High-temperature-resistant emulsion type acid liquor thickening agent and preparation method thereof

An acid thickener and emulsion type technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as inability to meet construction requirements, achieve convenient and fast on-site construction, good stability, and improve temperature resistance Effect of Shear Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

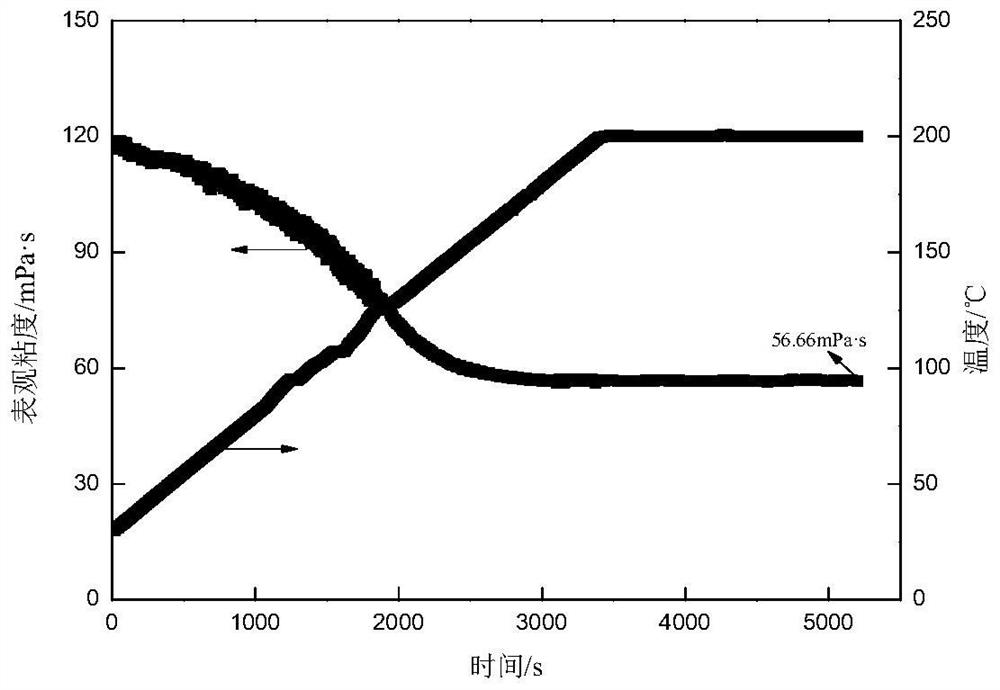

Examples

Embodiment 1

[0036] A preparation method of a high temperature resistant emulsion type acid thickener, comprising the following steps:

[0037] S1: Mix 6 parts of acrylamide (AM), 12 parts of methacryloylpropyl trimethyl ammonium chloride (MAPTAC), 9 parts of dimethyl diallyl ammonium chloride (DMDAAC), 3 parts of N-ethylene Nylpyrrolidone (NVP), 2 parts of tert-butyl hydroperoxide and 2 parts of sodium formate are added to 30 parts of deionized water under the action of magnetic stirring, until the substances are completely dissolved to obtain a mixed solution, and the concentration used is 20-30% Hydroxide Sodium adjustment adjusts the pH value of the mixed solution to 6, and keeps the temperature of the mixed solution below 30°C. After adjusting, cool to room temperature to obtain an aqueous phase solution;

[0038] S2: Mix 1 part of Span-80, 0.5 part of Span-83, 0.5 part of Tween-80, a total of 2 parts of emulsifier and 30 parts of white oil under the action of magnetic stirring to ob...

