Shrinkage sintering inhibition for improving electrode continuity of multilayer ceramic assembly

A continuity and electrode technology, which is applied in the field of shrinkage suppression and sintering to improve the electrode continuity of laminated ceramic components, can solve the problems of capacitance attenuation, poor electrical quality, and functional damage, etc. Continuity problem, effect of good electrode continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

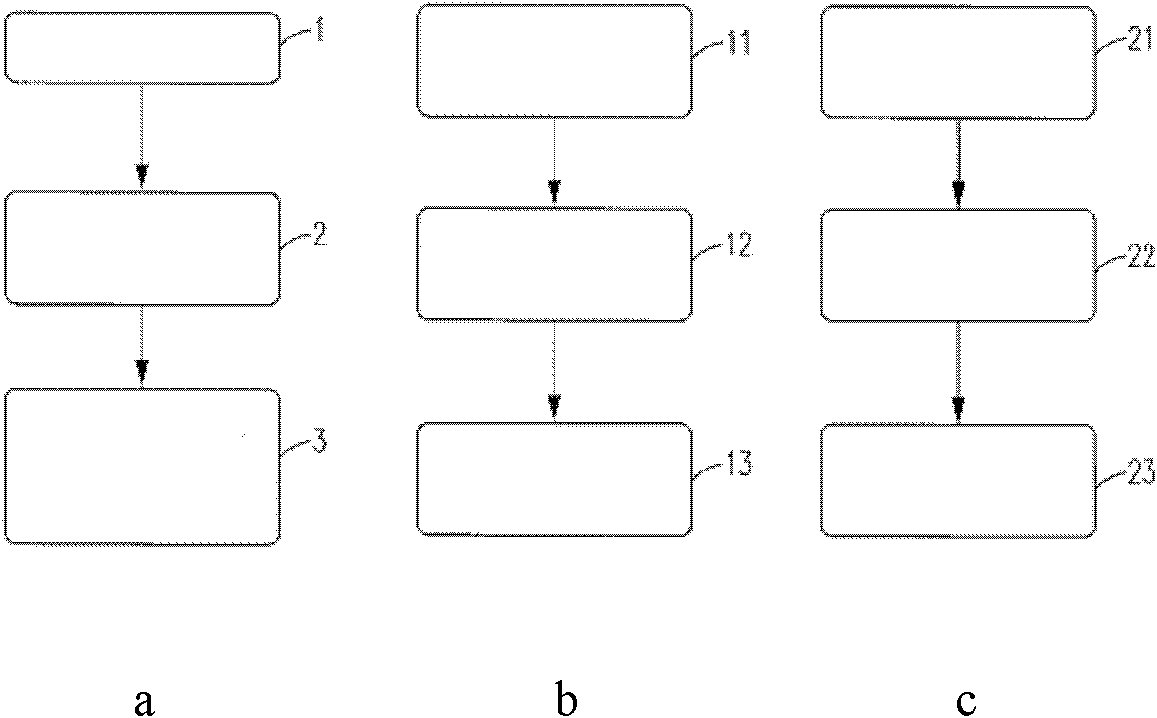

[0070] See figure 1 a, the present invention provides a sintering method, which includes the steps of: providing a first green body 1, forming a second green body 2 on the first green body, and simultaneously heating the first green body and the second green body to a specific temperature 3 , wherein the specific temperature enables complete sintering 4 of the first green body. In a preferred embodiment of the present invention, the specific temperature may be above 600-2000° C., and the sintering temperature of the second green body needs to be higher than the specific temperature. In addition, the first green body has a shrinkage amount, and shrinkage of the shrinkage amount is suppressed by the second green body. The first green body can be formed by alternately stacking multiple ceramic green bodies and multiple electrode green bodies.

[0071] See figure 1 b. According to the inventive spirit of the present invention, it can also be used to provide another sintering me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com