Power distribution cabinet for real-time temperature monitoring without continuous power supply

A real-time temperature, continuous power supply technology, applied in substation/distribution device casings, thermometers, thermometers with physical/chemical changes, etc., can solve problems such as inability to monitor temperature and failure of temperature-sensitive probes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Preparation of thermosensitive probes

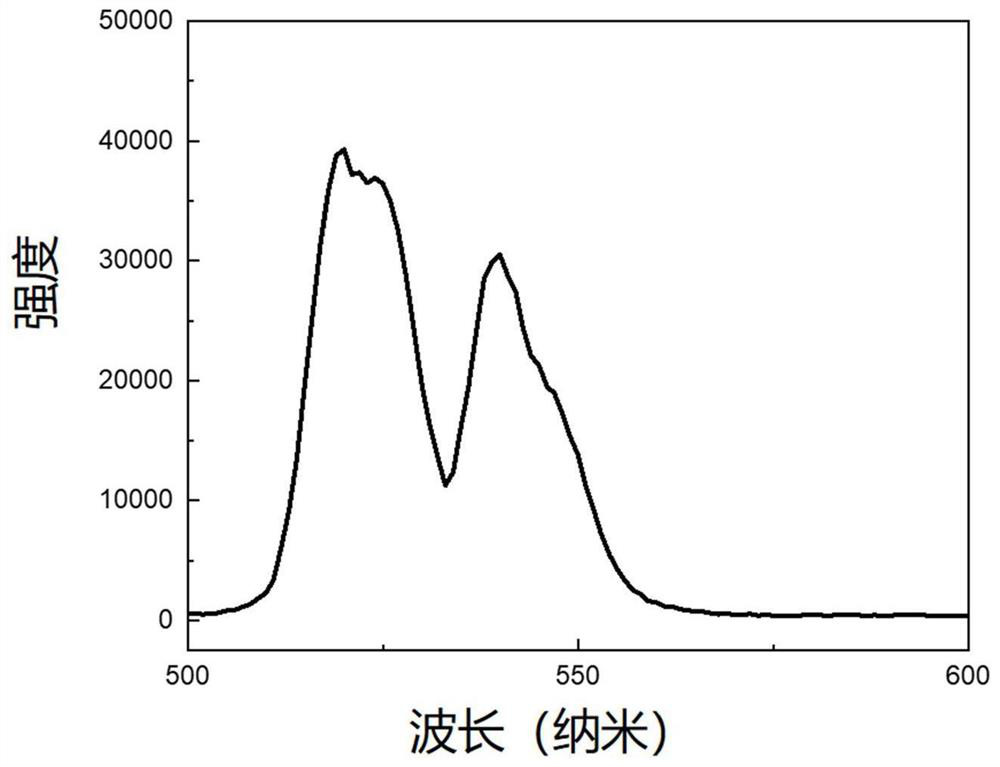

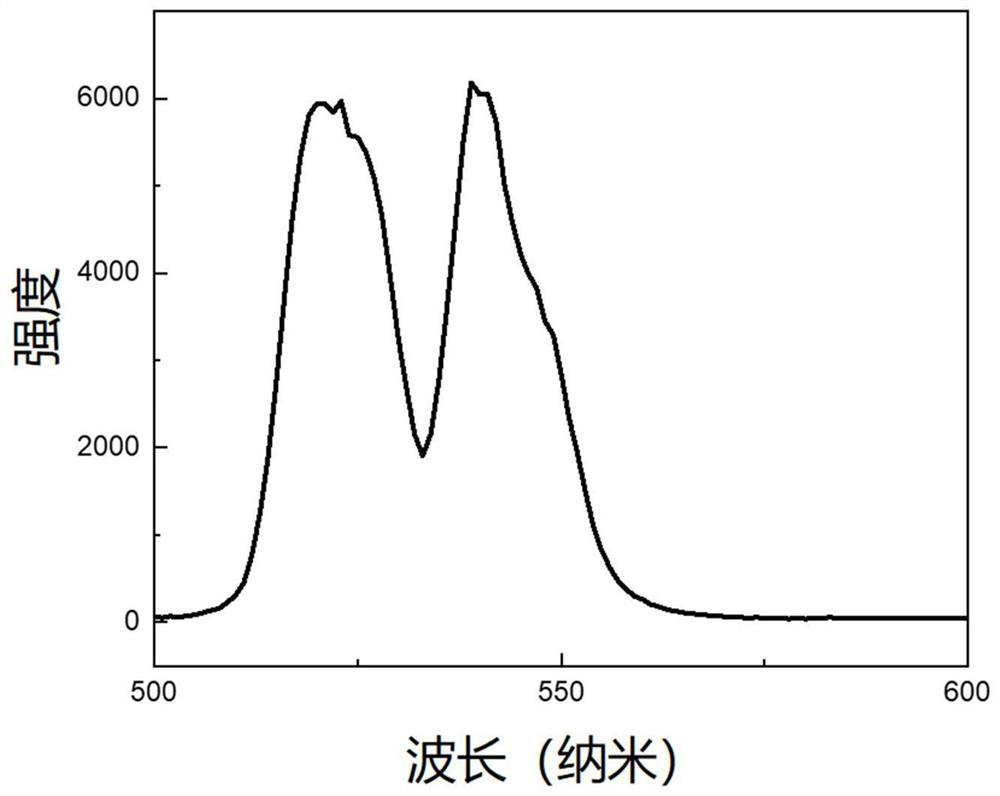

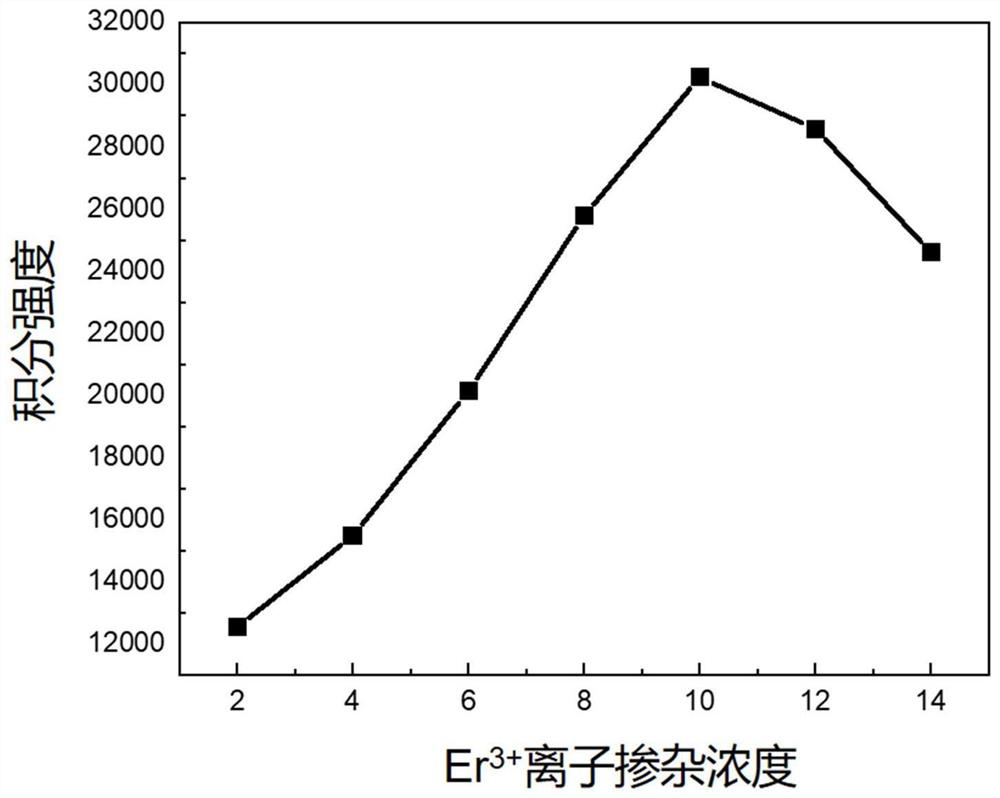

[0031] Add 1 mmol of yttrium chloride, 10 milliliters of oleic acid, and 15 milliliters of octadecene into a 50 milliliter three-necked bottle at room temperature, and raise the temperature to 160 o C, and kept warm for 50 minutes; after the reaction was completed and cooled to room temperature, 3 mmol of ammonium fluoride was added, and then the temperature was rapidly raised to 310 °C under nitrogen protection conditions. oC , and incubated for 90 minutes; after the solution was cooled to room temperature, ethanol was added to centrifuge to obtain a precipitate, and the product was washed with a mixture of ethanol:cyclohexane at a ratio of 3:1, and then at 60 oC YF is obtained after drying 3 Product; With 0.9 millimoles of lutetium chloride, 0.1 millimoles of erbium chloride, 0.05 millimoles of lithium acetate, 10 milliliters of oleic acid, 15 milliliters of octadecenes, join in the 50 milliliters of three-necked flasks at room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com