Method for connecting thin film and lead wire by using spraying process

A wire and film technology, applied in the field of wire fixing, can solve problems such as poor temperature resistance, unstable transmission signals, and infirmity, and achieve the effects of reliable fixing, small thickness, and smooth connection nodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

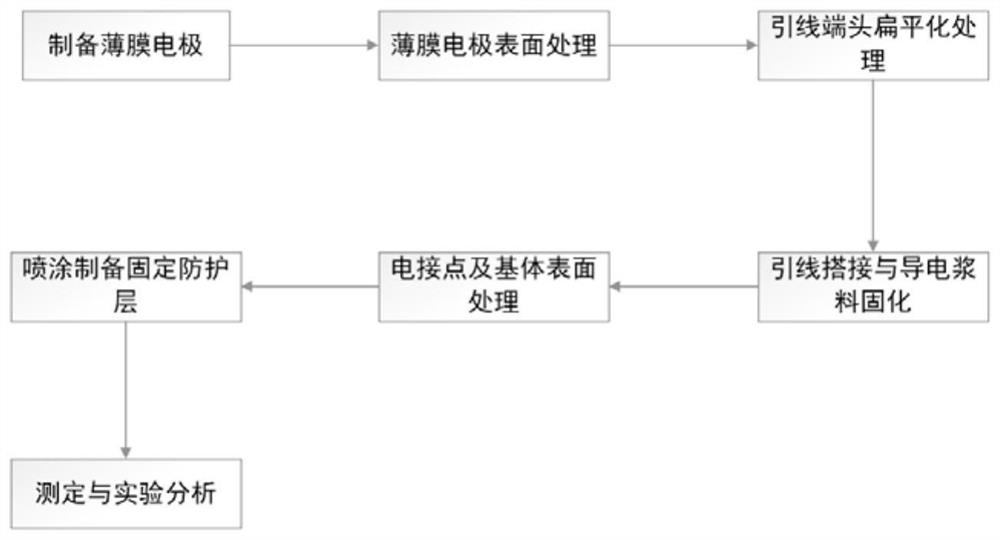

Method used

Image

Examples

Embodiment 1

[0035] An embodiment of the present invention is a method for connecting a film and a lead by using a spraying process.

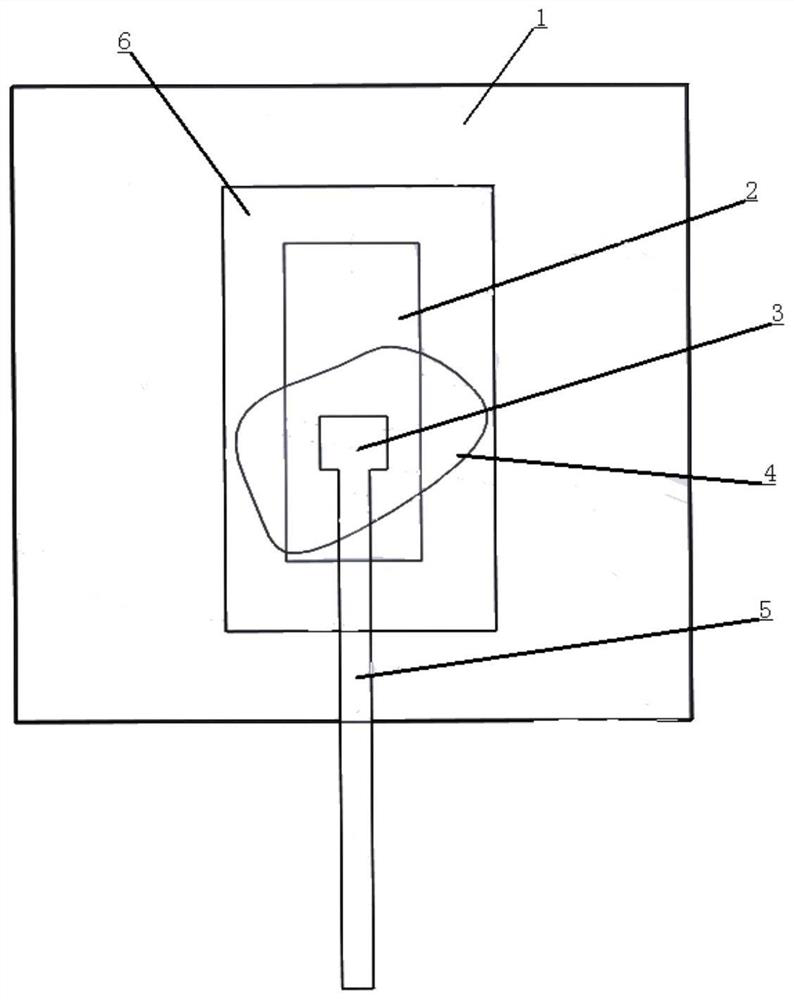

[0036] Its specific structure is: there is a thin-film thermocouple on the surface (1) of the planar ceramic substrate, and there is a thin-film electrode (2) at the bottom, and the connection between the thin-film electrode and the lead wire (3) is sequentially from inside to outside: conductive paste ( 4) A copper lead wire (5) with a diameter of 2 mm, a fixed protective layer (6) with a thickness of 160 μm, wherein the end of the copper lead wire is pressed into a flat shape before use, and the fixed protective layer is prepared by plasma spraying technology. The above-mentioned method for connecting a film and a lead by a spraying process comprises the following steps:

[0037] Step 1: using plasma to clean the thin film electrode on the surface of the substrate, the operating parameters of the plasma are;

[0038] Step 2: Press the lead end of Φ2mm in...

Embodiment 2

[0043] An embodiment of the present invention is a method for connecting a film and a lead by using a spraying process.

[0044] Its specific structure is: there is a thin-film thermocouple on the surface (1) of a cylindrical ceramic substrate of Φ15mm, and a thin-film electrode (2) exists at the bottom, and the connection between the thin-film electrode and the lead wire (3) is sequentially from inside to outside: conductive paste (4), a copper lead wire (5) with a diameter of 4 mm, and a fixed protective layer (6) with a thickness of 200 μm, wherein the end of the copper lead wire is pressed into a flat shape before use, and the fixed layer protective layer is prepared by plasma spraying technology.

[0045] The above-mentioned method for connecting a film and a lead by a spraying process comprises the following steps:

[0046] Step 1: using plasma to clean the thin film electrode on the surface of the substrate, the operating parameters of the plasma are;

[0047] Step 2: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com