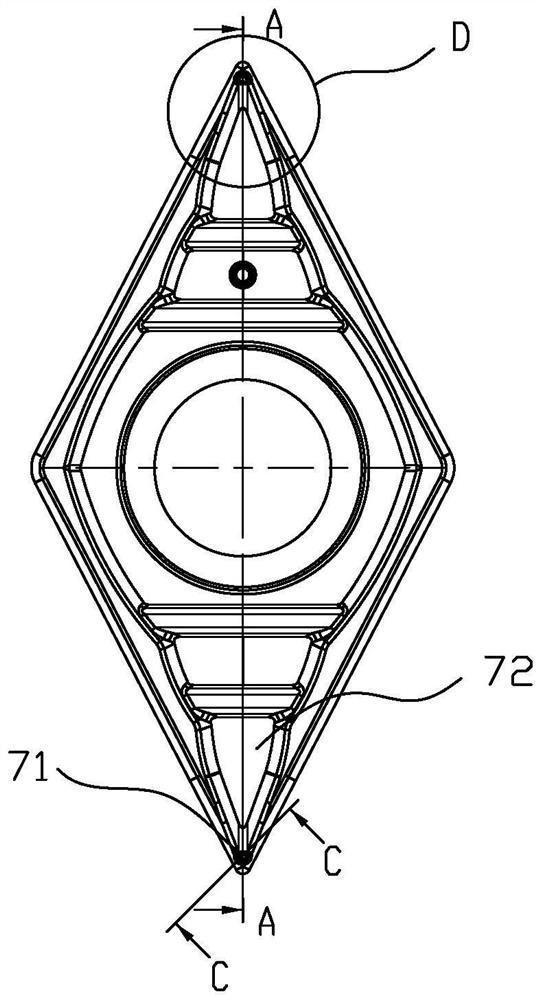

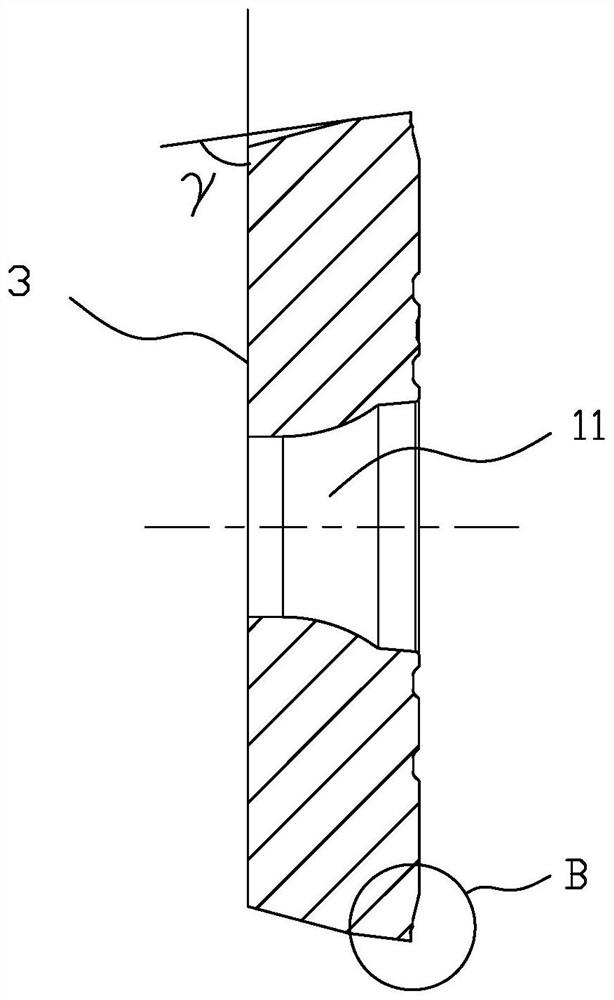

[0026] see Figure 1 to Figure 6 As shown, a turning insert for machining small parts of the present invention includes a insert body 1; the contour projection of the insert body 1 is a polygonal shape; as figure 2 As shown, the contour projection of the blade body of this embodiment is a rhombus shape, and among the four corners of the rhombus shape of the blade body, two corners are acute angles; the blade body 1 has an upper surface 2, a lower surface 3 and the side 4 connected between the upper and lower surfaces; the middle part of the blade body 1 is provided with a screw locking hole 11 passing through the upper and lower surfaces; in the blade body, in the acute corner of the blade body 1 , the upper surface 2 intersects with the side surface 4 to form a cutting edge 5; the cutting edge 5 includes an arc cutting edge 51 corresponding to the corner tip and a line segment cutting edge 52 connected to both sides of the arc cutting edge; In this embodiment, the line segm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com