Distribution optimization method of grain boundary characteristics based on friction stir processing of cupronickel alloy

A friction stir and distribution optimization technology, applied in the field of metal material deformation and heat treatment, to achieve the effect of optimizing the distribution of grain boundary characteristics, improving corrosion resistance, and optimizing grain boundary structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The distribution optimization method based on friction stir processing white copper alloy grain boundary characteristics according to the present invention comprises the following steps:

[0033] S1: Pretreatment of B10 white copper alloy, that is, solution treatment (treatment at 800°C for 30min, water quenching);

[0034] S2: Use the friction stir processing machine to perform friction stir processing on the white copper alloy plate. The rotation speed of the friction stir processing stirring head is 400 rpm, the feeding speed is 100 mm / min, the overlap ratio is 50%, and the reduction amount is 0.3 mm. as-processed samples;

[0035] S3: Perform annealing treatment at 700°C on the processed sample, and take it out for quenching after holding for 24 hours.

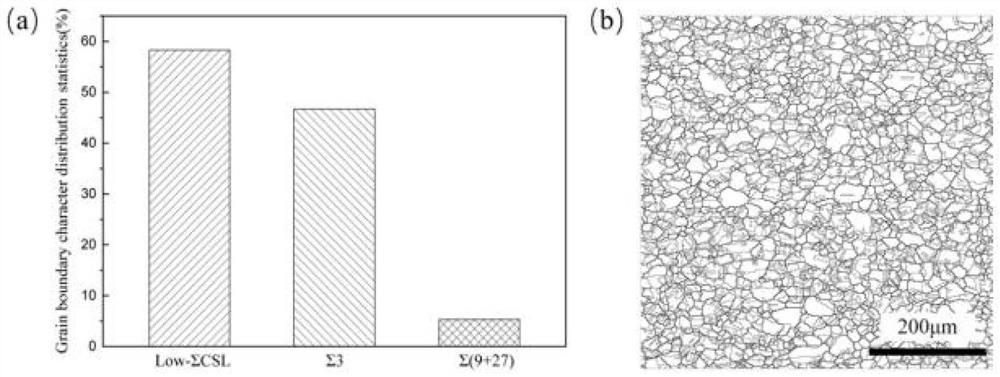

[0036] Determination of the distribution of grain boundary characteristics of the alloy: EBSD technology was used to observe and analyze the characteristic distribution of grain boundaries in the B10 cupronickel al...

Embodiment 2

[0038] The distribution optimization method based on friction stir processing white copper alloy grain boundary characteristics according to the present invention comprises the following steps:

[0039] S1: Pretreatment of B10 white copper alloy, that is, solution treatment (treatment at 800°C for 30min, water quenching);

[0040]S2: Use the friction stir processing machine to perform friction stir processing on the cupronickel alloy plate. The rotation speed of the friction stir processing stirring head is 600 rpm, the feeding speed is 100 mm / min, the lap rate is 50%, and the reduction amount is 0.3 mm. as-processed samples;

[0041] S3: Perform annealing treatment at 700°C on the processed sample, and take it out for quenching after holding for 24 hours.

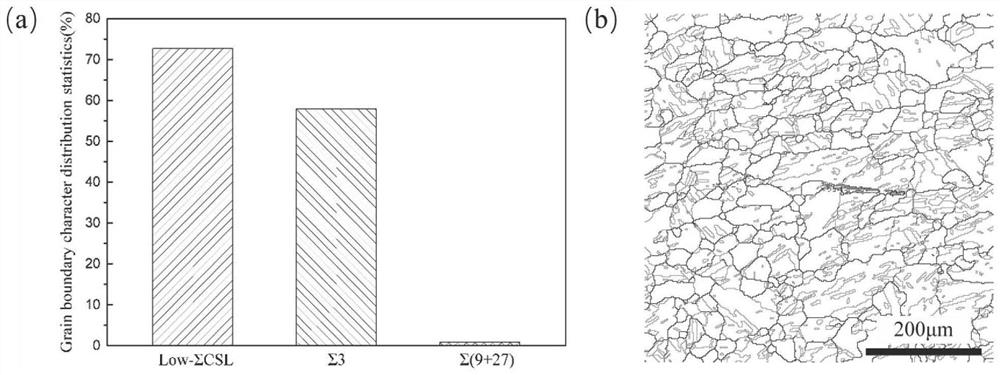

[0042] Determination of the distribution of grain boundary characteristics of the alloy: EBSD technology was used to observe and analyze the characteristic distribution of grain boundaries in the B10 cupronickel alloy aft...

Embodiment 3

[0044] The distribution optimization method based on friction stir processing white copper alloy grain boundary characteristics according to the present invention comprises the following steps:

[0045] S1: Pretreatment of B10 white copper alloy, that is, solution treatment (treatment at 800°C for 30min, water quenching);

[0046] S2: Use the friction stir processing machine to perform friction stir processing on the cupronickel alloy plate. The rotation speed of the friction stir processing stirring head is 800 rpm, the feed speed is 100 mm / min, the overlap ratio is 50%, and the reduction amount is 0.3 mm. Obtained as-processed samples;

[0047] S3: Perform annealing treatment at 700°C on the processed sample, and take it out for quenching after holding for 24 hours.

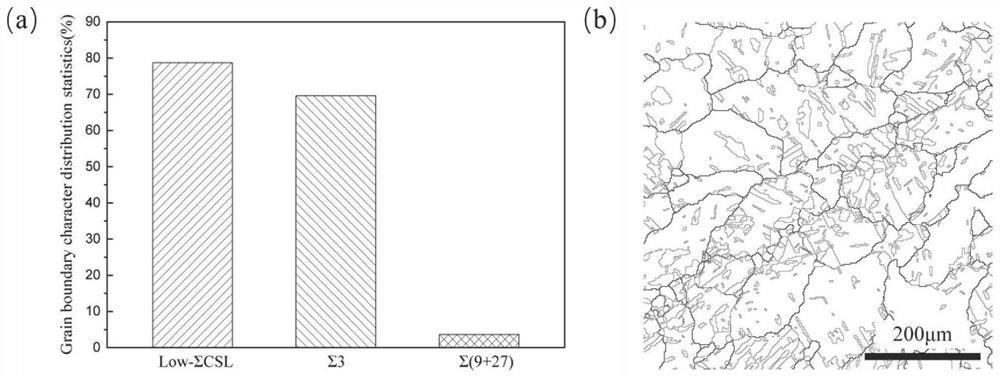

[0048] Determination of the distribution of grain boundary characteristics of the alloy: EBSD technology was used to observe and analyze the characteristic distribution of grain boundaries in the B10 cupronick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com