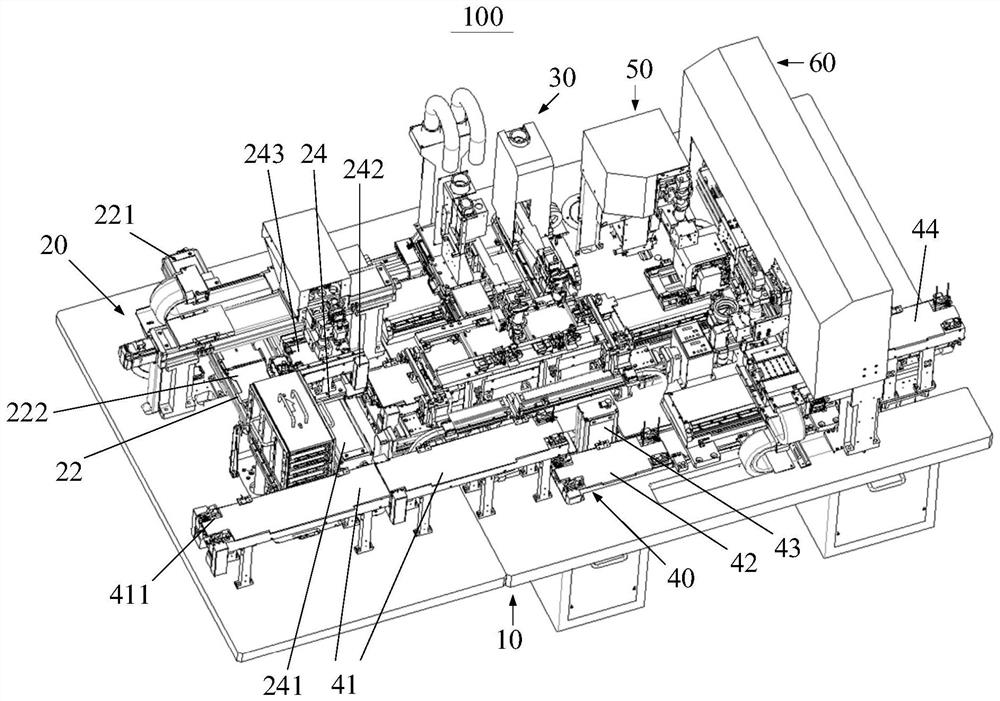

Chip laminating equipment

A technology for laminating equipment and chips, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of high cost, low production efficiency, low pass rate of chip attachment, etc., achieve high productivity, improve efficiency, Avoid the effect of excessive attachment force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

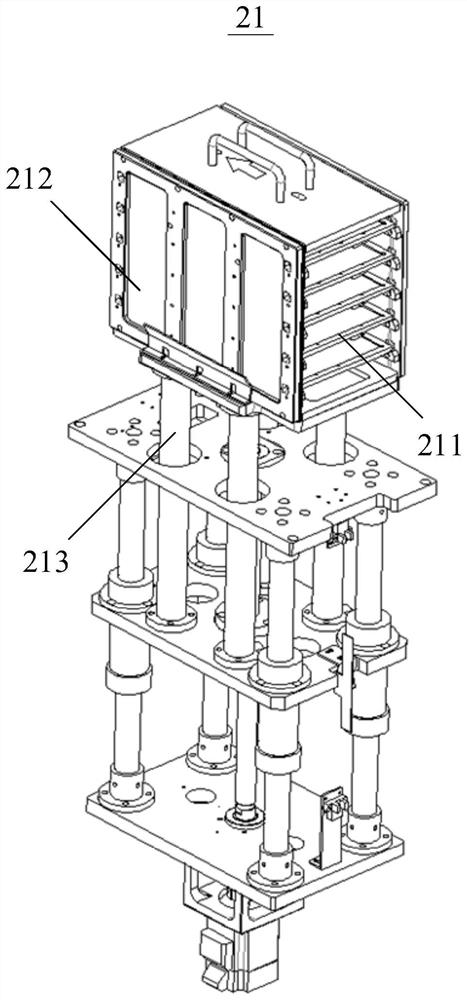

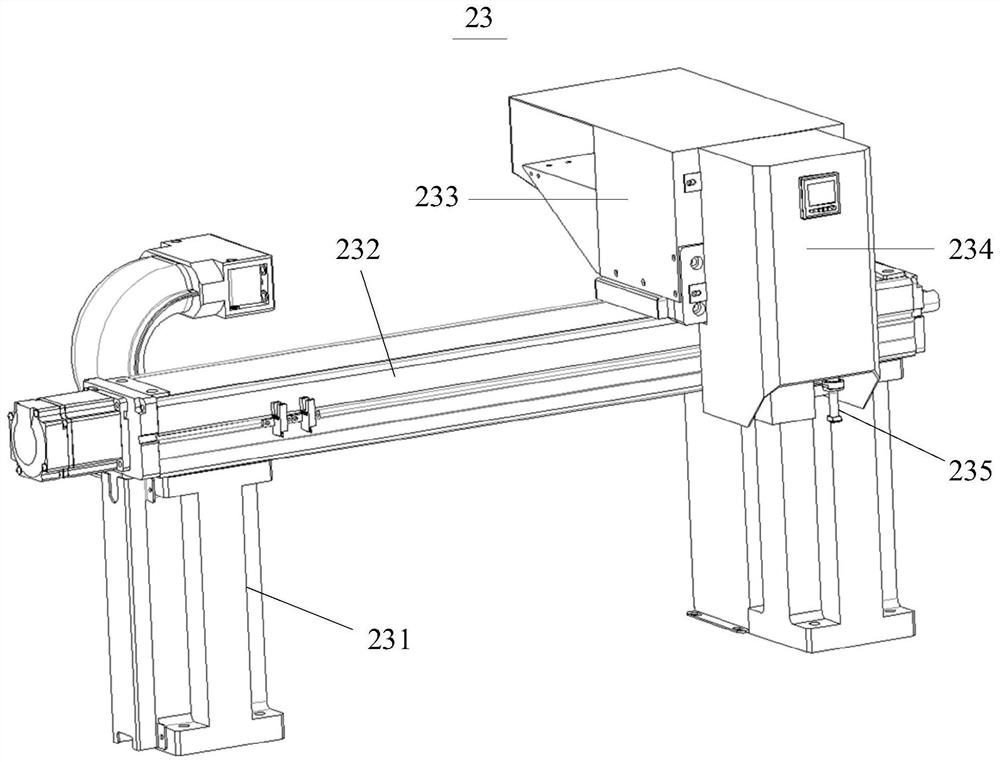

[0043] In order to facilitate understanding of the present application, the present application will be further described below with reference to the related drawings. The preferred embodiment of the present application is given. However, the present application can be implemented in many different forms, is not limited to the embodiments described herein. Conversely, the purpose of providing these embodiments is to make it more thoroughly comprehensively understood the disclosure of the present application.

[0044] The description of the following examples is illustrated with reference to the present invention, and a particular embodiment of the application can be implemented. In this paper, the serial number of the component itself, such as "first", "second", etc., only for distinguishing the described object, does not have any order or technical meaning. The "Connect", "join", including direct and indirect connections (coupled), as specifically described. The direction term me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com