A method for recovering low-temperature waste heat from cooling circulating water in a sugar factory

A technology for cooling circulating water and low-temperature waste heat, which is applied in sucrose production, sugar production, and sugar solution boiling/evaporation. The effect of high energy efficiency ratio and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

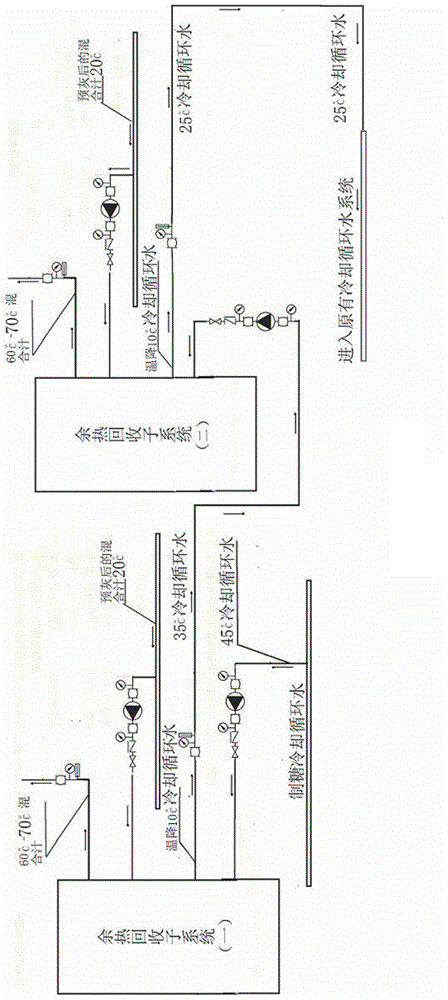

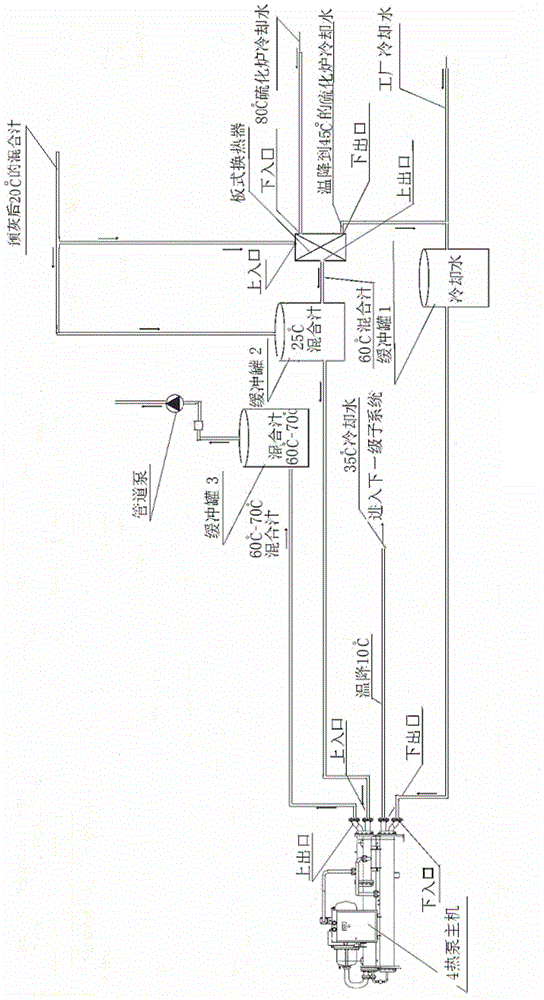

Method used

Image

Examples

Embodiment

[0026] Calculation of benefits in units of 10,000 tons of sugarcane crushed per day

[0027] The amount of cooling water produced by pressing 10,000 tons of sugarcane per day is 8,000 tons / hour and the temperature is 45°C. If the present invention is used to extract heat at 20°C for recovery, the total recoverable energy is 186,000 kW / h. Equivalent to the energy of 66.9 tons / hour of standard coal (according to the national standard of 1 kW / 0.36 kg / hour), if the temperature of the circulating water in the condenser of the evaporation tank is lowered to about 25°C by using the present invention, the evaporation time will be shortened, and the quality will be improved. improved. It can be seen that the use of this system can not only obtain considerable economic benefits, but also obtain social benefits of energy saving and environmental protection.

[0028] The present invention recycles the low-temperature waste heat in the hot water with the water outlet temperature of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com