Propeller blade self-adaptive measuring point planning method based on T-spline

A propeller blade and self-adaptive measurement technology, applied in prediction, data processing application, calculation, etc., can solve the problems of poor surface description accuracy and low adaptability of measurement points, and achieve high accuracy and timeliness of adaptive interpolation approximation position High, improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

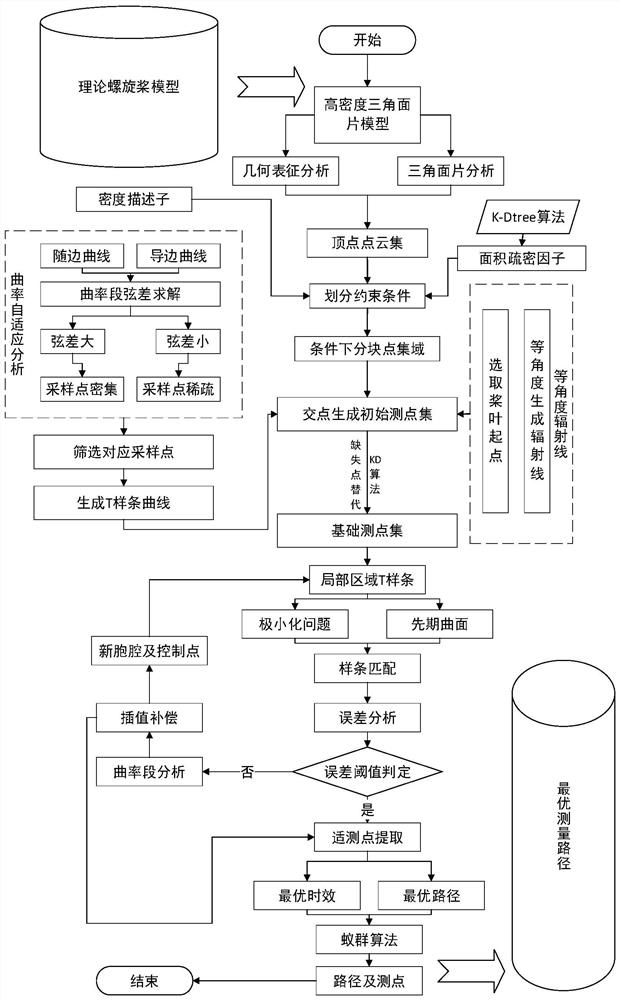

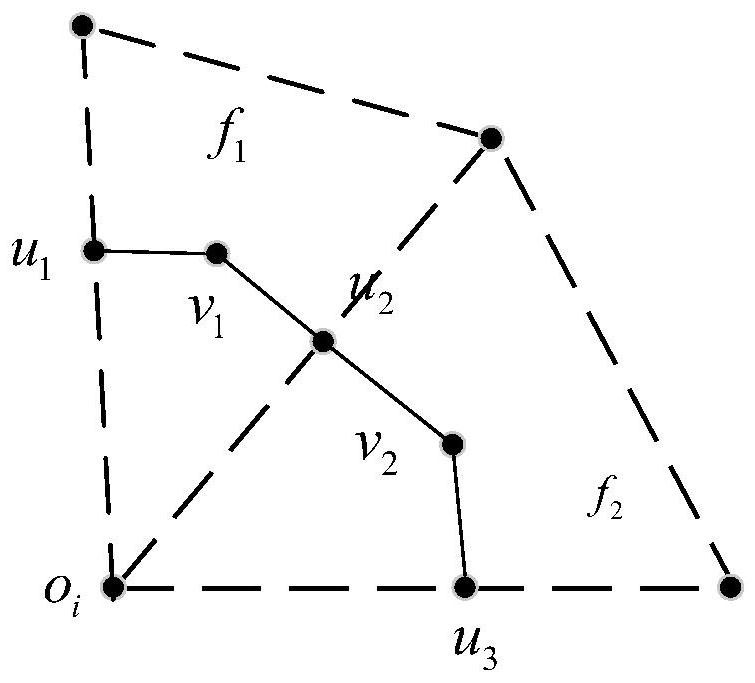

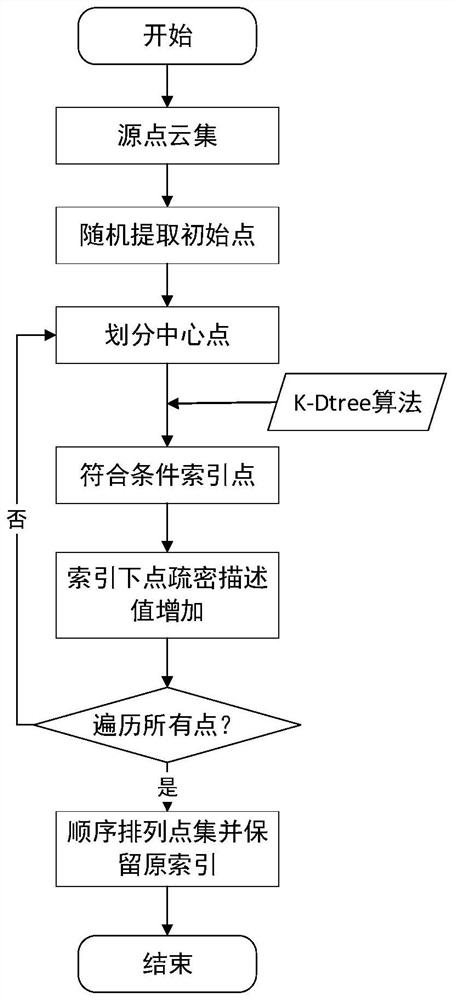

[0073] like figure 1 As shown, the present invention provides a T-spline-based propeller blade self-adaptive measurement point planning method. First, a coordinate system is established to extract the triangular patch vertex set through the 3D CAD model of the propeller blade, and the density area factor is adaptively generated; the radius K-Dtree search algorithm is used to sort the density descriptor and retain the original index; the density factor and the dense descriptor are integrated , divide the point sets of equal-constrained regions; construct the previous T-spline surface according to the division of the point set domain; generate the T-spline surface curve adaptively by curvature, and generate the initial measuring point set by combining the radial line of the equal-angle blade; the nearest point lacks replacement, and the base is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com