Forward osmosis membrane with two-dimensional MOFs as middle layer and preparation method of forward osmosis membrane

A technology of intermediate layer and support layer, applied in semi-permeable membrane separation, chemical instruments and methods, osmotic/dialysis water/sewage treatment, etc., can solve the problems of low efficiency, easy pollution of TFC membrane, etc. Operational efficiency, strong interaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

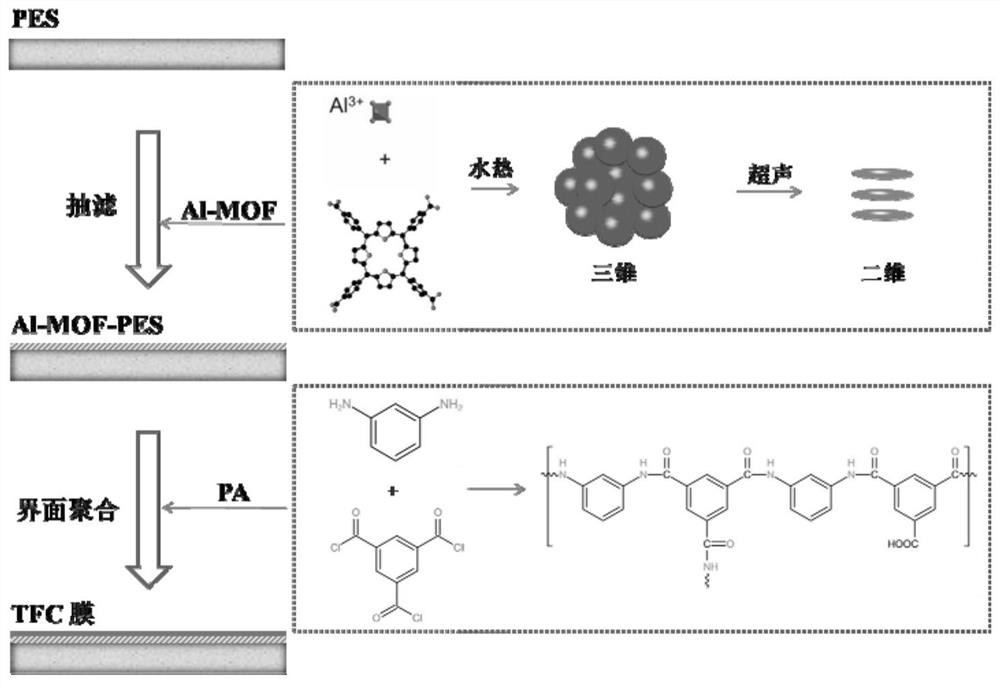

[0040] A method for preparing two-dimensional MOFs as a TFC-FO membrane of an intermediate layer, comprising the steps of:

[0041] (1) Preparation of two-dimensional MOFs dispersion: 92.23 mg of aluminum nitrate nonahydrate and 14 mg of polyvinylpyrrolidone were dissolved in 150 mL of N,N-dimethylformamide, which was stock solution A. Another 200mg of tetracarboxyphenylporphyrin was dissolved in 200mL of N,N-dimethylformamide, which was stock solution B. Then, the A and B stock solutions were mixed evenly in a glass bottle with a cap at a volume ratio of 2:1. The mixture was reacted at 120°C for 18h. After the reaction solution was cooled, the sample was collected by centrifugation, and the sample was washed three times with N,N-dimethylformamide and ethanol, respectively, to obtain the three-dimensional Al-MOF material. The three-dimensional Al-MOF material was dissolved in ethanol, and the two-dimensional Al-MOF material was obtained by ultrasonication at room temperature...

Embodiment 2

[0048] A method for preparing a TFC-FO membrane with two-dimensional MOFs as the middle layer, the difference from Example 1 is: under a pressure of 0.2 MPa, 125.6 mL of the dispersion is suction-filtered onto the polyethersulfone support layer. Subsequently, the film is fixed with a plate frame, and an appropriate amount (the amount is the same as in Example 1, the same below) of 2% m-phenylenediamine solution is poured on the surface of the film and soaked for 1 min. After soaking, use a rubber roller to remove the residual m-phenylenediamine solution on the film surface. , and then take an appropriate amount (the same amount as in Example 1, the same below) of 0.1% trimesoyl chloride solution and pour it onto the membrane surface to react for 2 minutes. After draining, place the membrane in a hot water bath at 100° C. for thermal crosslinking for 5 minutes. That is to obtain the TFC-FO membrane with the two-dimensional MOFs as the middle layer.

[0049] According to the tes...

Embodiment 3

[0053] A method for preparing a forward osmosis membrane with two-dimensional MOFs as the middle layer. The difference from Example 1 is that: under a pressure of 0.2 MPa, 188.4 mL of the dispersion is suction-filtered onto the polyethersulfone support layer. Then fix the membrane with a plate frame, take an appropriate amount of 2% m-phenylenediamine solution and pour it on the surface of the membrane to soak for 1 min. The acid chloride solution was poured onto the membrane surface to react for 2 minutes, and after draining, the membrane was placed in a hot water bath at 100°C for 5 minutes of thermal crosslinking to obtain the TFC-FO membrane with the two-dimensional MOFs as the middle layer.

[0054] According to the test method of Example 1, the water flux of the TFC-FO membrane that measures the two-dimensional MOFs as the intermediate layer is 23.4L m -2 h -1 , the reverse salt flux is 0.37g m -2 h -1 .

[0055] Compared with Comparative Example 1, the water flux of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com