Nitrocellulose membrane and preparation method thereof

A technology of nitrocellulose membrane and scraping membrane, applied in chemical instruments and methods, other chemical processes, ion exchange and other directions, can solve problems such as affecting the quality of nitrocellulose membrane, impurity can not be discharged in time, etc., to achieve perfect effective pore size, The effect of improving porosity and smoothing membrane structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of NC film in this paper, comprises the following steps:

[0050] Step 1, preparation of nitrocellulose membrane solution;

[0051] Step 2, degassing the nitrocellulose membrane solution in step 1 to obtain a nitrocellulose membrane concentrate;

[0052] Step 3: Scrape the nitrocellulose membrane concentrate after degassing in step 2 to form a film, and use a scraper tool to scrape the film on a clean tempered glass plate;

[0053] Step 4, shaping the nitrocellulose membrane formed by scraping the membrane in step 3, putting it into a gel water bath at a constant temperature, and undergoing water treatment to obtain the shaped nitrocellulose membrane;

[0054] Step five, drying the nitrocellulose membrane after setting in step four.

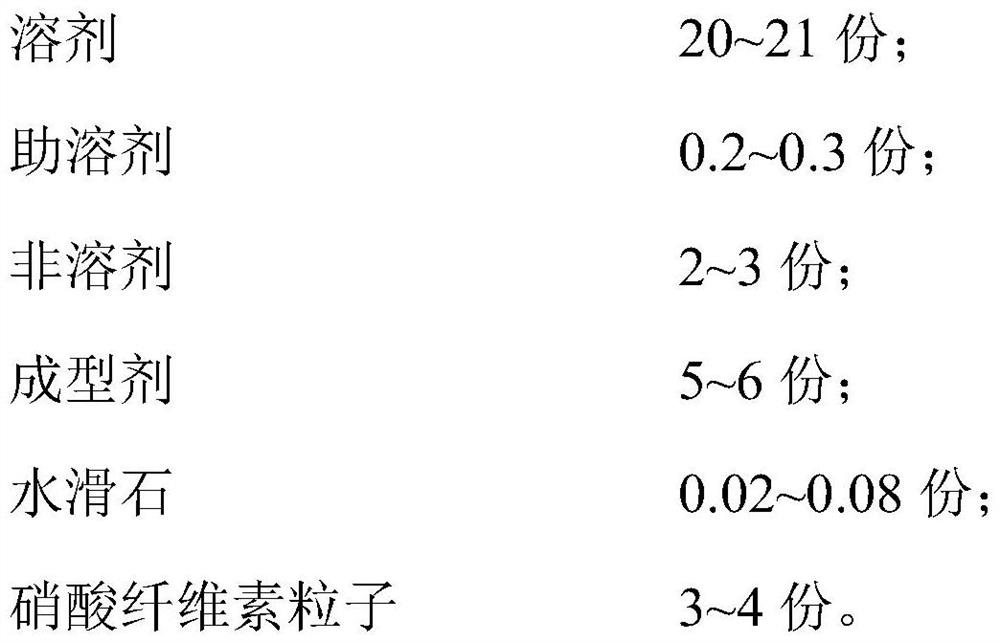

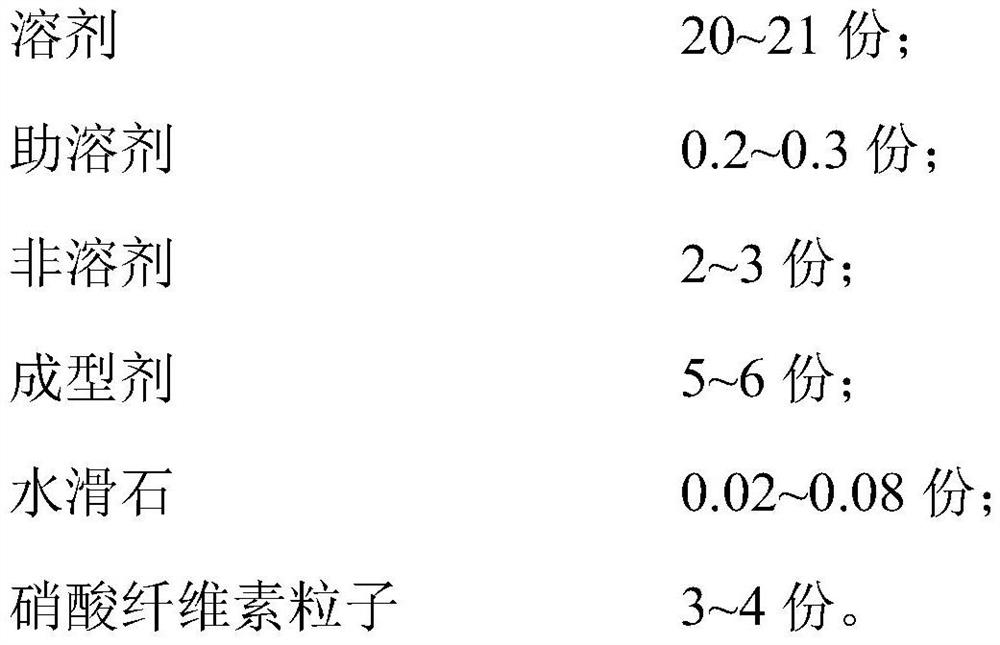

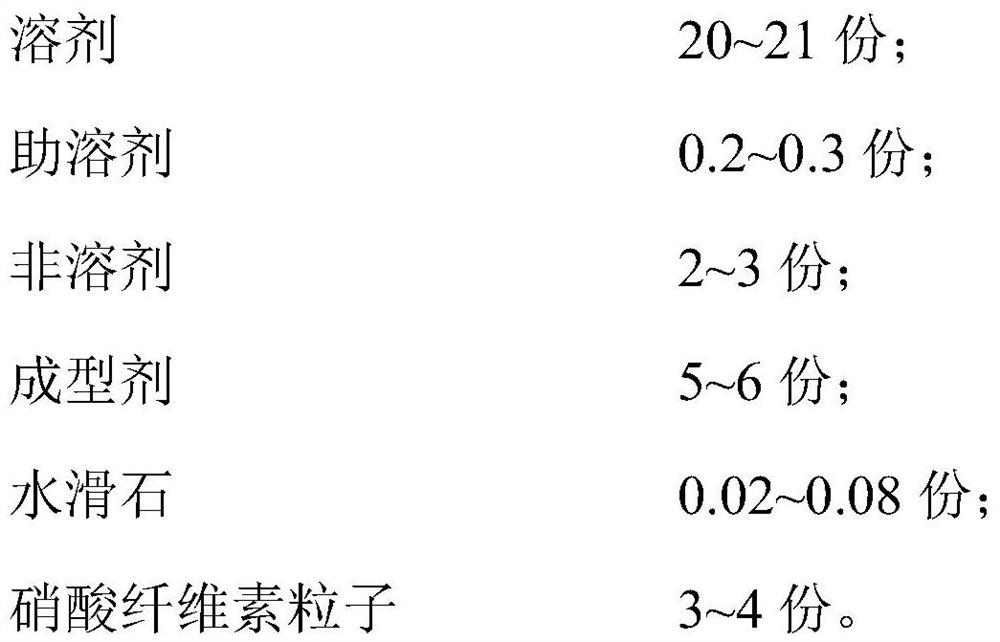

[0055] The nitrocellulose membrane solution is prepared from the following materials in parts by weight:

[0056]

[0057] The solvent includes one of N,N-dimethylformamide and N,N-dimethylacetamide or two of t...

Embodiment 1

