Layered product for soft packaging, soft packaging material, and soft package

A technology of flexible packaging and laminates, which is applied in packaging, wrapping paper, transportation and packaging, etc. It can solve the problems of large gaps, water resistance, poor puncture strength and gas barrier properties, and achieve excellent pinhole resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

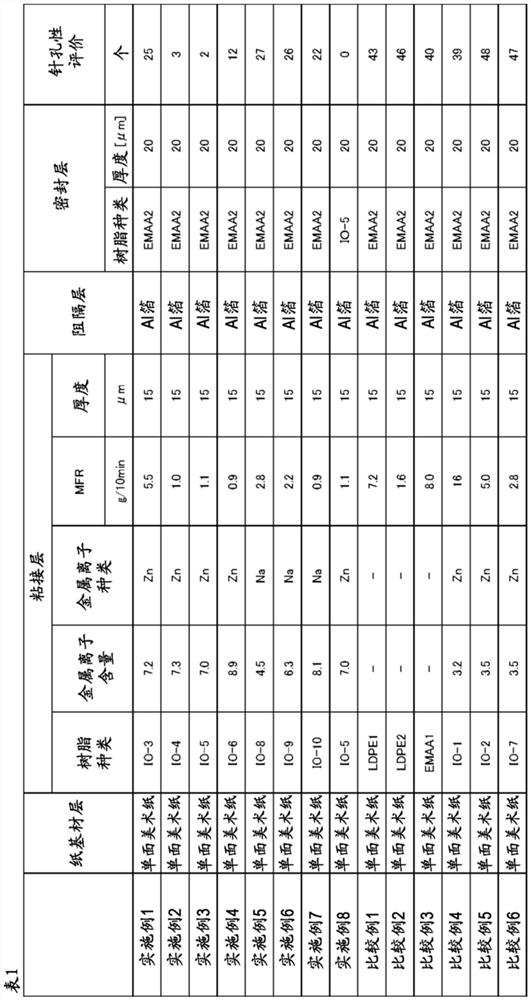

Embodiment 1~7、 comparative example 1~6

[0143] Using an extrusion laminator with a 65mmΦ extruder (L / D=28), under the processing conditions of a die temperature of 300°C, a gap of 110mm, and a processing speed of 80m / min, the paper substrate layer was implemented on-line. After corona treatment, the ionomer (A) of ethylene-unsaturated carboxylic acid copolymer, low-density polyethylene, or ethylene-unsaturated carboxylic acid copolymer is extrusion-coated between the paper substrate layer and the barrier layer , thereby obtaining a laminate in which the paper base layer, the adhesive layer, and the barrier layer are laminated in this order.

[0144]Further, using an extrusion laminator with a 65mmΦ extruder (L / D=28), under the processing conditions that the under-die temperature is 285°C, the gap is 110mm, and the processing speed is 80m / min, in the above-mentioned manner The Al foil of the obtained laminate was extrusion-coated with an ethylene-unsaturated carboxylic acid copolymer or an ionomer of an ethylene-unsa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com