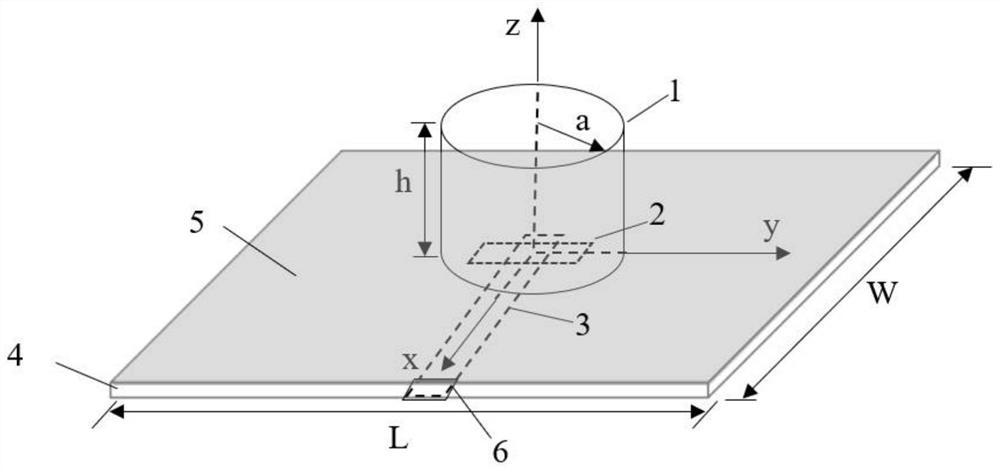

Preparation method of magnetic dielectric composite material dielectric resonator and miniaturized antenna

A technology of dielectric resonators and composite materials, applied in resonators, antenna grounding switch structure connection, circuits, etc., can solve the problems of antenna efficiency reduction, gain reduction, high magnetic and dielectric loss, etc., to improve performance, expand bandwidth, The effect of reducing the size of the antenna

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] A method for preparing a dielectric resonator made of magnetic and dielectric composite materials according to the present invention is specifically implemented according to the following steps:

[0054] Step 1, adopt solid-phase method to prepare Ba 3 co 2 Fe 24 o 41 Powder; specifically:

[0055] Step 1.1, will analyze the pure grade 99% BaCO 3 powder, CoO powder, Fe 2 o 3 The powder is put into a polytetrafluoroethylene ball mill jar, and absolute ethanol and zirconia beads are added to the polytetrafluoroethylene ball mill jar for ball milling. The ball milling time is 4h to 8h, and then dried at 80°C to obtain a solid mixture;

[0056] Step 1.2, sintering the solid mixture obtained after step 1.1 to obtain a sintered powder;

[0057] The sintering process is as follows: first raise the temperature to 1000°C at a rate of 5°C / min for 2 hours, then raise the temperature to 1250°C at a rate of 3°C / min and hold for 4 hours, then cool to room temperature;

[0058...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com