High-voltage non-inductive resistor and manufacturing method thereof

A technology of non-inductive resistors and manufacturing methods, applied in resistors, resistor manufacturing, resistor components and other directions, can solve the problems of poor resistance to short-term inrush current, complex structure, large volume, etc., and achieve excellent anti-oxidation performance, High mechanical strength, the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

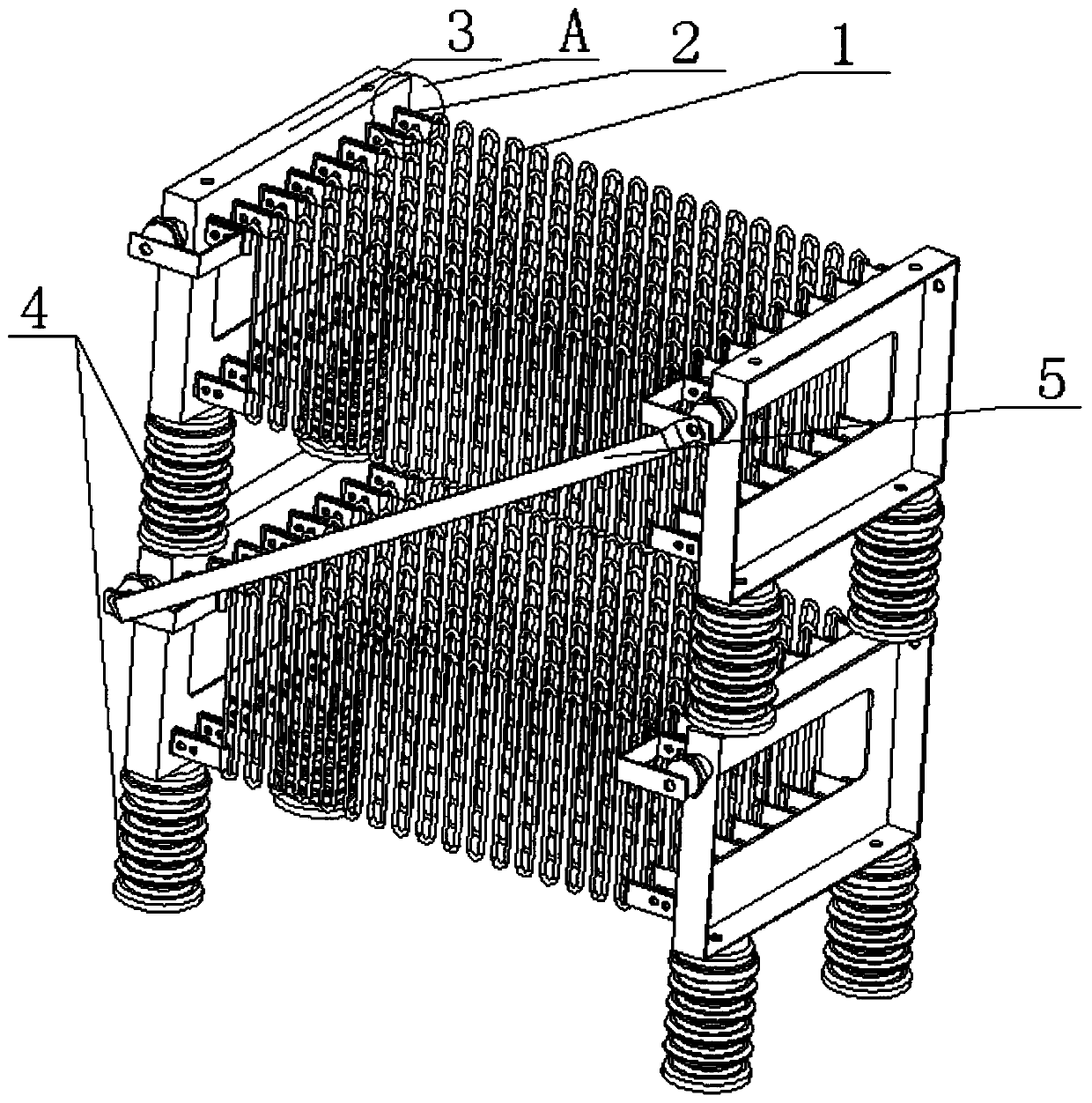

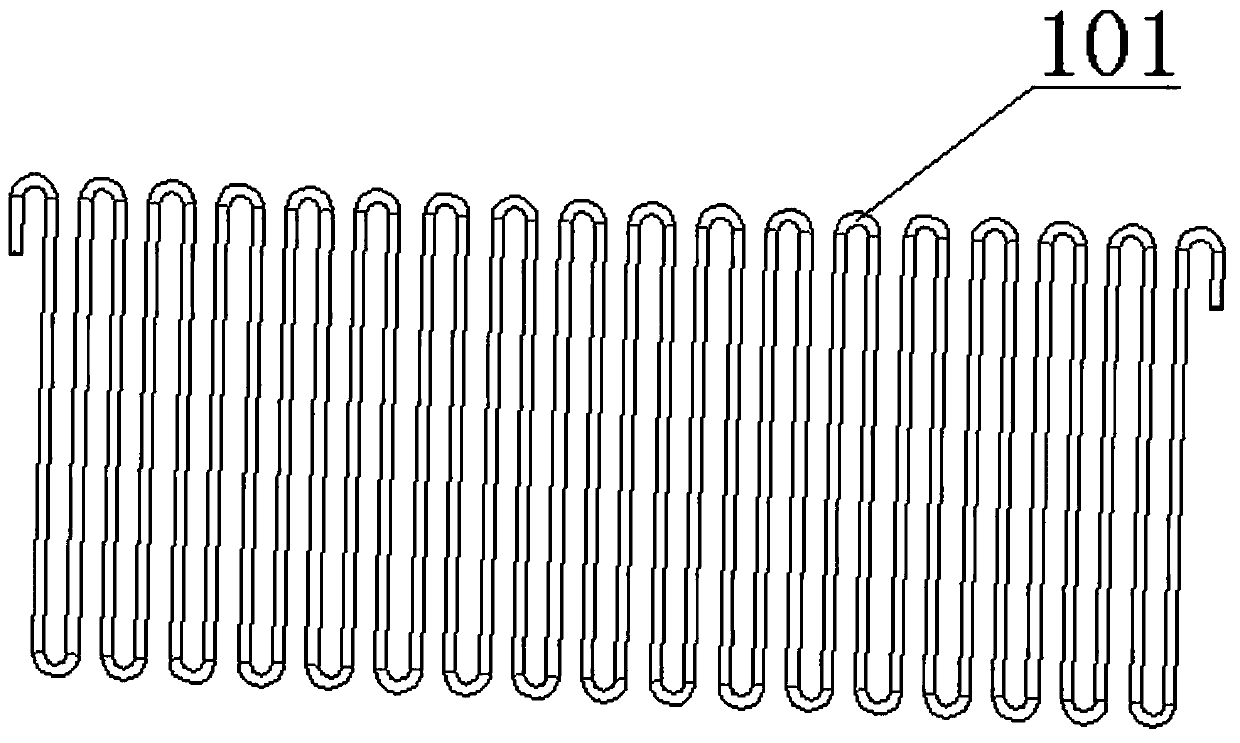

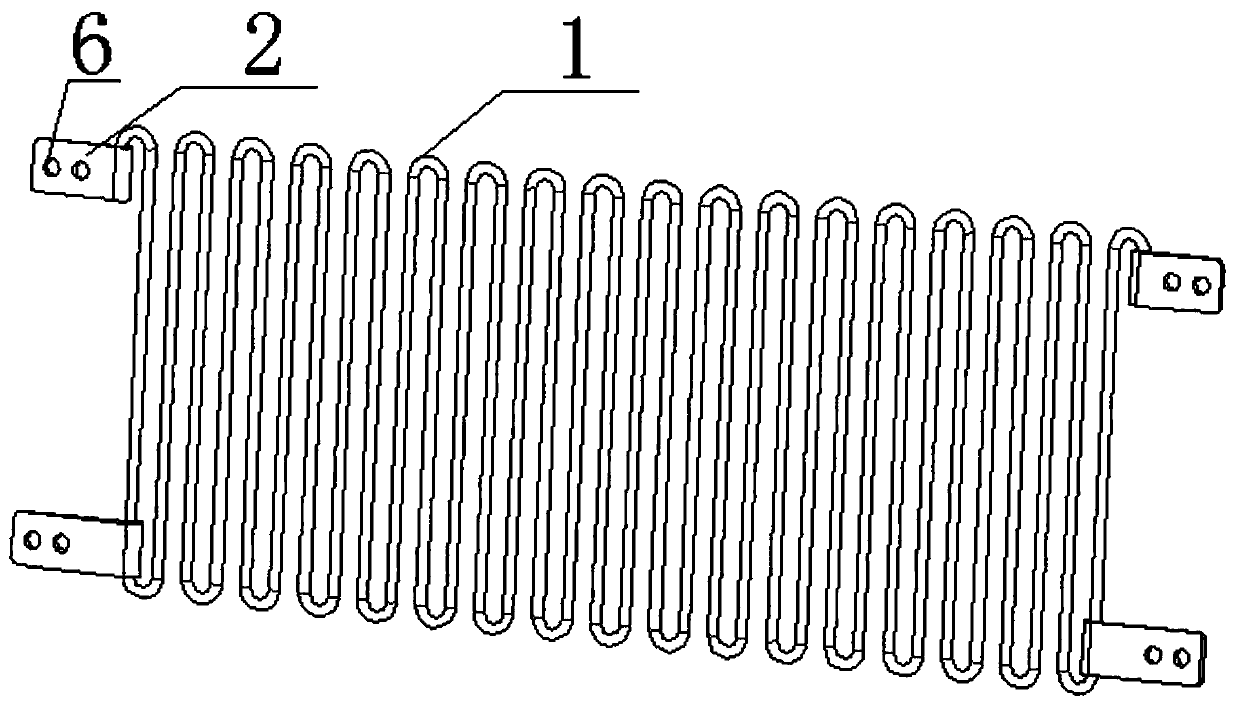

[0031] As shown in the figure, the high-voltage non-inductive resistor includes a plurality of "S"-shaped resistors 1, and the resistors 1 are made of Ni20Cr80 and have a resistivity of 1.10×10 -6 The hollow nickel-chromium alloy tube 101 of Ω·m is bent. The outer diameter of the hollow nickel-chromium alloy tube 101 is 3.0mm and the inner diameter is 1.5mm. Argon-arc welding at the joint, stainless steel frames 3 are arranged on both sides of the resistance sheet 1, the connecting plate frame 7 is fixedly installed on the stainless steel frame 3, and the corresponding mounting holes 6 are set at the corresponding