Dust-free sterilization and disinfection device

A sterilization and disinfection device and technology for sterilization and disinfection, applied in disinfection, water supply devices, sanitary equipment for toilets, etc., can solve the problems of limited ozone volume, high cost, increased pollution risks, etc., to reduce the workload of personnel and reduce personnel. Intervention and improvement of the effect of sterilization and disinfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

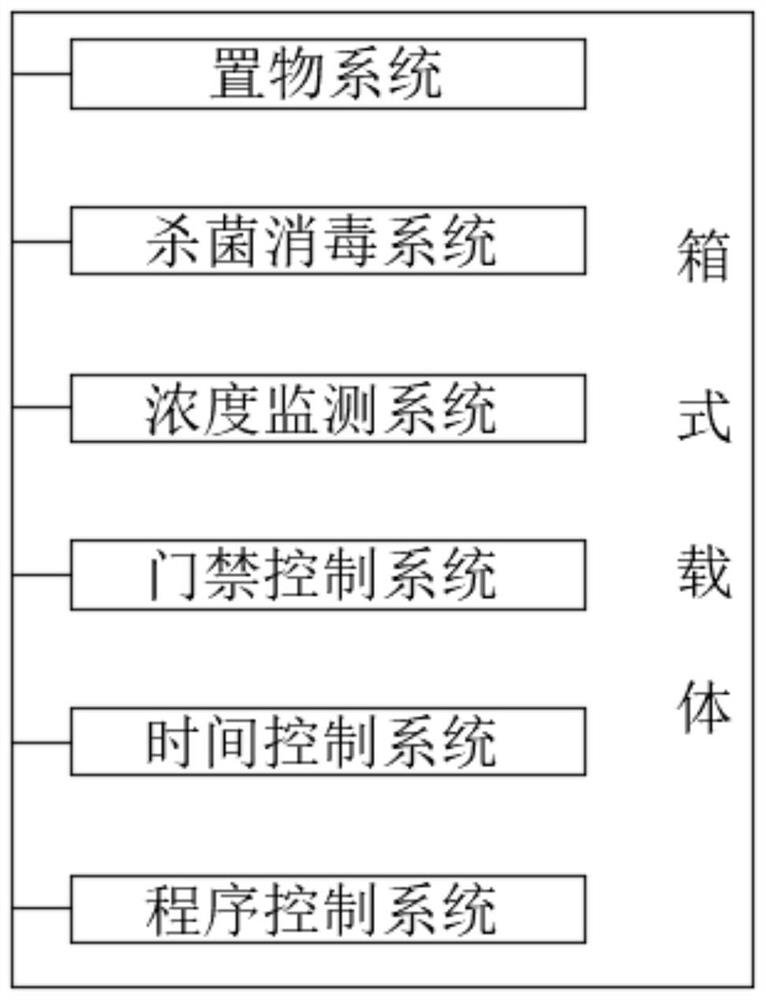

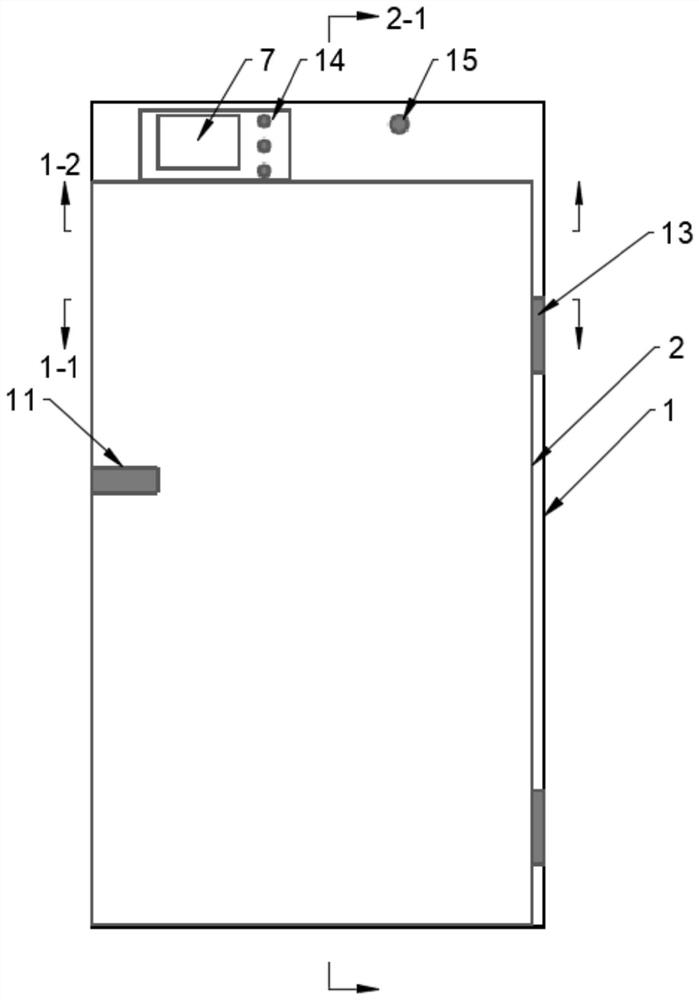

[0056] Such as Picture 1-1 As shown, this application highlights a dust-free sterilization and disinfection device, including a box-type carrier, on which a storage system, a sterilization and disinfection system, a concentration monitoring system, an access control system and a time control system are installed, wherein,

[0057] The box-type carrier is a double-layer box-type structure, consisting of two boxes inside and outside. The inner box is seamlessly welded on the inner bottom surface of the outer box. It is welded with a stainless steel frame, and the frame is sealed with a sealing material. The box-type carrier is used to install the electronic equipment of the equipment system, sterilization and disinfection system, concentration monitoring system, access control system and time control system, etc.

[0058] The storage system is used to place items to be sterilized;

[0059] The present invention is used for ozone sterilization inside the box, so a storage system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com