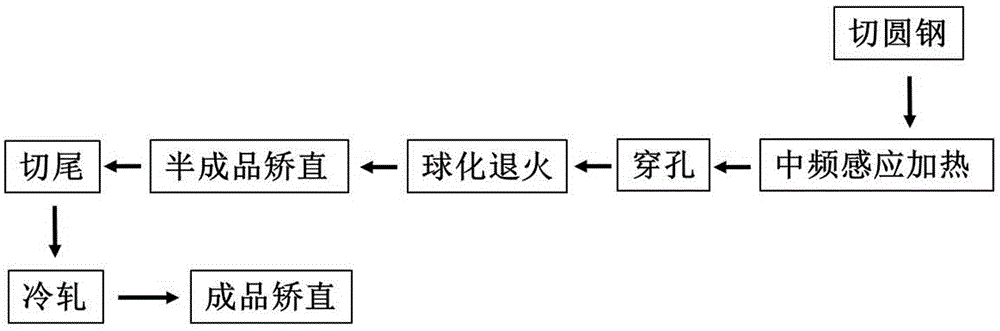

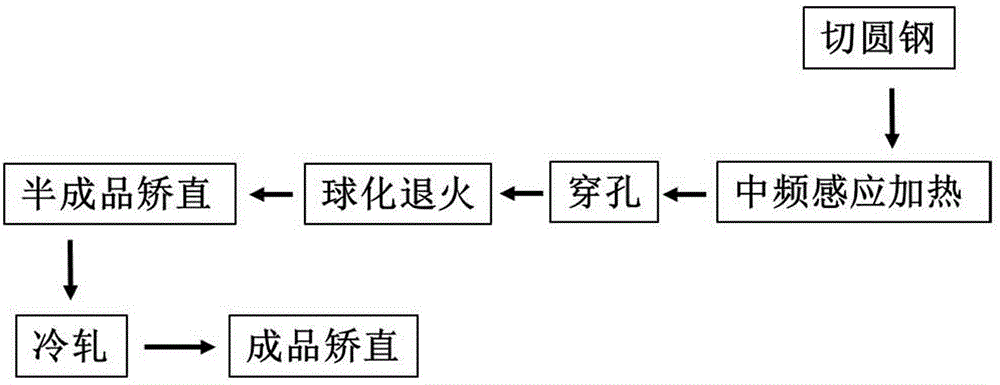

Cold-rolled steel tube tail-cropping-free production technology

A production process and steel pipe technology, applied in the direction of metal rolling, etc., can solve the problems of increased production cycle and production cost, failure to pass the cold-rolled mandrel head, and cold-rolled production cannot be carried out smoothly, so as to improve production efficiency and save production Cost, reduction of production cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: A cold-rolled steel pipe cutting-free production process, using MCK40 intermediate frequency furnace to process round steel with a diameter of 50mm, the length of the steel pipe is 1166mm, the underheating temperature is set to ≤1035°C, and the overheating temperature is set to ≥ 1090°C, heating power is 552kw, feed time is 240s, steel pipe tail shrinkage is 2mm.

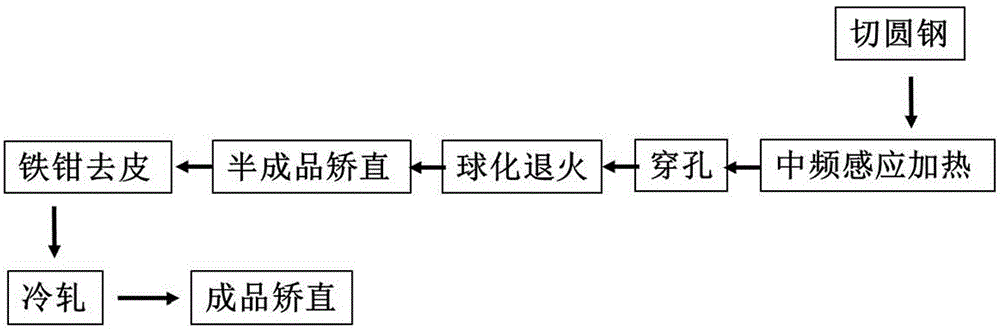

[0035] Use iron tongs to remove the iron sheet attached to the tail of the waste pipe instead of the tail cutting process.

Embodiment 2

[0036] Example 2: A cold-rolled steel pipe cutting-free production process, the cold-rolled mandrel mold is improved to reduce the diameter of the big end of the rolled mandrel by 1 mm, and the MCK40 intermediate frequency furnace is used to process round steel with a diameter of 45 mm. The length of the steel pipe is 800mm, the underheating temperature is set to ≤1035°C, the overheating temperature is set to ≥1090°C, the heating power is 465kw, the feeding time is 240s, and the tail shrinkage of the steel pipe is 2.2mm.

Embodiment 3

[0037] Example 3: A production process of cold-rolled steel pipe without tail cutting, using MCK50 intermediate frequency furnace to process round steel with a diameter of 70mm, the length of the steel pipe is 700mm, the underheating temperature is set to ≤1035°C, and the overheating temperature is set to ≥ 1090°C, heating power is 680kw, feeding time is 336s, steel pipe tail shrinkage is 1.5mm.

[0038] Use iron tongs to remove the iron sheet attached to the tail of the waste pipe instead of the tail cutting process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com