Cover annealing method for high-Cr-Si alloyed hot-formed steel

A technology of hot forming steel and bell annealing, which is applied in the field of heat treatment, can solve the problems of limited bending performance of martensitic structure, poor uniformity of structure and performance, large performance fluctuation, etc., and achieve high overall yield, high utilization rate, and improved uniformity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

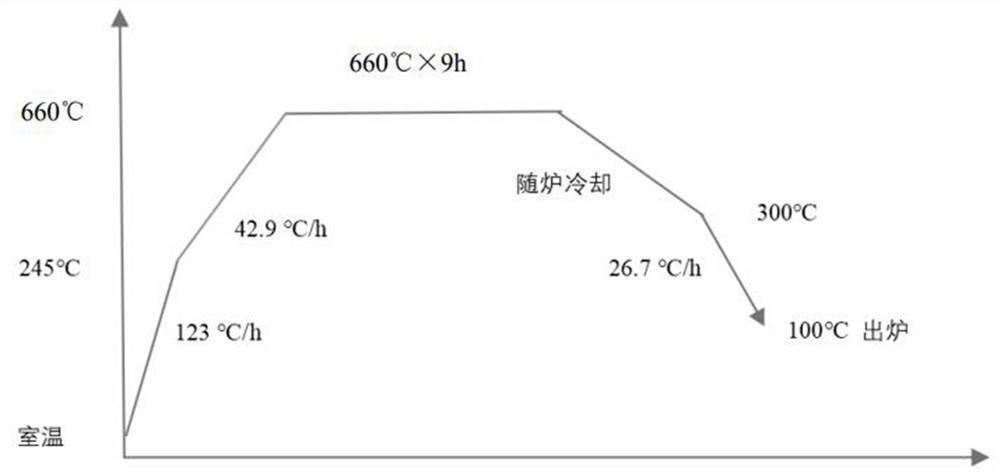

[0037] Prepare Cr-Si alloyed 1700MPa grade hot-rolled coating-free hot-formed steel with a thickness of 1.5mm, and add the cover-back step after hot-rolling and preparing steel coils:

[0038] (1) Controlled rolling and controlled cooling treatment

[0039] The chemical composition of the alloy billet by weight percentage is: C: 0.30%, Mn: 0.8%, Si: 1.8%, S: 0.005%, P: 0.008%, Al: 0.01%, Cr: 3.0%, Nb: 0.03%, V: 0.01%, Ti: 0.03%, Cu: 0.05%, and the balance is Fe and other unavoidable impurities.

[0040] The continuous casting slab with the above components was heated to 1300°C with the furnace and held for 2.5 hours; after one descaling, the furnace-generated iron scale was removed, the rough rolling start temperature was 1170°C, and after 6 passes of rough rolling, the rough rolling The total reduction rate is 87%, and the thickness of the intermediate billet is 30.55mm; after removing the secondary oxide scale before finish rolling, it is rolled into a hot-rolled plate with...

Embodiment 3

[0055] To prepare Cr-Si alloyed 1500MPa-grade hot-rolled coating-free hot-formed steel with a thickness of 3.5mm, add the cover-back step after hot-rolling and preparing steel coils:

[0056] (1) Controlled rolling and controlled cooling treatment

[0057] The chemical composition of the alloy billet by weight percentage is: C: 0.21%, Mn: 2.2%, Si: 2.6%, S: 0.008%, P: 0.007%, Al: 0.05%, Cr: 1.5%, Nb: 0.01%, V: 0.04%, Ti: 0.02%, Cu: 0.09%, and the balance is Fe and other unavoidable impurities.

[0058] The continuous casting slab with the above components is heated to 1285°C with the furnace and kept for 2 hours; after one descaling, the furnace scale is removed, the rough rolling start temperature is 1108°C, after 6 passes of rough rolling, the rough rolled The total reduction rate is 86%, and the thickness of the intermediate billet is 32.5mm; after removing the secondary oxide scale before finish rolling, it is rolled into a hot-rolled plate with a thickness of 3.5mm by 7 ...

Embodiment 5

[0071] To prepare Cr-Si alloyed 1500MPa-grade hot-rolled coating-free hot-formed steel with a thickness of 6.0mm, add the cover step after hot-rolling and preparing steel coils:

[0072] (1) Controlled rolling and controlled cooling treatment

[0073] The chemical composition of the alloy billet by weight percentage is: C: 0.15%, Mn: 3.1%, Si: 0.8%, S: 0.005%, P: 0.008%, Al: 0.01%, Cr: 3.6%, Nb: 0.05%, V: 0.01%, Ti: 0.03%, Cu: 0.05%, and the balance is Fe and other unavoidable impurities.

[0074] The continuous casting slab with the above components was heated to 1284°C with the furnace and held for 2 hours; after one descaling, the furnace oxide scale was removed, and the starting temperature of rough rolling was 1118°C. After 6 passes of rough rolling, the rough rolling The total reduction rate is 83%, and the thickness of the intermediate billet is 40mm; after removing the secondary oxide scale before finish rolling, it is rolled into a hot-rolled plate with a thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com