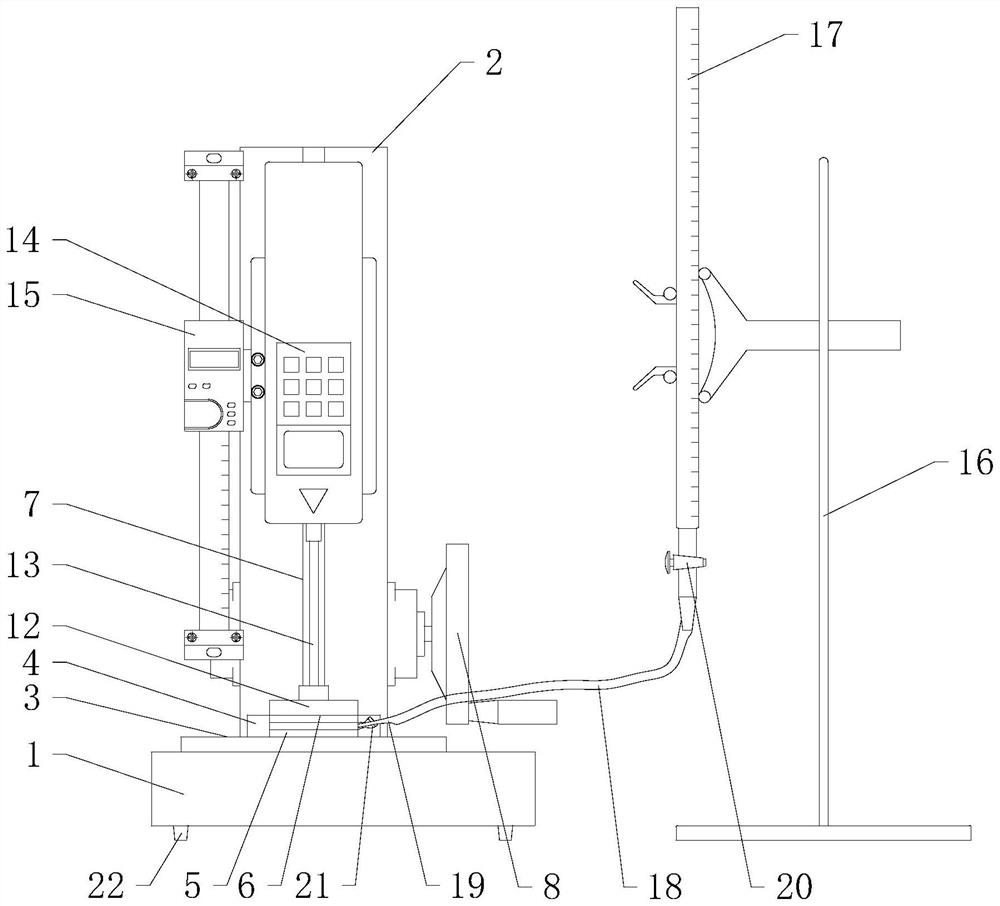

Device and method for testing wet-state springback capability of AGM partition plate under different compression amounts

A technology of ability testing and compression, applied in measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve problems such as detection methods and technical indicators that are not clearly specified.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

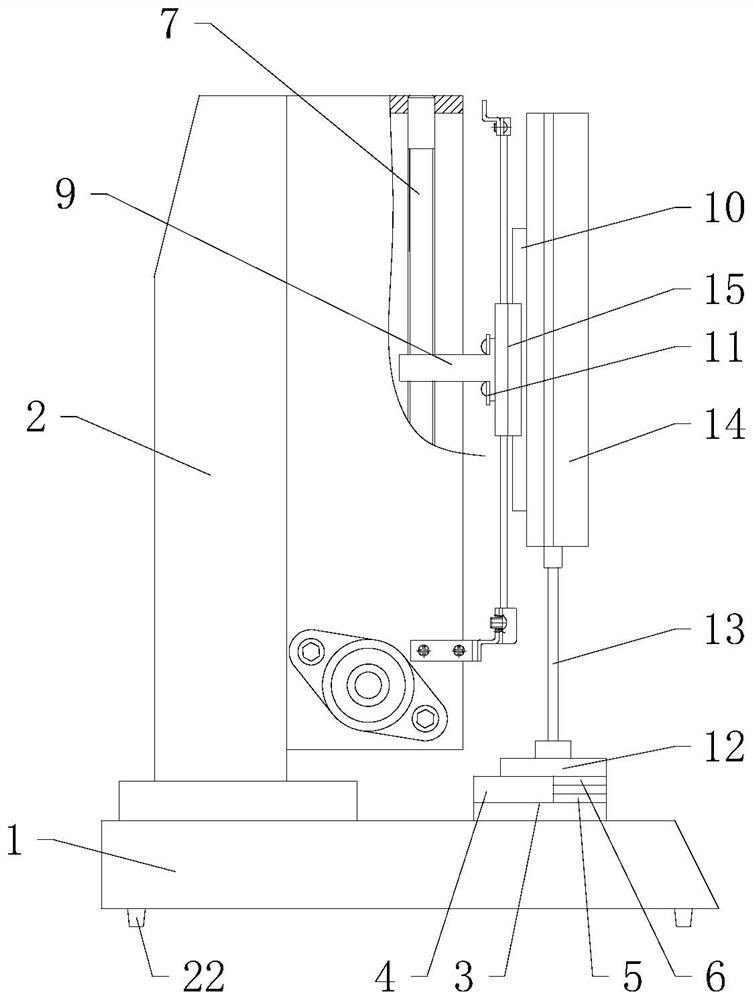

Method used

Image

Examples

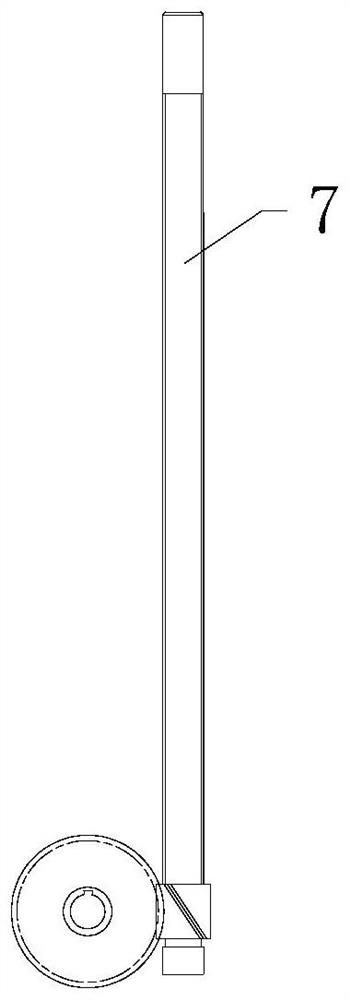

Embodiment 1

[0060] Cut the AGM separator samples with a diameter of Φ60mm. The samples with a thickness of less than 1.5mm are grouped with 5 pieces, and the samples with a thickness greater than or equal to 1.5mm are grouped with 4 pieces. Cut 3 groups for use; The AGM separator samples in the first group are perforated first, and the holes are evenly perforated on the end surface of the entire sample. The interval between adjacent holes is not greater than 2mm, and the hole diameter is not greater than 0.2mm. When piercing, the above-mentioned AGM separator can be used to test the wet rebound ability under different compressions, and multiple sets of steel needles are evenly installed on the pressure-applying end, and the lifting assembly is used to complete the piercing operation of the sample. Afterwards, use a drying room to dry at 105±2°C for more than 1 hour. During the drying process, the drying room should maintain a negative pressure state, and finally take it out to the cooling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com