Gold catalyst as well as preparation method and application thereof

A gold catalyst and reaction technology, which is applied in the field of gold catalyst and its preparation, can solve the problems of raw material waste and waste gas, secondary pollution of waste gas, complex treatment process, etc., achieve reduction of waste gas and waste water generation, high raw material utilization rate, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a gold catalyst and a preparation method thereof, the preparation method comprising the following steps:

[0045] (1) the chloroauric acid solution is adjusted to an end point pH of 10 by pH to obtain an alkaline gold solution;

[0046] (2) CeO 2 After the carrier is mixed with the alkaline gold solution described in step (1), the pH is 10 and 25° C. for standing reaction for 18 days to obtain the supernatant and the gold catalyst; the obtained gold catalyst is dried at 60° C. for 4 hours; the obtained supernatant Liquid circulation is reused to step (1) as chloroauric acid solution;

[0047] Among them, CeO 2 The mass ratio of the carrier to the chloroauric acid in the chloroauric acid solution described in step (1) is 1:0.05.

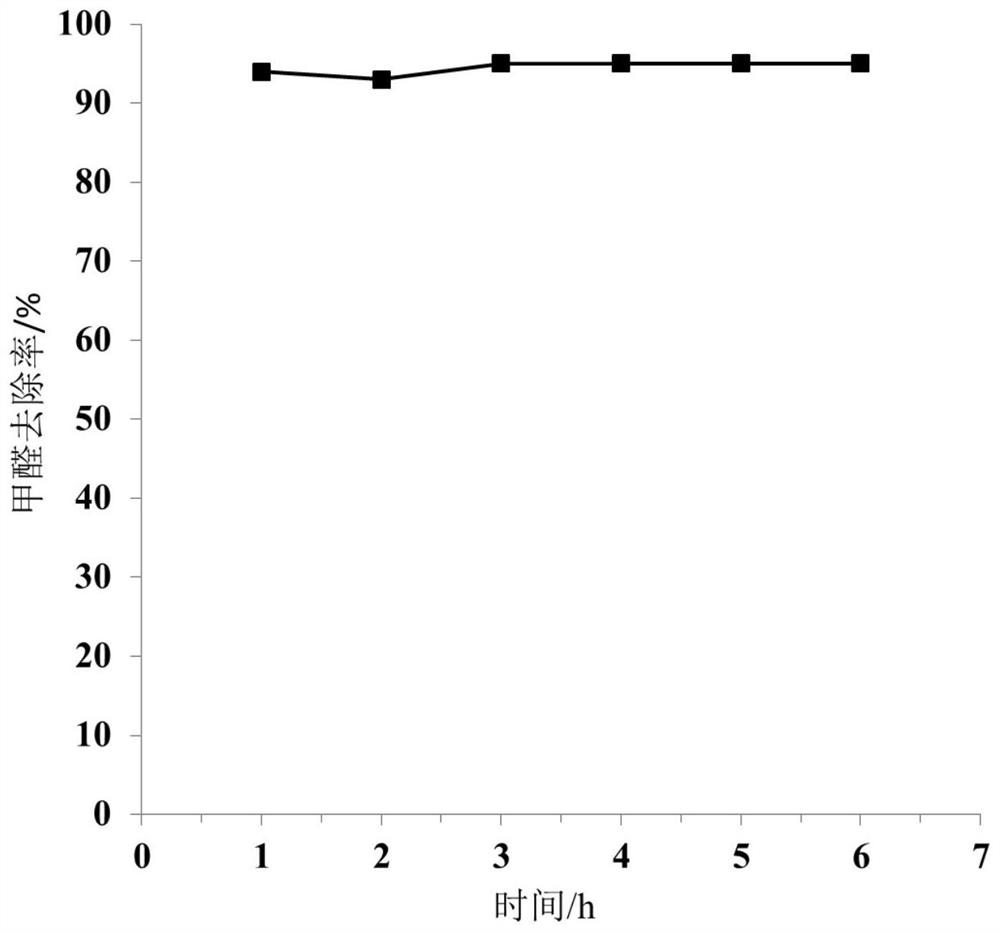

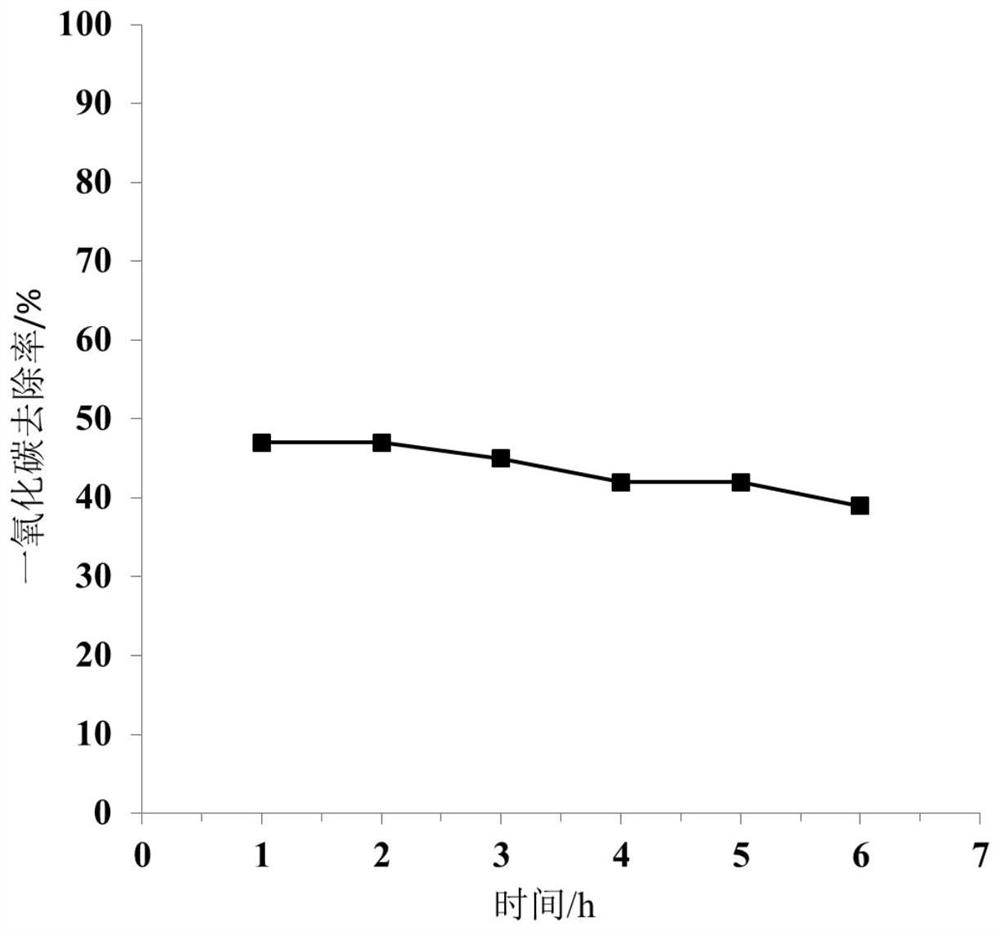

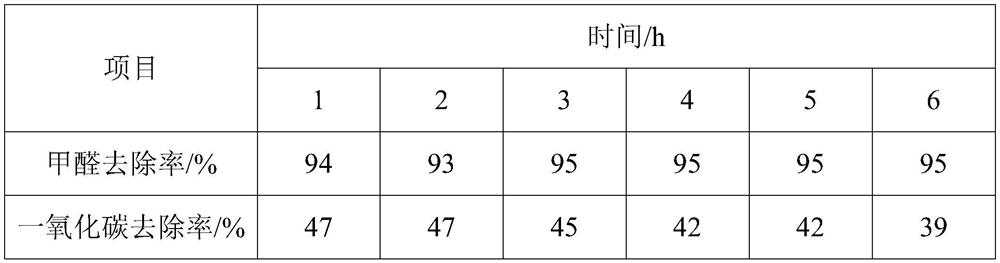

[0048] The gold catalyst obtained in this embodiment is tested for the removal rate of formaldehyde and carbon monoxide, and the test method is as follows:

[0049] Put 50mg gold catalyst in the fixed-bed quartz flo...

Embodiment 2