positions of the stainless steel connector 2 and the connecting plate frame 7, and the stainless steel The connector 2 is connected to the corresponding connecting plate frame 7 through the bolt 8 and the nut installed in the mounting hole 6, and the resistance sheet 1 is combined in series and in parallel to form at least two upper and lower adjacent ones according t...

Embodiment 2

[0039] The high-voltage non-inductive resistor, the "S"-shaped resistor sheet 1 is made of Ni20Cr80 with a resistivity of 1.14×10 -6 The hollow nickel-chromium alloy tube 101 of Ω·m is bent, and the other structures are the same as those described in Embodiment 1.

[0040] The manufacturing method of the above-mentioned high-voltage non-inductive resistor is shown in the figure, and the steps are as follows:

[0041] 1. Bend the hollow nickel-chromium alloy tube 101 to make an "S"-shaped resistor 1 according to the micro-induction requirements;

[0042] 2. The resistance sheet 1 after bending and forming is solid-solution treated at 1150°C as a whole, and after 10 minutes of heat preservation, it is water-cooled to dissolve the carbides in the nickel-chromium alloy and obtain single-phase austenite, and then at 950°C for 3 hours. aging treatment;

[0043] 3. After heat treatment, the upper and lower ends of both sides of the resistance sheet 1 are argon-arc welded with the sta...

Embodiment 3

[0046] The high-voltage non-inductive resistor, the "S"-shaped resistor sheet 1 is made of Ni20Cr80 with a resistivity of 1.12×10 -6 The hollow nickel-chromium alloy tube 101 of Ω·m is bent, and the other structures are the same as those described in Embodiment 1.

[0047] The manufacturing method of the above-mentioned high-voltage non-inductive resistor is shown in the figure, and the steps are as follows:

[0048] 1. Bend the hollow nickel-chromium alloy tube 101 into an "S"-shaped resistor 1 according to the micro-induction requirements;

[0049] 2. The resistance sheet 1 after bending and forming is solid-solution treated at 1060°C as a whole, and after 15 minutes of heat preservation, it is water-cooled to dissolve the carbides in the nickel-chromium alloy and obtain single-phase austenite, and then at 920°C for 3 hours. aging treatment;

[0050] 3. After heat treatment, the upper and lower ends of both sides of the resistance sheet 1 are argon-arc welded with the stai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com