Water-soluble disinfecting composition comprising chlorhexidine or derivative thereof and having improved antibacterial durability, and fibrous disinfectant comprising same

A water-soluble, composition technology, applied in the direction of topical antibacterial agents, medical preparations containing active ingredients, drug delivery, etc., can solve the problems of reduced antibacterial durability, low solubility and stability, etc. Excellent absorption efficiency, the effect of improving potential toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0030] Hereinafter, the present invention will be described in detail.

[0031] Water-soluble disinfectant composition with improved antibacterial durability

[0032] The present invention provides a water-soluble disinfectant composition with improved antibacterial durability, which comprises chlorhexidine or a derivative thereof and a silicon-based emulsifier.

[0033] The "water-soluble disinfectant composition" in this specification is an external preparation containing a water-soluble solvent, and is characterized by not containing an alcoholic solvent. After the above-mentioned water-soluble disinfectant composition is applied to the human body such as the skin to be disinfected, the water-soluble solvent is volatilized to improve the skin-friendly effect, and the remaining components that have not been volatilized form a stable film on the human body such as the skin to be disinfected and act as a protective film. to disinfection. Moreover, the above-mentioned water...

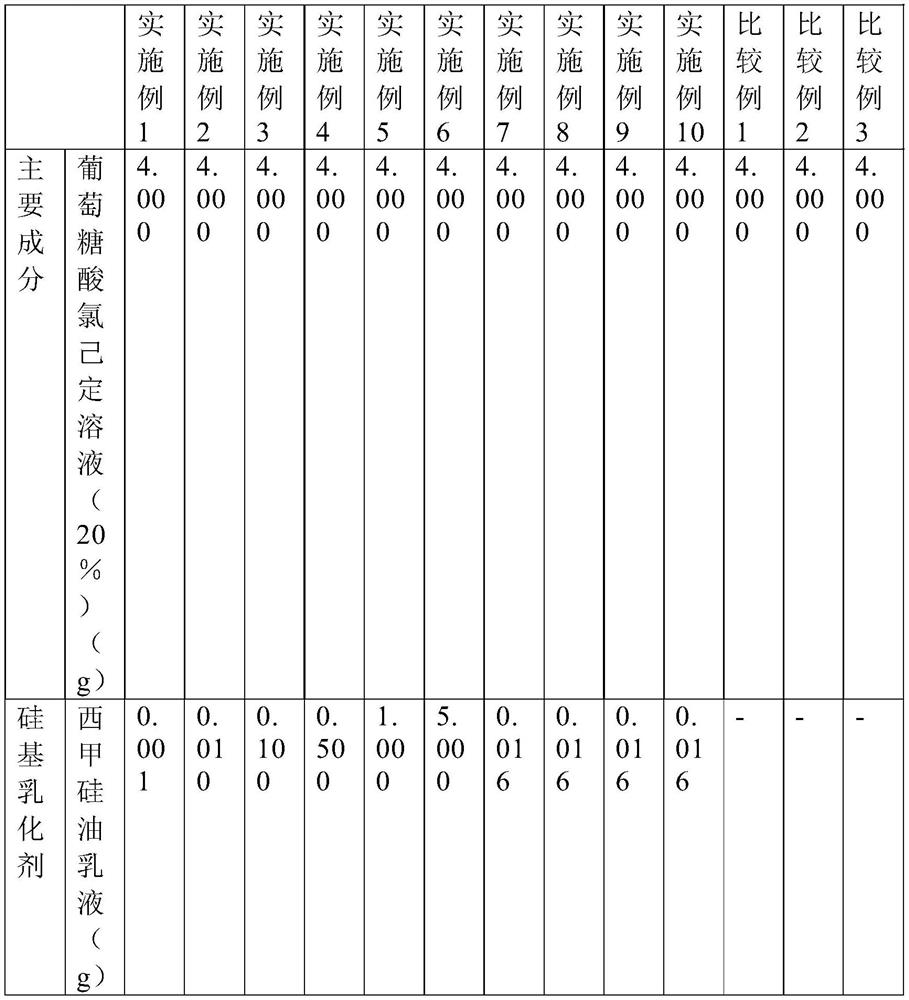

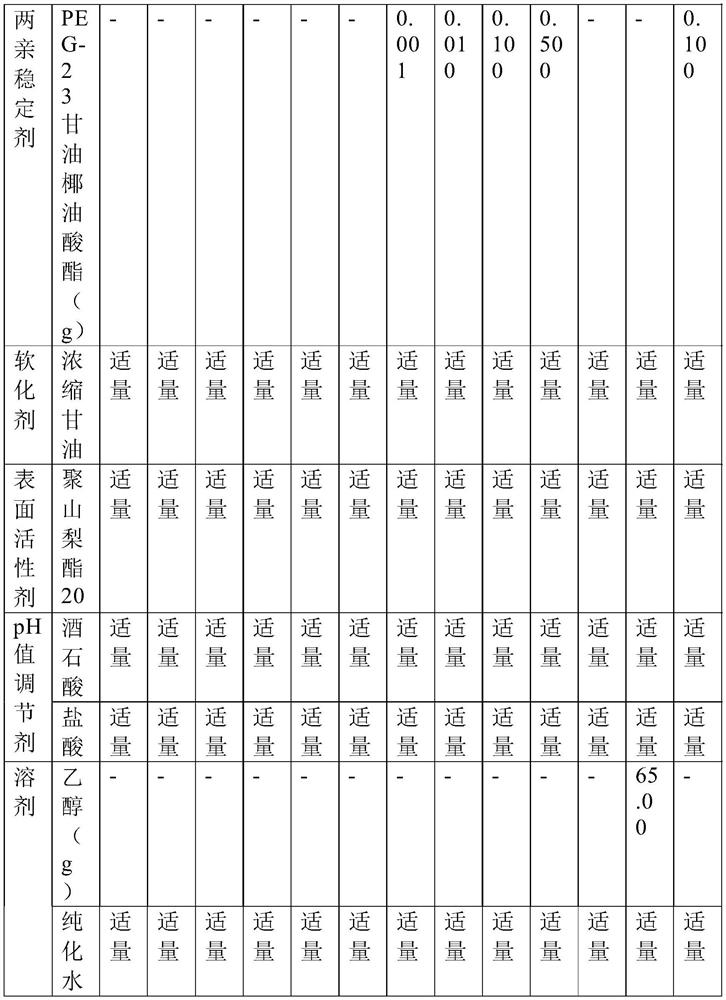

Embodiment 1~ Embodiment 10 and comparative example 1~ comparative example 3

