Unpowered aerobic fermentation method for solid waste biomass container

A technology of aerobic fermentation and solid waste, applied in the field of microbial fermentation, can solve the problems of slow water loss, high operating cost, uneven material fermentation, etc., and achieve the effect of full utilization and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A stacked high fermentation container, including 4 container units, the container unit includes a box module and a ventilation module, wherein:

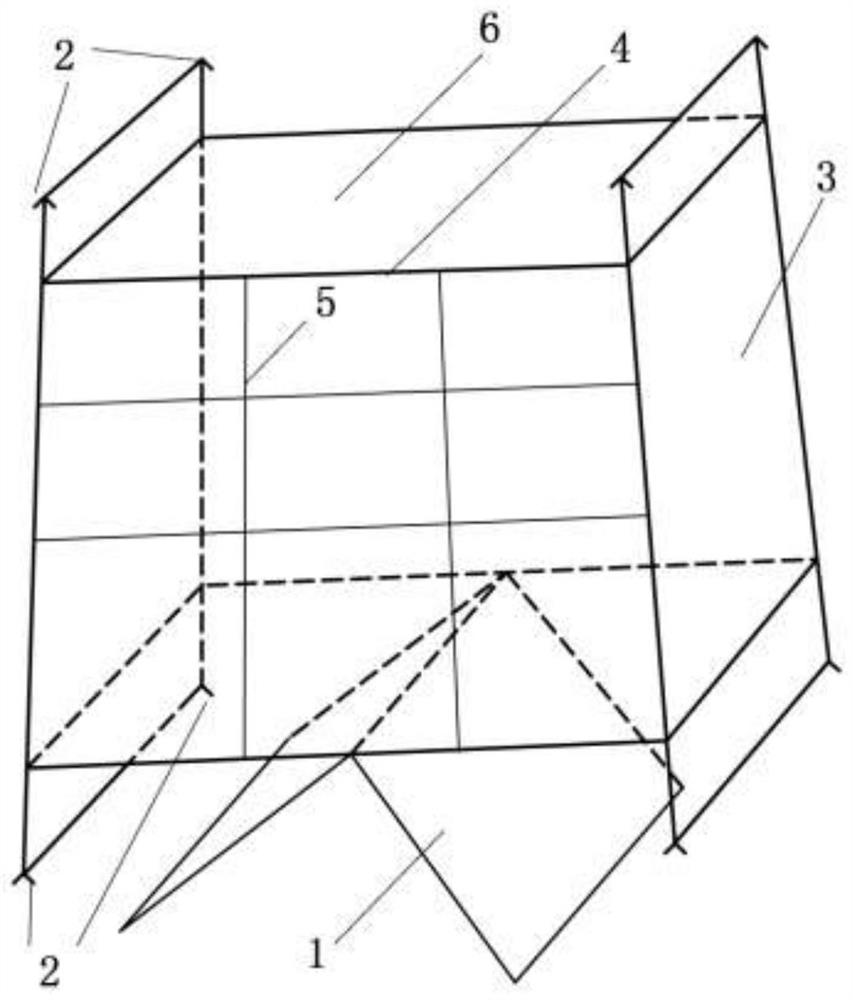

[0059] combine figure 1 , each box module includes a main frame 4, the main frame 4 is a cube frame, length*width*height=1.2*1*1m; the main frame 4 includes a discharge surface 1 and an access surface 6 of a ventilation module , the rest of the surface is wound by air-permeable material 3; the upper and lower ends of the main frame 4 are provided with angle steel 2, and the angle steel 2 of two adjacent container units up and down are matched and supported to realize stacking between the container units; the cross section of the angle steel 2 is "Inverted V" shape, and fixed on the upper and lower ends of the main frame 4 through a section of support plate.

