Anti-electron radiation garment material and preparation method thereof

A technology of electronic radiation and clothing, applied in clothing, clothing, protective clothing, etc., can solve the problems of breeding a large number of bacteria and affecting the health of users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] An electronic radiation-proof clothing fabric is prepared by spinning reinforced yarns;

[0040] The reinforcing yarn is made by the following steps:

[0041] Soak the cotton yarn in the dipping solution, and after soaking for 8 hours at a temperature of 35°C, take out the cotton yarn and dry it to obtain the reinforced yarn;

[0042]The dipping solution comprises the following raw materials in parts by weight: 30 parts of modified graphene, 1,000 parts of deionized water, 5 parts of softener, and 20 parts of water-based polyurethane;

[0043] The dipping solution is made by the following steps:

[0044] The modified graphene was dispersed in deionized water, softener was added, and under the condition of a frequency of 3MHz, after ultrasonic treatment for 5 minutes, water-based polyurethane was added, and the ultrasonic treatment was continued for 20 minutes to obtain an impregnating liquid.

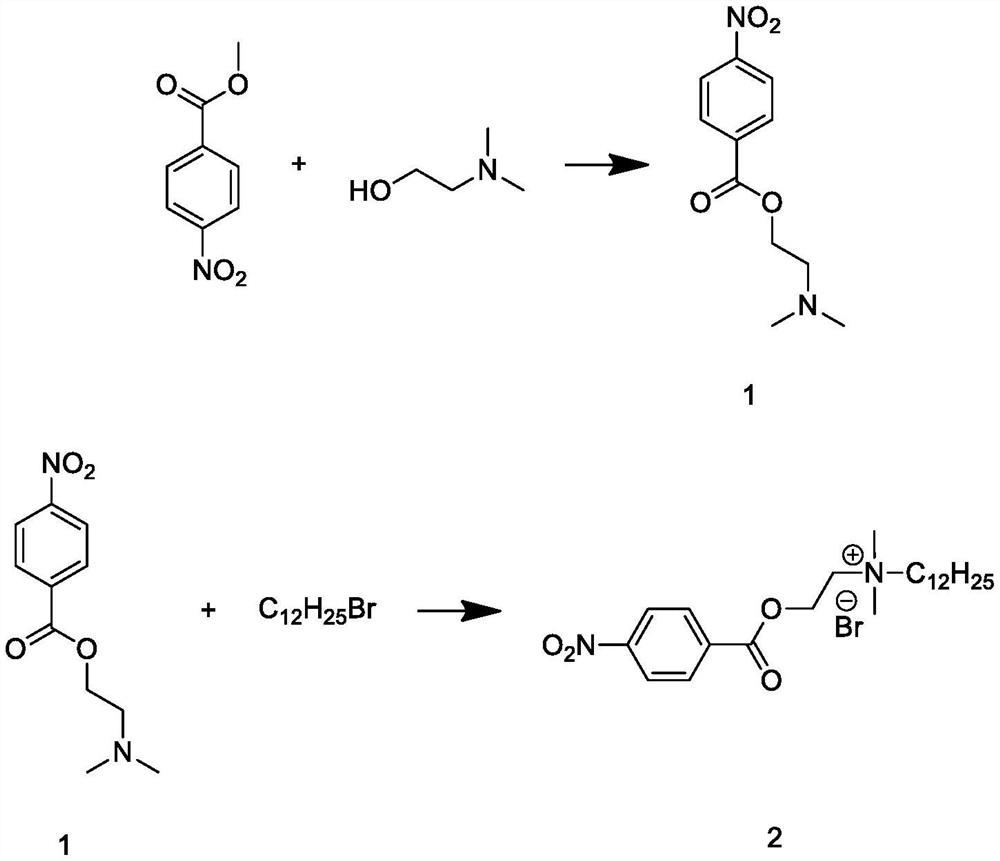

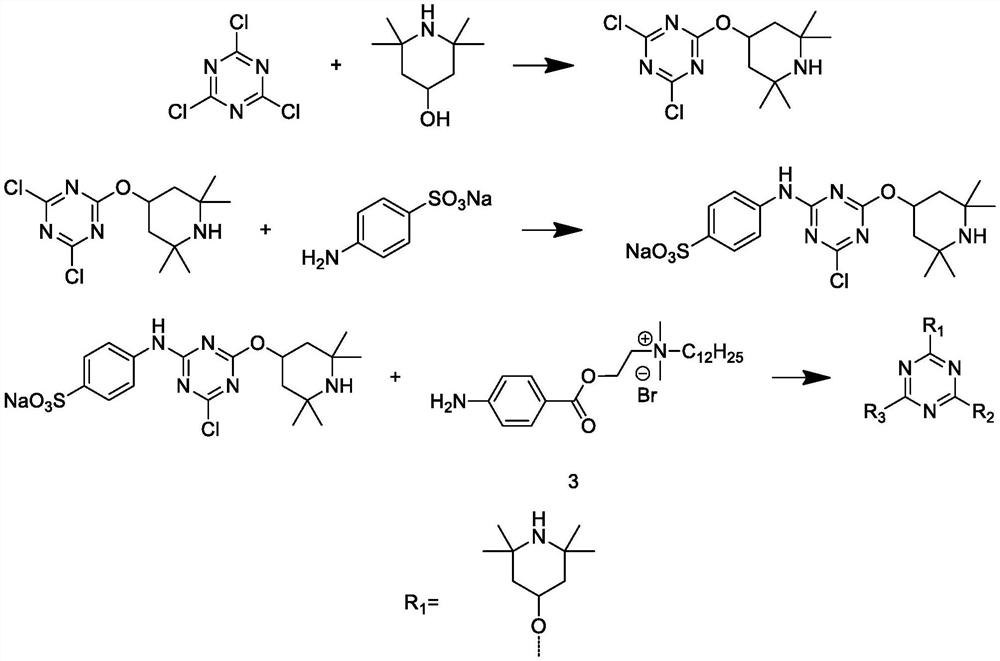

[0045] Described modified graphene is made by the following steps:

[004...

Embodiment 2

[0052] An electronic radiation-proof clothing fabric is prepared by spinning reinforced yarns;

[0053] The reinforcing yarn is made by the following steps:

[0054] Soak the cotton yarn in the impregnating solution, and after soaking for 10 hours at a temperature of 35°C, take out the cotton yarn and dry it to obtain the reinforced yarn;