[0058] A sanitizing composition was prepared by the composition of Table 1 below. Specifically, add chlorhexidine gluconate solution (20%) (source: MEDICHEM S.A., Spain) as main component; Simethicone emulsion (source: DOW CORNING Corp., U.S.) as silicon-based emulsifier; PEG-23 glycerin coconut oil Ester (source: Protameen Chemical, USA) was used as amphiphilic stabilizer; concentrated glycerin (source: SSPHARM, Korea) was used as softener; polysorbate 20 (source: Cawcorporation, Japan) was used as surfactant; tartaric acid and hydrochloric acid were used as pH value regulator; or ethanol as an alcoholic solvent and dissolved, and purified water was added to make the final volume 100 ml, and then filtered with a 0.2 μm membrane filter to prepare a disinfectant composition. At this point, the pH of the sanitizing composition is maintained at 4.5 to 6.5.

[0059] Table 1

[0060]

[0061]

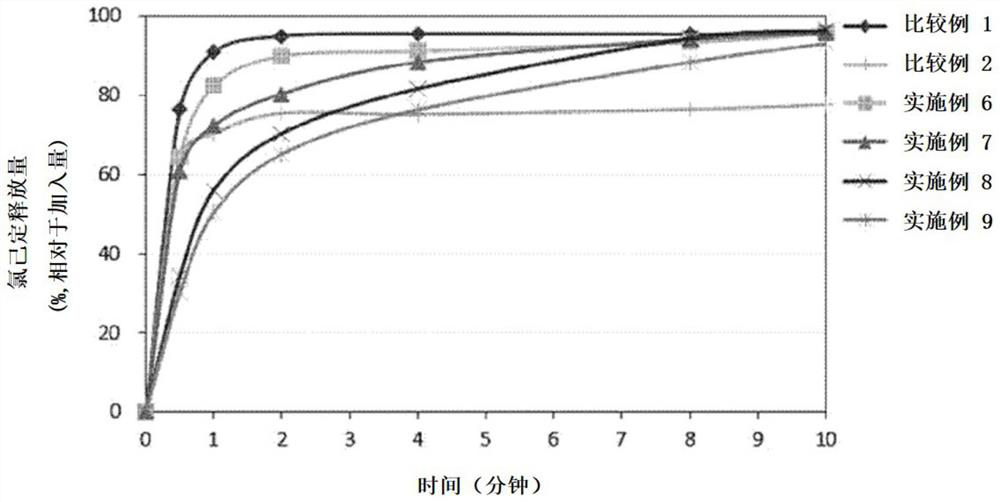

experiment example 1

[0062] Experimental Example 1: Measure the 50% cumulative mass particle size of the particles in the disinfectant composition Small distribution diameter, dispersion and zeta potential

[0063] As the silicon-based emulsifier in the sanitizing composition prepared in embodiment 1~embodiment 6 and comparative example 1, in order to make the content optimization of simethicone emulsion, in embodiment 1~embodiment 6 and comparative example 1 The prepared disinfectant composition was used as the object, and the 50% cumulative mass particle size distribution diameter, degree of dispersion, and zeta potential of the nanoparticles were measured by a Zeta-sizer, and the results are shown in Table 2.

[0064] Table 2

[0065]

[0066] As shown in Table 2, in the case of the disinfecting composition prepared in Examples 1 to 6, different from the disinfecting composition prepared in Comparative Example 1, Simethicone emulsion must be included as a silicon-based emulsifier. It is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| zeta potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com