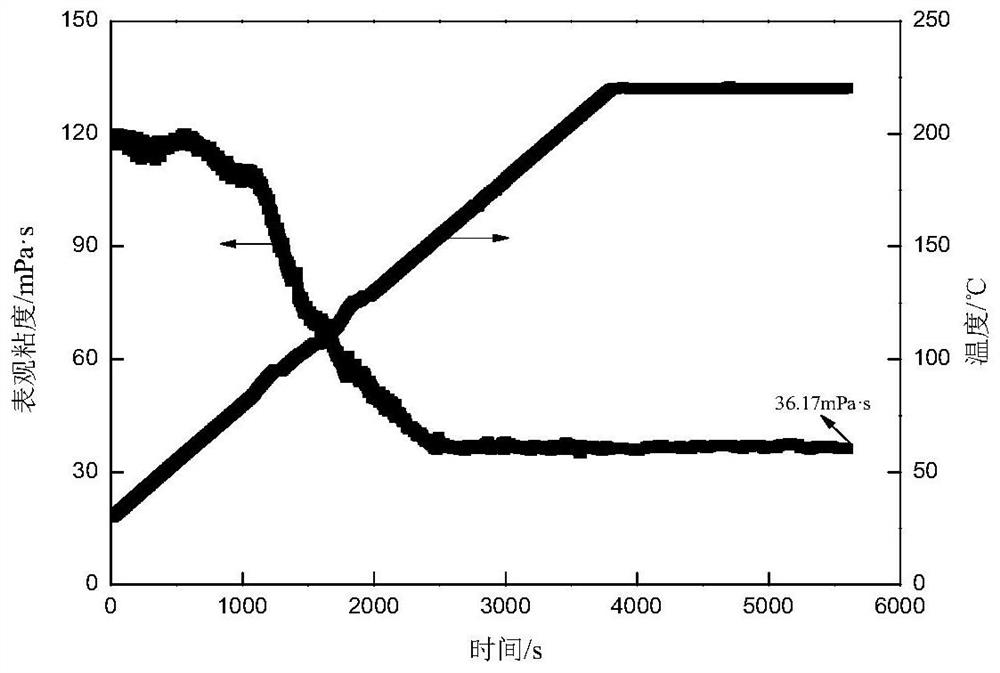

Embodiment 2

[0043] A preparation method of a high temperature resistant emulsion type acid thickener, comprising the following steps:

[0044]S1: Mix 6 parts of acrylamide (AM), 12 parts of methacryloylpropyl trimethyl ammonium chloride (MAPTAC), 9 parts of dimethyl diallyl ammonium chloride (DMDAAC), 3 parts of N-ethylene Nylpyrrolidone (NVP), 1 part of potassium persulfate and 1.5 parts of dodecyl mercaptan were added to 30 parts of deionized water under the action of magnetic stirring until the substances were completely dissolved to obtain a mixed solution with a concentration of 20 to 30%. Sodium hydroxide is adjusted to adjust the pH value of the mixed solution to 5, and the temperature of the mixed solution is always kept below 30°C. After adjusting, cool to room temperature to obtain an aqueous phase solution;

[0045] S2: Mix 1.75 parts of Span-80, 0.875 parts of Span-83, 0.875 parts of OP-10, a total of 3.5 parts of emulsifier and 30 parts of cyclohexane under the action of mag...

Embodiment 3

[0050] A preparation method of a high temperature resistant emulsion type acid thickener, comprising the following steps:

[0051] S1: Mix 4 parts of acrylamide (AM), 8 parts of methacryloylpropyl trimethyl ammonium chloride (MAPTAC), 6 parts of dimethyl diallyl ammonium chloride (DMDAAC), 2 parts of N-ethylene Nylpyrrolidone (NVP), 1 part of potassium persulfate and 1 part of isopropanol are added into 50 parts of deionized water under the effect of magnetic stirring, until the substance is completely dissolved to obtain a mixed solution, and the use concentration is 25% sodium hydroxide for adjustment The pH value of the mixed solution is up to 4, and the temperature of the mixed solution is kept below 30°C all the time. After adjusting, cool to room temperature to obtain an aqueous phase solution;

[0052] S2: Mix 2 parts of Span-80, 1 part of Span-83, 1 part of TX-15, a total of 4 parts of emulsifier and 20 parts of isoparaffin IsoparM under the action of magnetic stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com