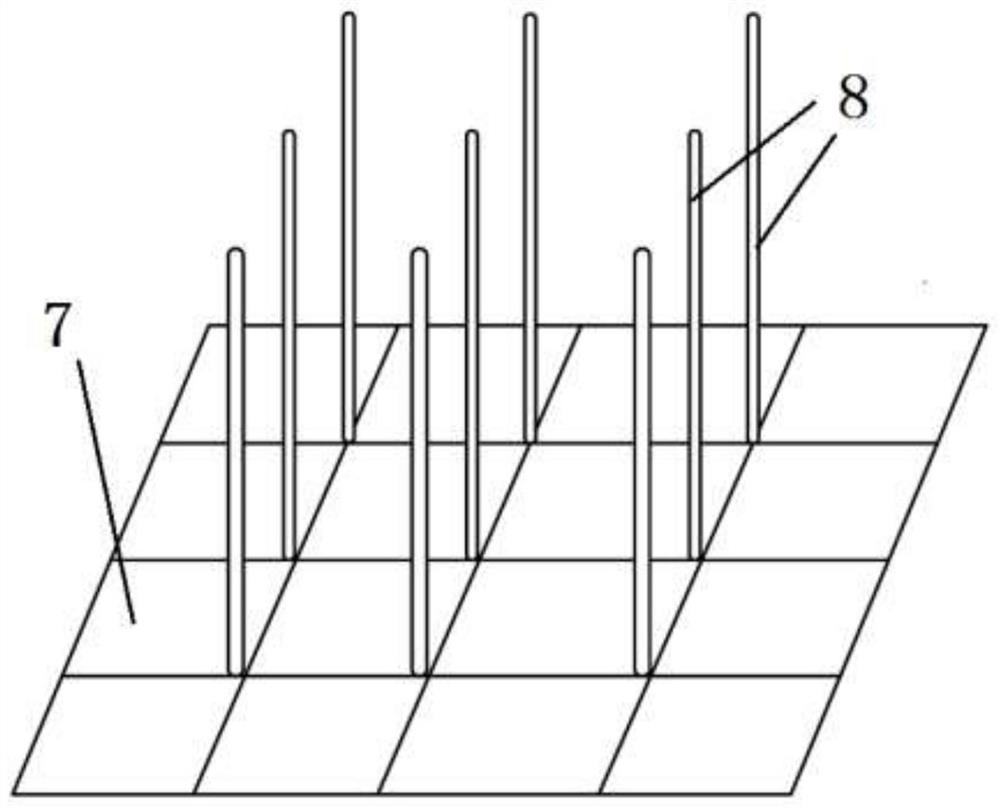

[0060] combine figure 2 , the ventilation module includes a bottom plate 7 and ventilation pipes 8 arranged on the bottom plate 7, and the ventilation pipes are arrang...

Embodiment 2

[0069] Other structures are the same as in Example 1, only the vent pipe 8) is implemented as follows: the vent pipe 8) is naturally formed after the long pipe is inserted into the material and pulled out.

Embodiment 3

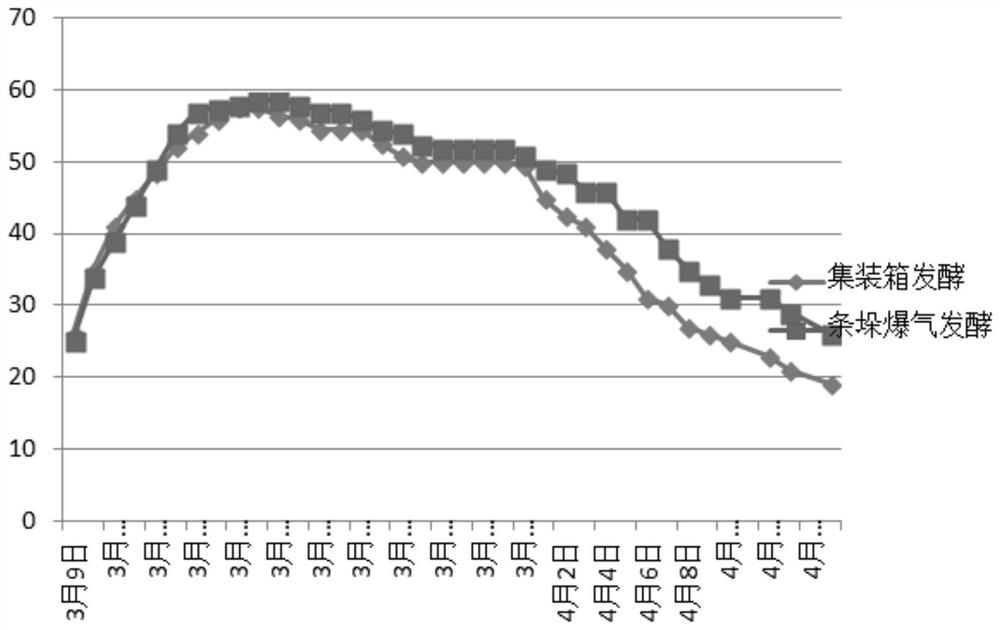

[0071] The stacked high fermentation container of Example 1 was used to carry out the non-powered aerobic fermentation of the following solid waste biomass container.

[0072] Test materials: mix cassava residue: mushroom residue: rice husk according to the mass ratio of 40:40:20, and inoculate the bacterial agent (according to the mass ratio of fermentation broth: yeast: bacillus: actinomycetes: rhizopus: nitrifying bacteria = 1:0.3 :1:1:0.3), inoculate 1 kg of bacterial agent per ton of material, mix evenly, and adjust the moisture to 65%. Carry out embodiment 1 piles of high fermentation container fermentation (with or without ventilation tube), strip-type overturning and throwing fermentation, intermittent gas explosion fermentation, measure the middle temperature of the material body every day, measure moisture after 40 days, and use rice seeding test to measure rot maturity and stability sex.

[0073] 3.1 Fermentation effect of container fermentation and stack turning a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com