Constant-tension winch hydraulic system

A hydraulic system and constant tension technology, which is applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, hoisting devices, etc., can solve the problems of system energy loss, hydraulic oil viscosity reduction, efficiency reduction, etc., and achieve high efficiency and constant tension. Effects of tension control, reduction of overflow loss, and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

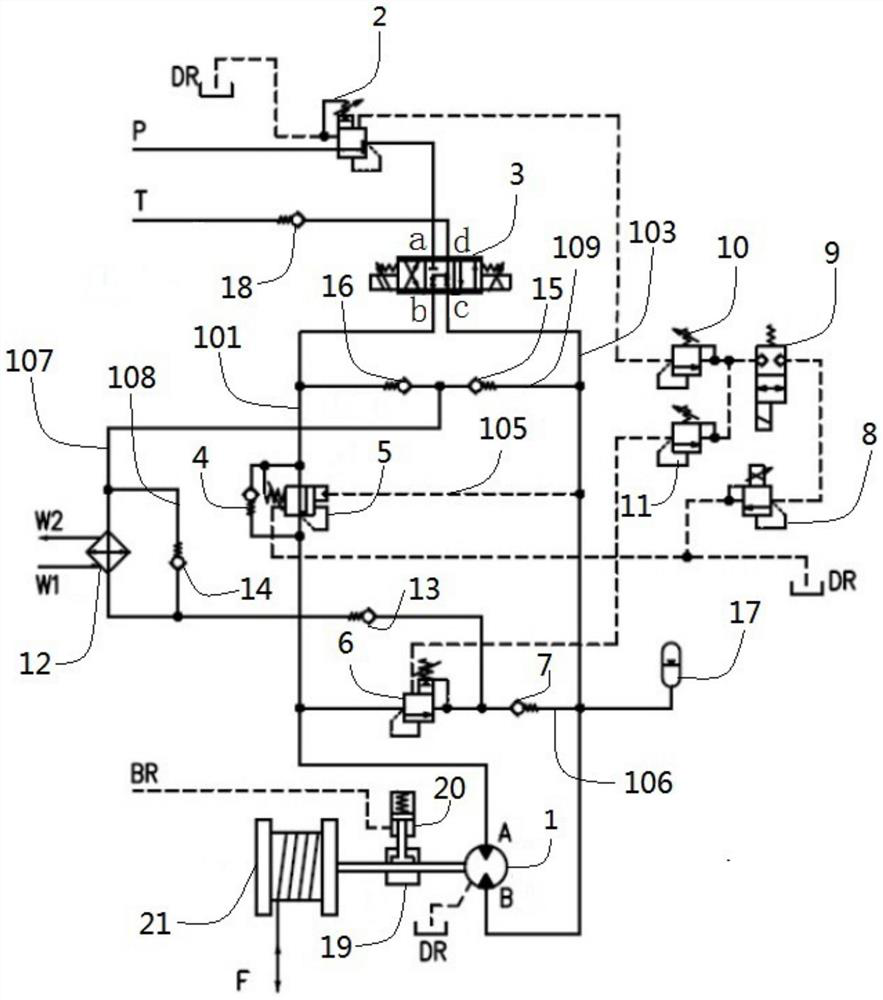

[0027] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings, in which the same reference numerals represent the same components.

[0028] This embodiment provides a constant tension winch hydraulic system, such as figure 1 As shown, it includes power pump group, hydraulic motor 1, pressure reducing valve 2, main control valve 3, one-way switching valve group, main relief valve 6, second one-way valve 7, control relief valve 8, reversing valve 9. First relief valve 10, second relief valve 11, radiator 12, third check valve 13, bypass check valve 14, fifth check valve 15, sixth check valve 16, energy storage Device 17 and back pressure check valve 18.

[0029] Among them, the power pump group is a load-sensitive variable pump, the pressure reducing valve 2 is a pilot pressure reducing valve, the main control valve 3 is an electric proportional valve, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com