[0055] This embodiment provides a gold catalyst and a preparation method thereof, the preparation method comprising the following steps:

[0056] (1) the chloroauric acid solution is adjusted to an end point pH of 9 through pH adjustment to obtain an alkaline gold solution;

[0057] (2) TiO 2 After the carrier is mixed with the alkaline gold solution described in step (1), the reaction is left to stand at pH 9 and 30°C for 14 days to obtain the supernatant and the gold catalyst; the obtained gold catalyst is dried at 40°C for 8 hours; the obtained supernatant Liquid circulation is reused to step (1) as chloroauric acid solution;

[0058] Among them, TiO 2 The mass ratio of the carrier to the chloroauric acid in the chloroauric acid solution described in step (1) is 1:0.0002.

Embodiment 3

[0060] This embodiment provides a gold catalyst and a preparation method thereof, the preparation method comprising the following steps:

[0061] (1) the chloroauric acid solution is adjusted to an end point pH of 11 by pH to obtain an alkaline gold solution;

[0062] (2) Al 2 o 3 After the carrier is mixed with the alkaline gold solution described in step (1), the reaction is left to stand at pH 8 and 20°C for 20 days to obtain the supernatant and the gold catalyst; the obtained gold catalyst is dried at 50°C for 6 hours; the obtained supernatant Liquid circulation is reused to step (1) as chloroauric acid solution;

[0063] Among them, Al 2 o 3 The mass ratio of the carrier to the chloroauric acid in the chloroauric acid solution described in step (1) is 1:0.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com