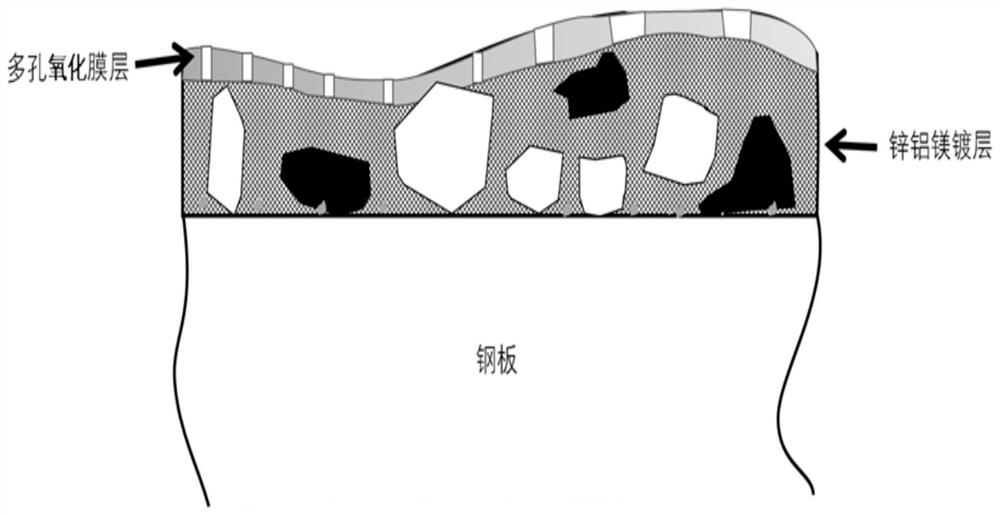

Easily degreased coated steel plate, preparation method thereof and painted steel plate

A technology of coating steel plate and coating, applied in coating, hot dipping process, solid diffusion coating, etc., can solve problems such as ineffective degreasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

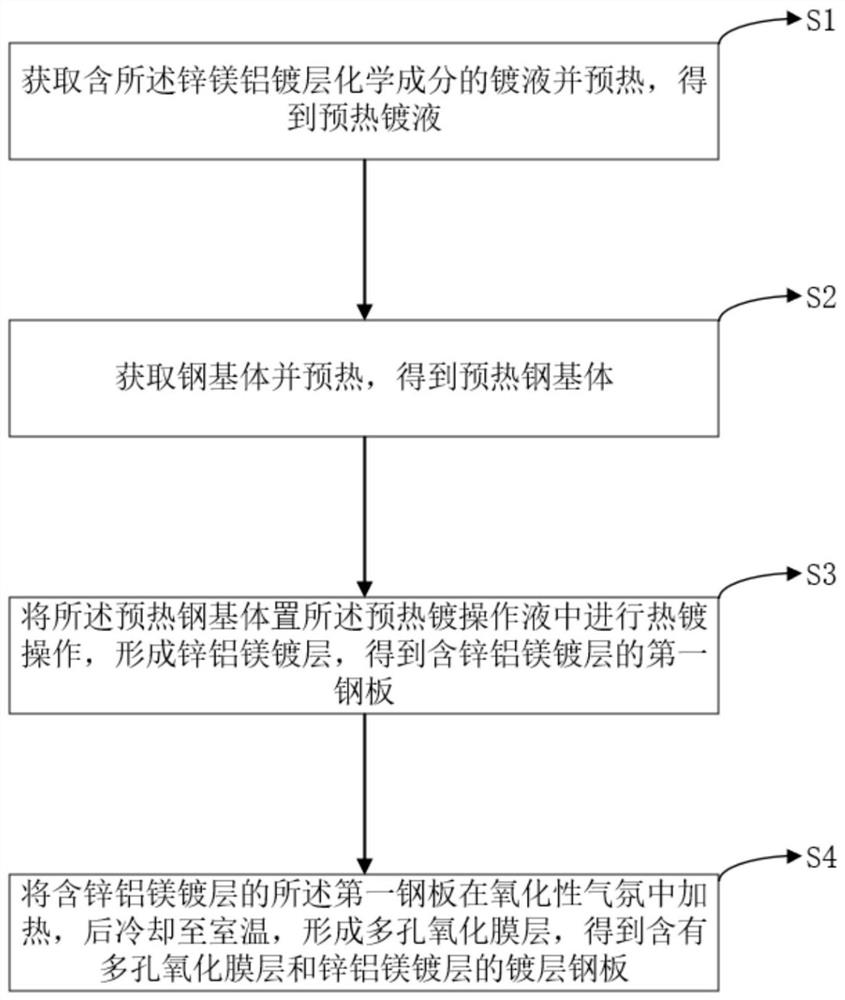

[0034] Such as figure 2 , In one embodiment of the present application, there is provided an easy method for preparing defatted plated steel sheet, the method comprising:

