Smart factory management system

A factory management and smart technology, applied in the direction of comprehensive factory control, comprehensive factory control, general control system, etc., can solve the problems of lack of product storage management, lack of internal transportation management, unable to allocate personnel, etc., to prevent messy stacking, Manage and ensure the effectiveness of the storage environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

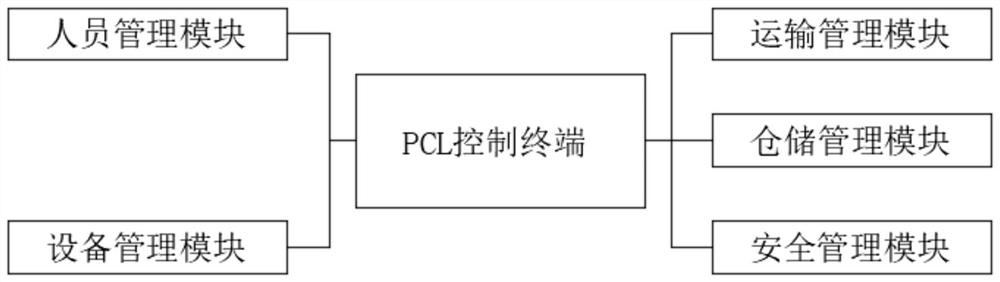

[0046] see Figure 1~4 , a smart factory management system, including

[0047] PCL control terminal, which constitutes the control center of the management system, and is used to receive the transmission signals of each module and issue corresponding control instructions to each module;

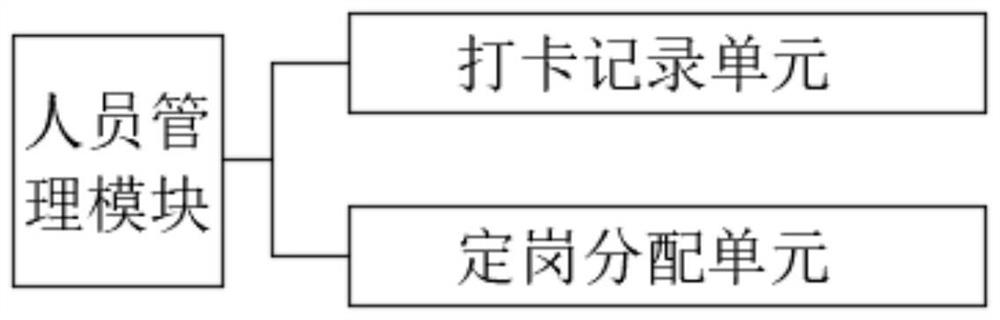

[0048] A personnel management module, which is connected to the PCL control terminal for signal transmission, and which performs statistics and deployment of employees in the factory;

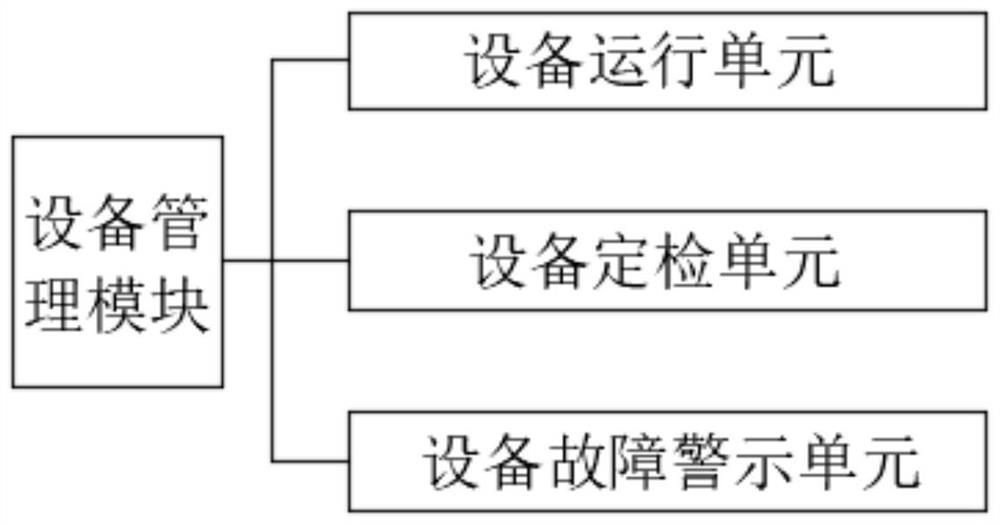

[0049] An equipment management module, which performs signal transmission connection with the PCL control terminal, and supervises each production line and equipment of the factory;

[0050] The transportation management module is connected with the PCL control terminal for signal transmission, and it supervises the transportation process of the processed products.

[0051] In the embodiment of the present invention, the personnel management module is composed of a clock-in record unit and a post assignment ...

Embodiment 2

[0064] see Figure 1~6 , a smart factory management system, including

[0065] PCL control terminal, which constitutes the control center of the management system, and is used to receive the transmission signals of each module and issue corresponding control instructions to each module;

[0066] A warehouse management module, which is connected to the PCL control terminal for signal transmission, and which supervises the storage of processed products;

[0067] The safety management module is connected with the PCL control terminal for signal transmission, and it performs safety management and control of the personnel and equipment of the factory.

[0068] In the embodiment of the present invention, the warehouse management module is composed of a classification and distinction unit and a temperature and humidity monitoring unit, and it includes the following steps:

[0069] ①The warehouse is divided into multiple areas by the classification and distinction unit of the wareho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com