Heater module, method of manufacturing the heater module, and aerosol-generating device with the heater module

An aerosol generation and heater technology, which is applied in induction heating devices, electric heating devices, induction heating, etc., can solve problems such as stability and energy efficiency reduction, and achieve the effect of improving heating performance and stability and reducing heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The best solution for carrying out the invention

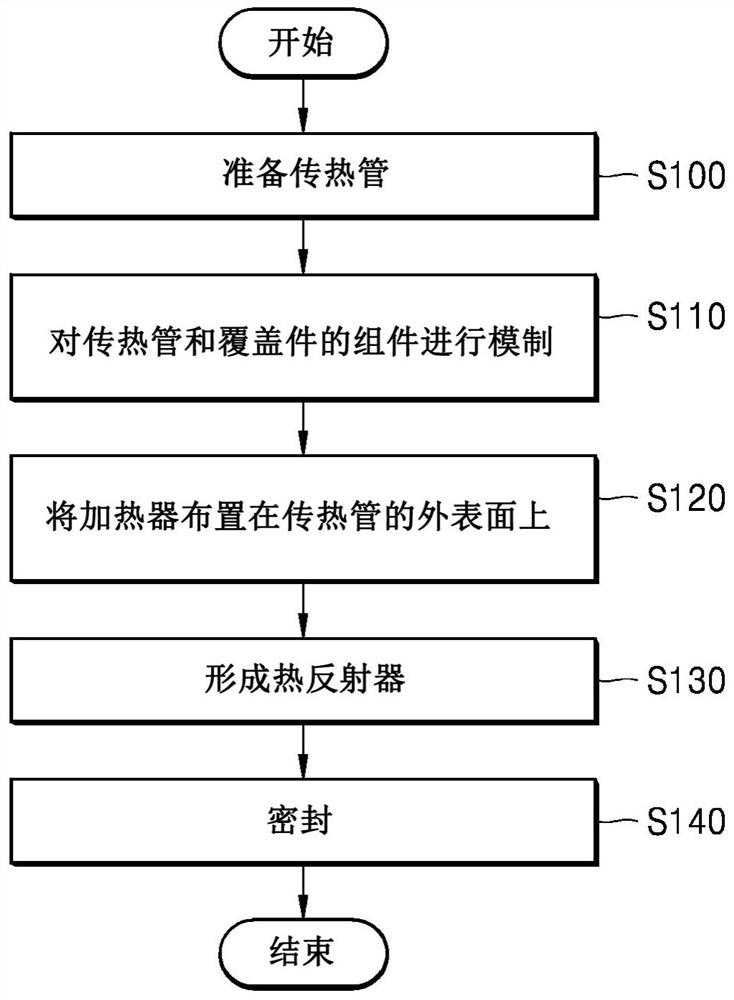

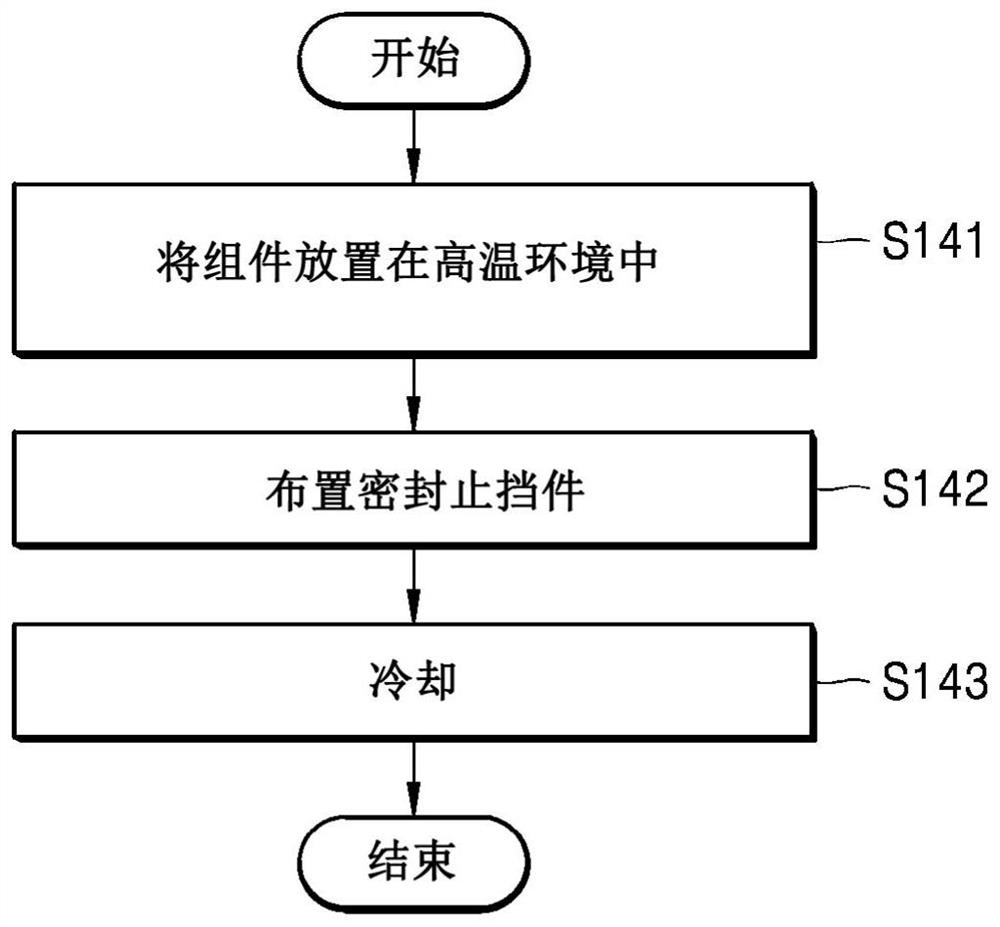

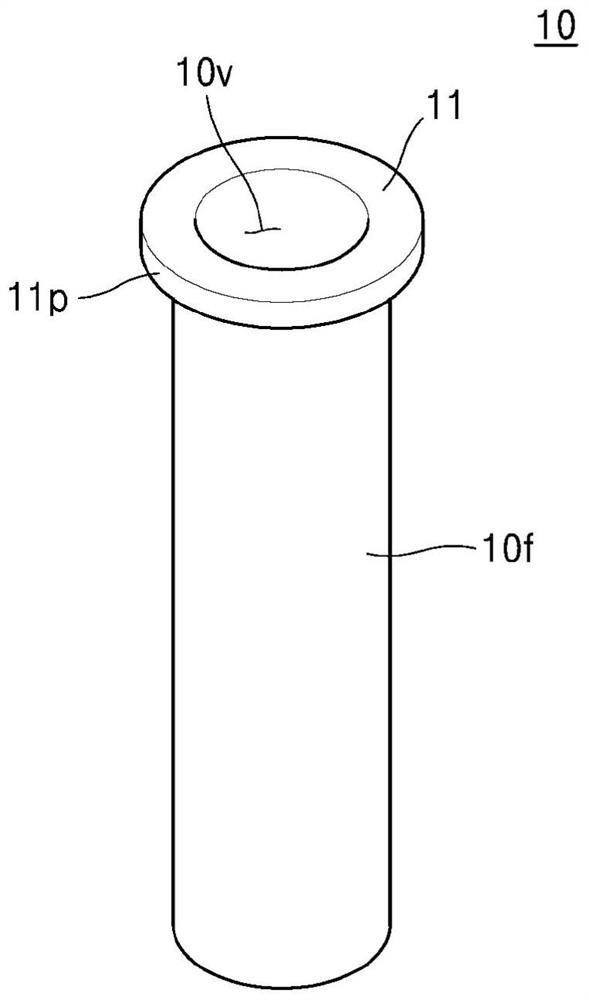

[0022] A method of manufacturing a heater module according to an embodiment includes: preparing a heat transfer tube having a hollow shape and including a thermally conductive material; forming an assembly of the heat transfer tube and a cover by insert molding such that one end of the cover is integrally coupled To the end of the heat transfer tube, while the side wall of the cover is spaced apart from the outer surface of the heat transfer tube and surrounds the heat transfer tube, in insert molding, the heat transfer tube is placed in the mold and the resin is injected into the mold ; arranging the heater on the outer surface of the heat transfer tube; and sealing the space between the heat transfer tube and the cover with a sealing stopper so that the internal pressure of the space is lower than atmospheric pressure.

[0023] A heater module according to an embodiment includes: a heat transfer tube having a hollow s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com