Integrated device and method for preparing sulfur by synergistic regeneration and reduction of active coke

A technology of active coke regeneration and active coke, which is applied in the direction of chemical instruments and methods, sulfur compounds, sulfur preparation/purification, etc., which can solve the problems of increasing operation cycle and control difficulty, complex adsorbent preparation process, and large diffusion resistance in adsorption To achieve the effect of alleviating the shortage of sulfur resources, reducing the dependence on foreign countries, and realizing the utilization of sulfur resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

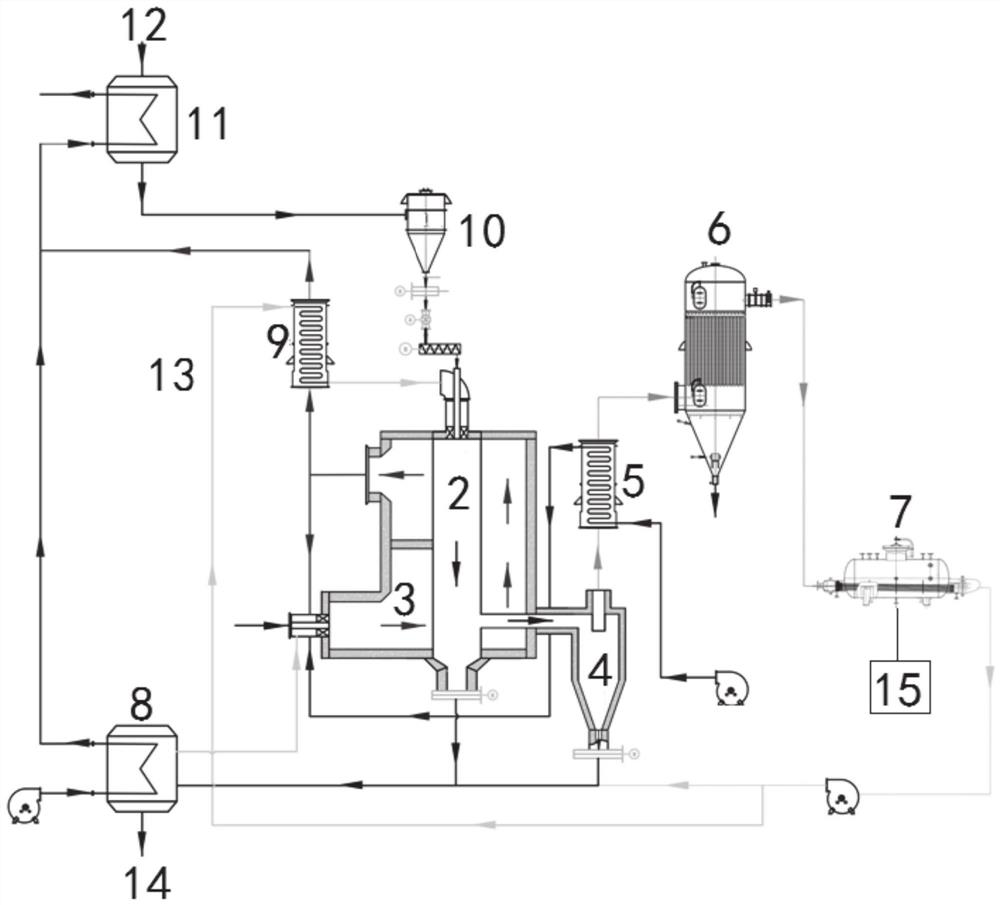

[0074] An integrated method for preparing sulfur by rapid regeneration and coordinated reduction of desulfurized powdered activated coke mainly includes the following steps:

[0075] Such as figure 1 As shown, what is discharged from the adsorption desulfurization unit is SO 2 The adsorbed sulfur-loaded powdery active coke 12 is saturated, the particle size is in the range of 50-200 μm, and the temperature is 60°C. First, it is sent to the active coke preheater 11 (which can be a variety of solid preheaters) for preheating and drying. The heating medium is the high-temperature air discharged from the regenerated powder coke cooler 8. The temperature of the high-temperature air is 400 ° C. Sulfur powder coke is heated to 200°C to reduce the precipitation of water at high temperature and reduce the concentration of sulfur-containing by-products, thereby increasing the conversion rate of sulfur.

[0076] The preheated and dried sulfur-loaded powder coke is sent to the active co...

Embodiment 2

[0083] An integrated method for preparing sulfur by rapid regeneration and coordinated reduction of desulfurized powdered activated coke mainly includes the following steps:

[0084]Such as figure 1 As shown, what is discharged from the adsorption desulfurization unit is SO 2 The adsorbed sulfur-loaded powdery activated coke 12 has a particle size in the range of 50-200 μm and a temperature of 100° C. First sent to the active coke preheater 11 (which can be a variety of solid preheaters) for preheating and drying. The heating medium is the high-temperature air discharged from the regenerated powder coke cooler 8. The temperature of the high-temperature air is 500 ° C. Sulfur powder coke is heated to 220°C to reduce the precipitation of water at high temperature and reduce the concentration of sulfur-containing by-products, thereby increasing the conversion rate of sulfur.

[0085] The preheated and dried sulfur-loaded powder coke is sent to the active coke storage device 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com