Photoanodic film and its preparation method and application

A technology of photoanode and hydrothermal reaction, which is applied in the direction of metal material coating process, coating, liquid chemical plating, etc., can solve the problems of poor metal anti-corrosion effect, improve durability, expand light absorption and utilization efficiency, improve The effect of antiseptic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

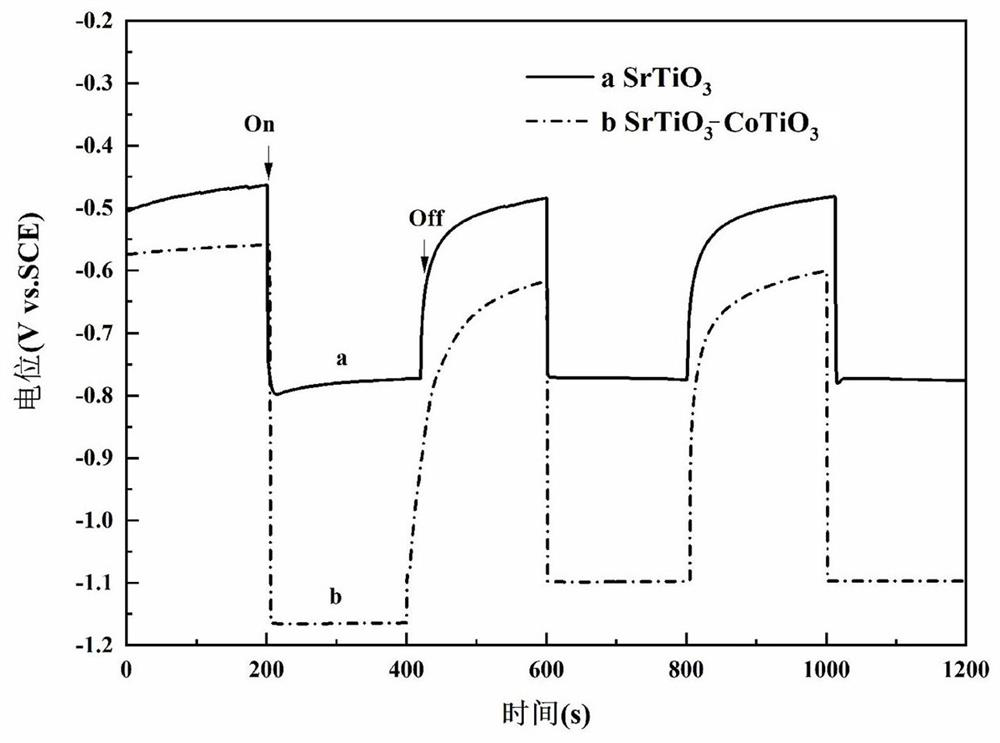

[0043] The present invention also provides a SrTiO 3 -CoTiO 3 The preparation method of the photoanode film adopts the following technical scheme: comprising the following steps: (1) pretreating the conductive glass; (2) placing the conductive surface of the conductive glass obtained after the pretreatment in step (1) downward. In a mixed solution containing strontium salt, cobalt salt and tetrabutyl titanate, a hydrothermal reaction is carried out to obtain SrTiO deposited on the surface. 3 -CoTiO 3 (3) calcining the product obtained by the treatment in step (2) to obtain the SrTiO 3 -CoTiO 3 Photo-anodized film.

[0044] The present invention also provides SrTiO as described above 3 -CoTiO 3 The application of the photoanode film, which adopts the following technical scheme: the above-mentioned SrTiO 3 -CoTiO 3 Application of photoanodic film in anticorrosion of steel reinforcement in marine construction engineering.

Embodiment 1

[0047] 1. SrTiO of this embodiment 3 -CoTiO 3 The photoanode film is prepared according to the following method, comprising the following steps:

[0048] (1) Pretreatment of conductive glass: Put the FTO conductive glass into a beaker containing detergent-containing aqueous solution, NaOH ethanol solution, ethanol and deionized water in sequence, and ultrasonically clean them for 15 minutes respectively, and clean them (during the hydrothermal reaction) Before, the FTO conductive glass needs to be thoroughly cleaned, the purpose is to improve the adhesion between the film and the glass);

[0049] (2) Add strontium nitrate, cobalt nitrate and tetrabutyl titanate to the water, stir evenly, then add N-polyvinylpyrrolidone (PVP), continue to stir until dissolved, and prepare a solution containing 0.05mmolL -1 Strontium nitrate, 0.05mmolL -1 Cobalt nitrate, 0.1mmolL -1 A mixed solution of tetrabutyl titanate and 10 mmol of N-polyvinylpyrrolidone (PVP), and the above mixed sol...

Embodiment 2

[0058] 1. SrTiO of this embodiment 3 -CoTiO 3 The photoanode film is prepared according to the following method, comprising the following steps:

[0059] (1) Pretreatment of conductive glass: Put the FTO conductive glass into a beaker containing detergent-containing aqueous solution, NaOH ethanol solution, ethanol and deionized water in sequence, and ultrasonically clean it for 15 minutes to clean it;

[0060] (2) Add strontium acetate, cobalt acetate and tetrabutyl titanate to the water, stir evenly, then add sodium dodecyl sulfate, continue to stir until dissolved, and prepare a solution containing 2.0 mmolL -1 Strontium acetate, 2.0mmolL -1 Cobalt acetate, 4mmolL -1 A mixed solution of tetrabutyl titanate and 16 mmol of sodium dodecyl sulfate, and poured the above mixed solution into the reaction kettle; then added the conductive surface of the FTO conductive glass pretreated in step (1) into the above mixed solution In the reaction, after 12h reaction at 150°C, coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com