Anti-aging auxiliary agent bag and preparation method thereof and application of anti-aging auxiliary agent bag in carbon fiber prepreg

A carbon fiber prepreg and anti-aging technology, which is applied in the field of special additives, can solve the problems of large precipitation risk, unsatisfactory formula design, and high-temperature curing requirements of antioxidants, and achieve good synergy and improve thermal oxygen resistance. Effects of Aging and Photoaging on Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

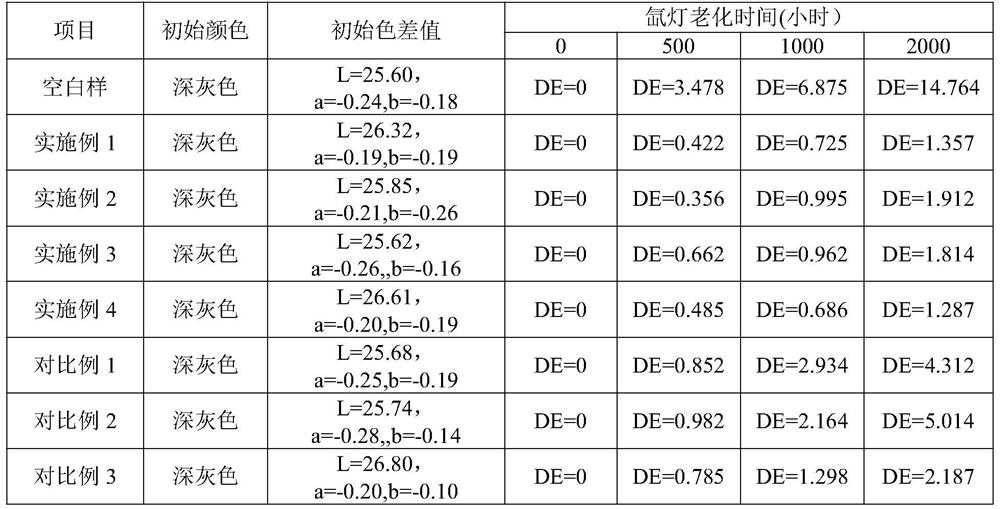

Examples

Embodiment 1

[0030] The anti-aging additive package product applied to epoxy resin cured carbon fiber prepreg in this embodiment includes the following components in mass percentage:

[0031] Liquid phenylmethylamine UV absorber: 60%;

[0032] Liquid light stabilizer UV-292: 30%;

[0033] Antioxidant 1076: 10%.

[0034] The anti-aging aid package product is prepared by the following method:

[0035] (1) After weighing the liquid phenylmethylamine ultraviolet absorber and the liquid light stabilizer UV-292 according to the above mass percentages, put them in a 304 stainless steel barrel and mix them with a high mixer for later use.

[0036] (2) Weigh the solid antioxidant 1076 powder according to the above mass percentage and put it into the liquid mixture obtained in step (1); raise the temperature of the mixing tank to 80°C, and stir until the solid antioxidant powder is completely Dissolve until the product is clear and transparent, pass through a 400-mesh stainless steel filter, and ...

Embodiment 2

[0038] The anti-aging additive package product applied to epoxy resin cured carbon fiber prepreg in this embodiment includes the following components in mass percentage:

[0039] Liquid UV absorber UV-400: 45%;

[0040] Liquid light stabilizer UV-292: 40%;

[0041] Antioxidant 1076: 15%.

[0042] The anti-aging aid package product is prepared by the following method:

[0043](1) Weigh the liquid ultraviolet absorber UV-400 and the liquid light stabilizer UV-292 according to the above mass percentages, put them in a 304 stainless steel bucket and mix them with a high mixer for later use.

[0044] (2) Weigh the solid antioxidant 1076 powder according to the above mass percentage and put it into the liquid mixture obtained in step (1); raise the temperature of the mixing tank to 80°C, and stir until the solid antioxidant powder is completely Dissolve until the product is clear and transparent, pass through a 400-mesh stainless steel filter, and get a transparent liquid anti-ag...

Embodiment 3

[0046] The anti-aging additive package product applied to epoxy resin cured carbon fiber prepreg in this embodiment includes the following components in mass percentage:

[0047] Liquid UV absorber UV 384-2: 60%;

[0048] Liquid light stabilizer UV-292: 25%;

[0049] Antioxidant 245: 15%.

[0050] The anti-aging aid package product is prepared by the following method:

[0051] (1) Weigh the liquid UV absorber UV 384-2 and the liquid light stabilizer UV-292 according to the above mass percentages, put them in a 304 stainless steel bucket and mix them with a high mixer for later use.

[0052] (2) Weigh the solid antioxidant 245 powder according to the above mass percentage and put it into the liquid mixture obtained in step (1); the temperature of the mixing tank is raised to 80°C, and stir until the solid antioxidant powder is completely Dissolve until the product is clear and transparent, pass through a 400-mesh stainless steel filter, and get a transparent liquid anti-agin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com