[0055] Described immersion liquid comprises the following raw materials by weight: 35 parts of modified graphene, 1050 parts of deionized water, 6 parts of softener, and 23 parts of water-based polyurethane;

[0056] The dipping solution is made by the following steps:

[0057] The modified graphene was dispersed in deionized water, softener was added, and under the condition of a frequency of 3MHz, after ultrasonic treatment for 10 minutes, water-based polyurethane was added, and the ultrasonic treatment was continued for 20 minutes to obtain an impregnating liquid.

[0058] Described modified graphene is made by the following steps:

...

Embodiment 3

[0065] An electronic radiation-proof clothing fabric is prepared by spinning reinforced yarns;

[0066] The reinforcing yarn is made by the following steps:

[0067] Soak the cotton yarn in the impregnating solution, and after soaking for 8 hours at a temperature of 40 °C, take out the cotton yarn and dry it to obtain the reinforced yarn;

[0068] Described immersion liquid comprises the following raw materials by weight: 40 parts of modified graphene, 1100 parts of deionized water, 8 parts of softener, and 28 parts of water-based polyurethane;

[0069] The dipping solution is made by the following steps:

[0070] The modified graphene was dispersed in deionized water, softener was added, and under the condition of a frequency of 5MHz, after ultrasonic treatment for 5 minutes, water-based polyurethane was added, and the ultrasonic treatment was continued for 30 minutes to obtain an impregnating liquid.

[0071] Described modified graphene is made by the following steps:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com