[0065] (1) Preparation of nitrocellulose membrane solution: Pour 0.02g of hydrotalcite, 20g of N,N-dimethylacetamide, and 3g of nitrocellulose particles into the reaction device for stirring. The stirring time is more than 4h. This process is carried out at room temperature. Then add 0.2g of acetone, 5g of polysulfone, and 2g of polyvinylpyrrolidone and continue to stir for 24 to 36 hours at a temperature of 60°C. Pay attention to the content of solids in the reaction device until they are completely dissolved;

[0066] (2) Put the prepared NC membrane liquid into a dry environment and let it stand for defoaming. During this process, pay attention to foreign matter pollution and keep the dry environment clean;

[0067] (3) Before starting the scraping process, it is recommended to clean the scraper glass with alcohol, then rinse it with deionized water and dry it. Pour the NC film solution onto the glass plate, scrape the film on the glass plate at a constant speed with a spat...

example 2

[0072] Example 2 Preparation of nitrocellulose membrane solution (1) is to pour 0.02g hydrotalcite, 20g N,N-dimethylacetamide, and 3g nitrocellulose particles into the reaction device for stirring. The stirring time is greater than 4h. Then add 0.2g of acetone, 5g of polysulfone, and 2g of polyvinylpyrrolidone and continue to stir for 24 to 36 hours at a temperature of 60°C. Pay attention to observe the content of solids in the reaction device until they are completely dissolved; the subsequent steps are the same as in Example 1 (2) ~ (6).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com