[0035] . S1 obtain a bath containing the chemical composition of the magnesium aluminum coating and preheated to afford preheating bath;

[0036] As an alternative embodiment, the preheating temperature of the bath was 400 ℃ -500 ℃, the preheating temperature of the steel substrate of 400 ℃ -500 ℃;

[0037]In the present application, it is an object of controlling the temperature of 400 ° C to 500 ° C in the preheating plating solution to prevent too low of the plating solution; when the temperature range is too large, since the steel sheet is at a higher temperature. In the plating solution, the Fe element in the steel sheet will quickly react rapidly in the plating solution, forming a coarse-containing compound particulate matter containing Si and Mg, and deteriorating the toughness of the plating layer, resu...

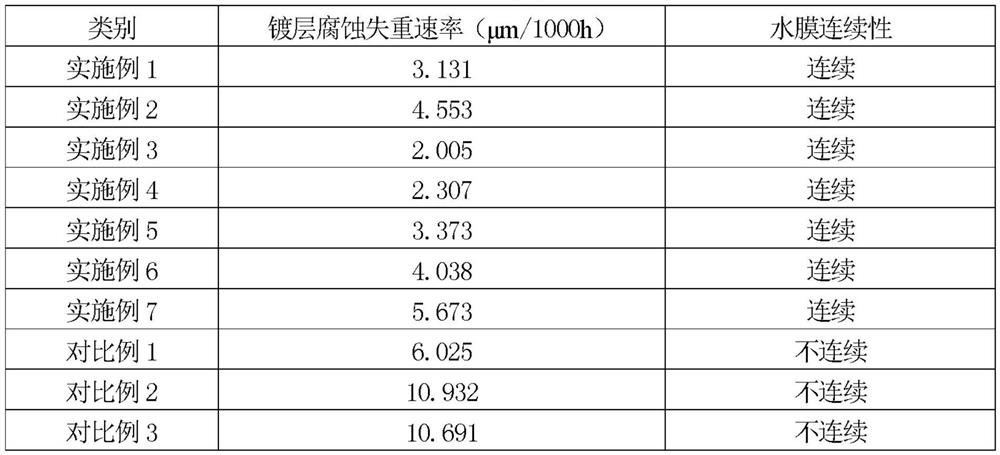

Embodiment 1

[0048] The chemical composition of zinc aluminum magnesium plating is: mg: 1%, Al: 1%, margin is Zn and inevitable impurity elements;

[0049] The porosity of the porous oxide film is 20%, and the hole depth accounts for 100% of the thickness of the porous oxide film layer. The thickness of the porous oxide film is 100 nm, and the aperture depth is 100 nm;

[0050] The mass fraction of oxygen in the oxidative atmosphere is 0.3%, and the heating temperature in the controlled oxidizing atmosphere is 100 ° C, and the heating time is 10 s in the oxidizing atmosphere;

[0051] The preheating plating solution has a temperature of 480 ° C, and the temperature of the preheating steel matrix is 480 ° C.

Embodiment 2

[0053] The chemical ingredient of zinc aluminum magnesium plating is: mg: 1.2%, Al: 2%, margin is Zn and inevitable impurity elements;

[0054] The porosity of the porous oxide film is 25%, the hole depth accounts for 97% of the thickness of the porous oxide film layer, and the thickness of the porous oxide film is 100 nm, and the aperture depth is 97 nm;

[0055] The mass fraction of oxygen in the oxidation atmosphere is 0.8%, and the heating temperature in the oxidizing atmosphere is 120 ° C, and the heating time is 20 s in the oxidizing atmosphere;

[0056] The temperature of the preheating plating solution was 400 ° C, and the temperature of the preheating steel matrix was 430 ° C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com